An enameled wire production line

An enameled wire and production line technology, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problems of low service life and poor sensitivity, and achieve the effect of convenient wiring, ensuring work sensitivity and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

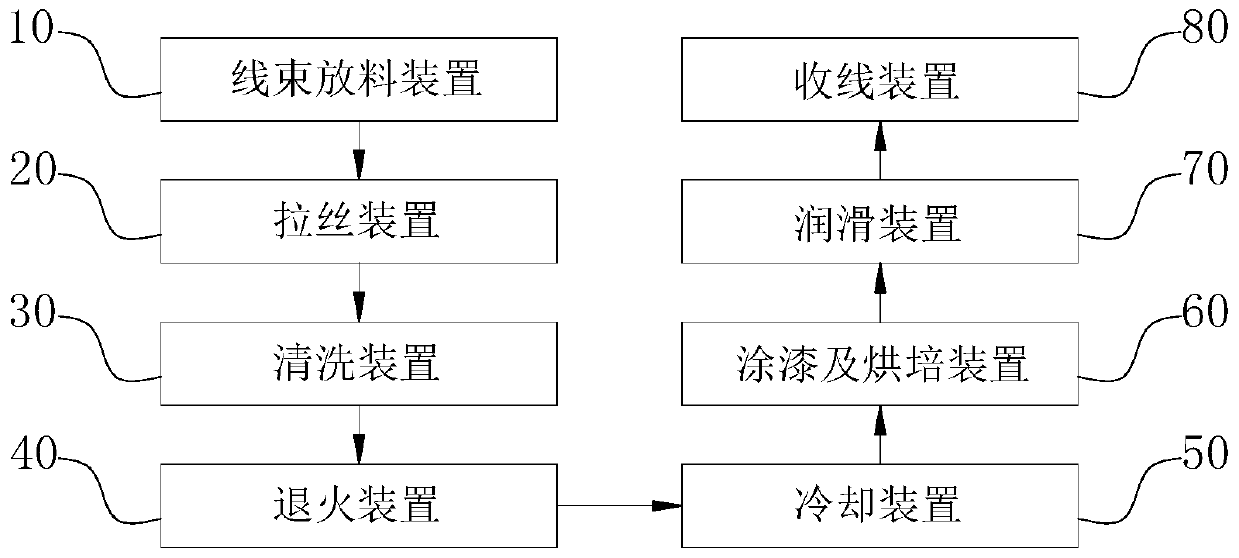

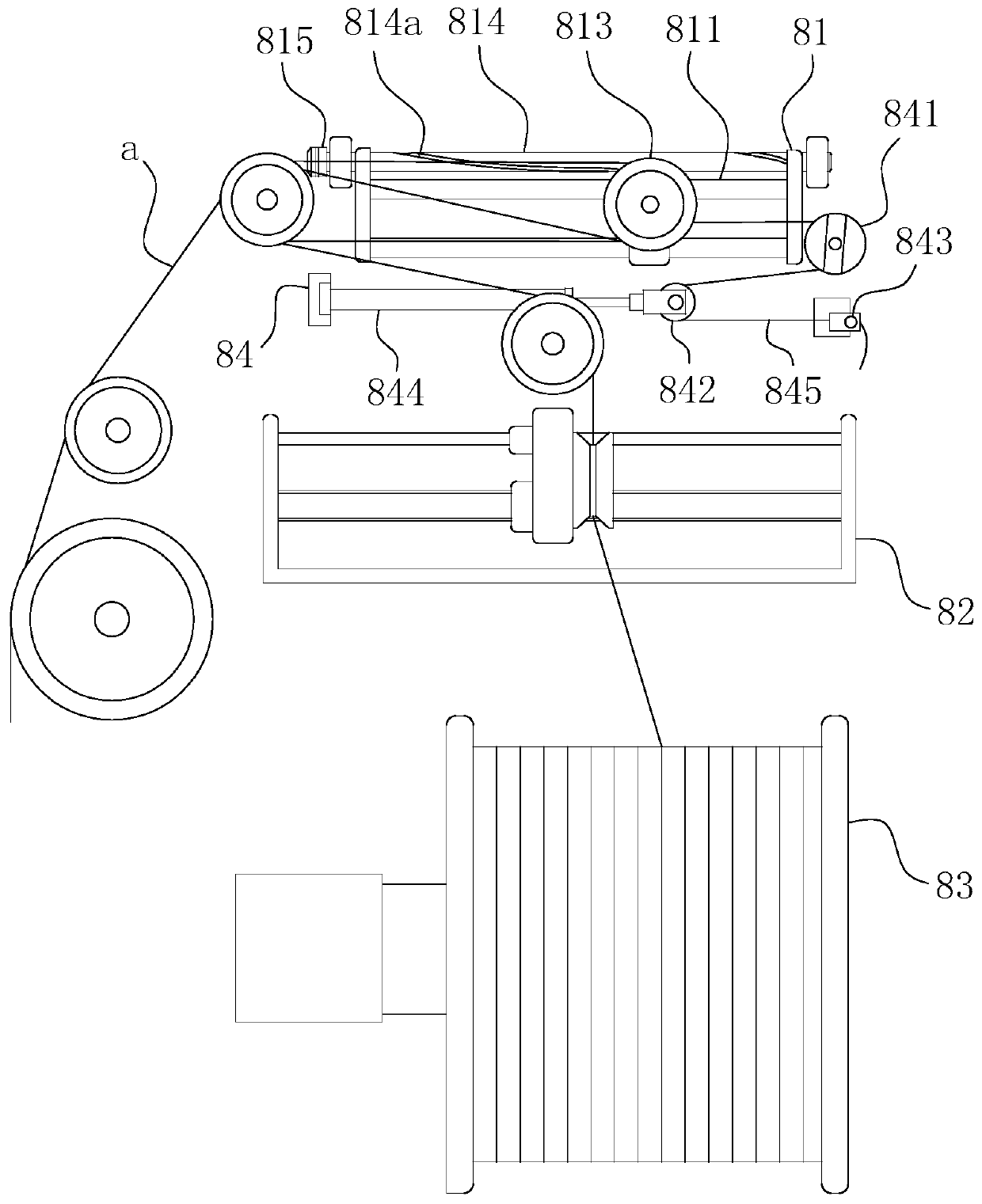

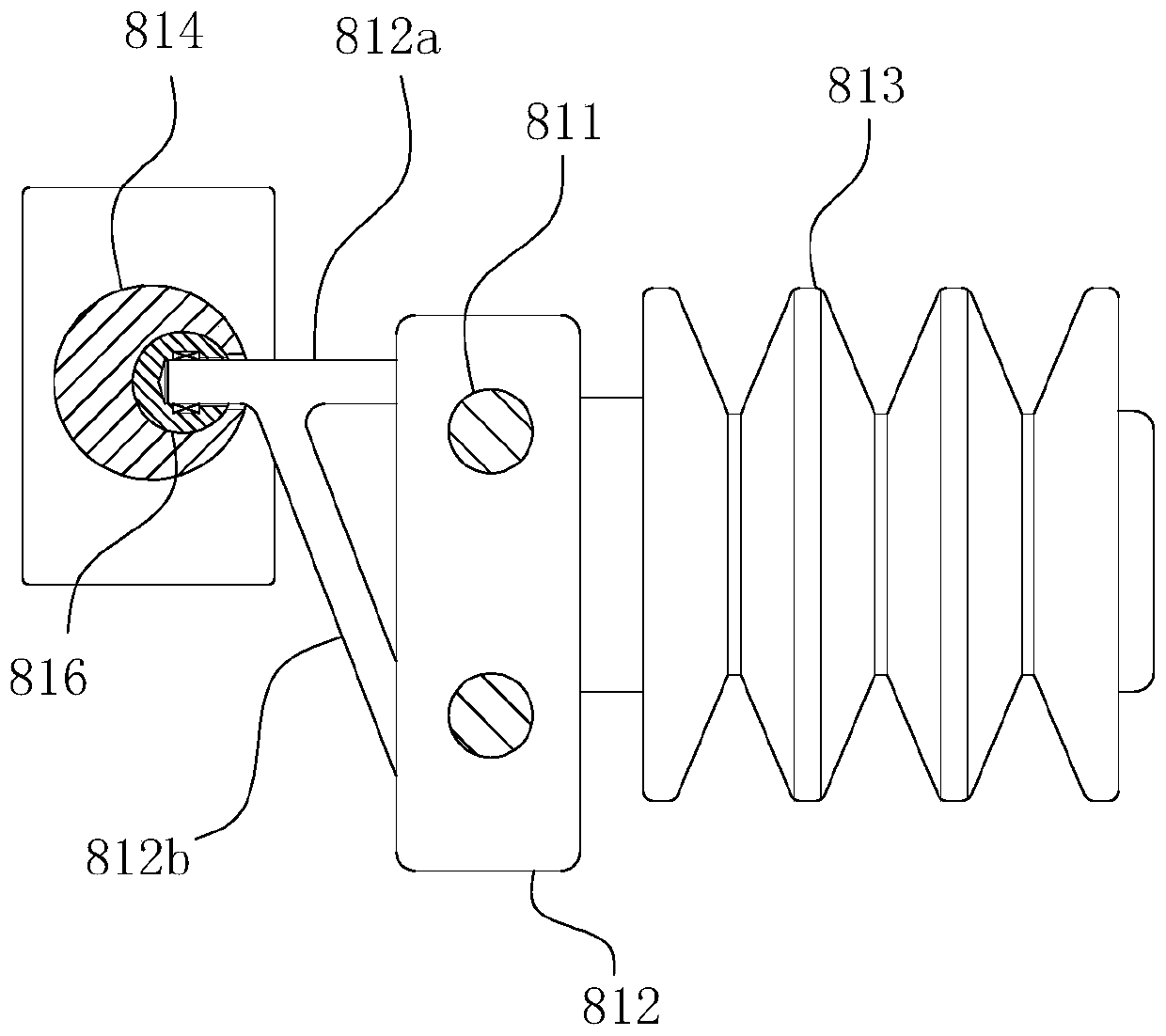

[0042] For ease of understanding, combined here Figure 1-4 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

[0043] The concrete implementation structure of the present invention can refer to figure 1 As shown, including the sequential settings along the direction of copper wire travel:

[0044] The wire harness unwinding device 10 is used to release the bare wire to be processed wound on the reel;

[0045] Wire drawing device 20, used for thinning the bare wire to the required specification;

[0046] The cleaning device 30 is used to clean the bare wire, and remove oil and particles on the surface of the bare wire after wire drawing;

[0047] An annealing device 40, used for annealing the bare wire after wire drawing and cleaning;

[0048] Cooling device 50, used for cooling the bare wire after annealing;

[0049] The painting and baking device 60 is used to paint the surface of the bare wire, and then bake and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com