An enameled wire production line

A production line, enameled wire technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of poor sensitivity of proximity switches, work wear, and large impact force of ball screws, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

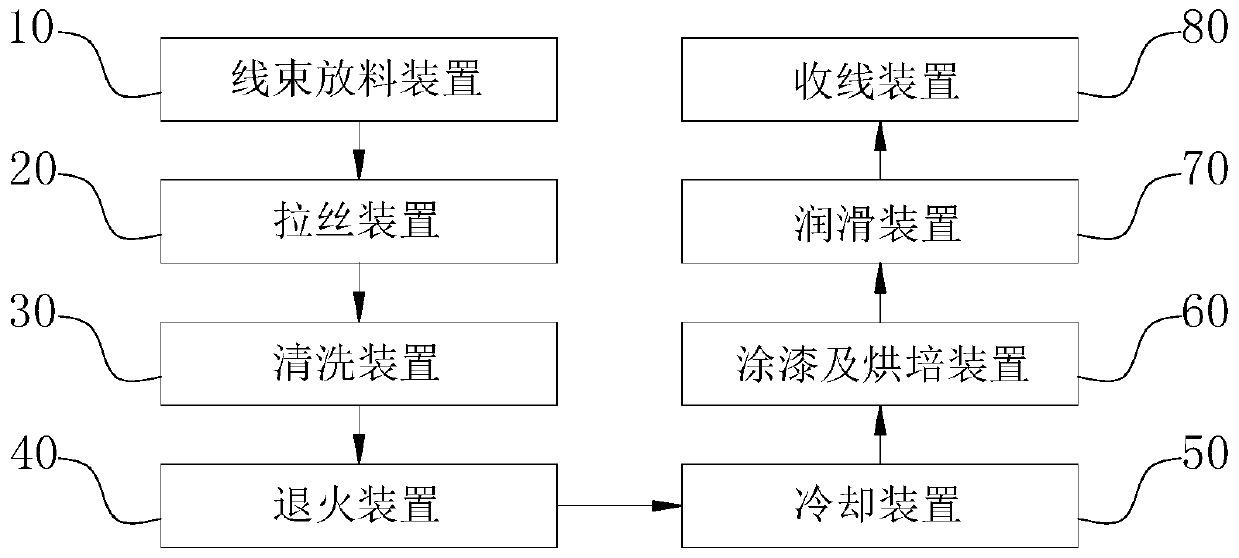

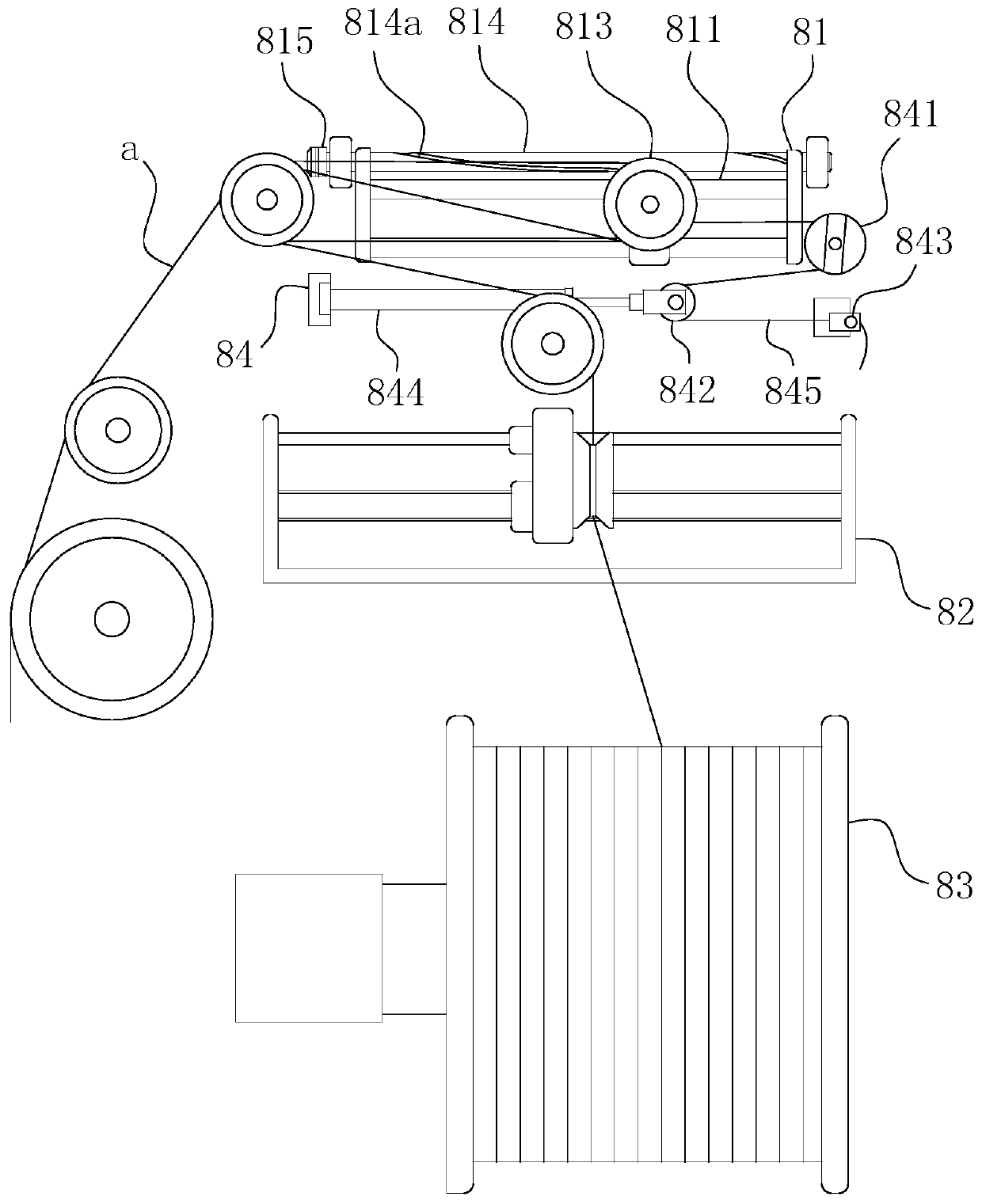

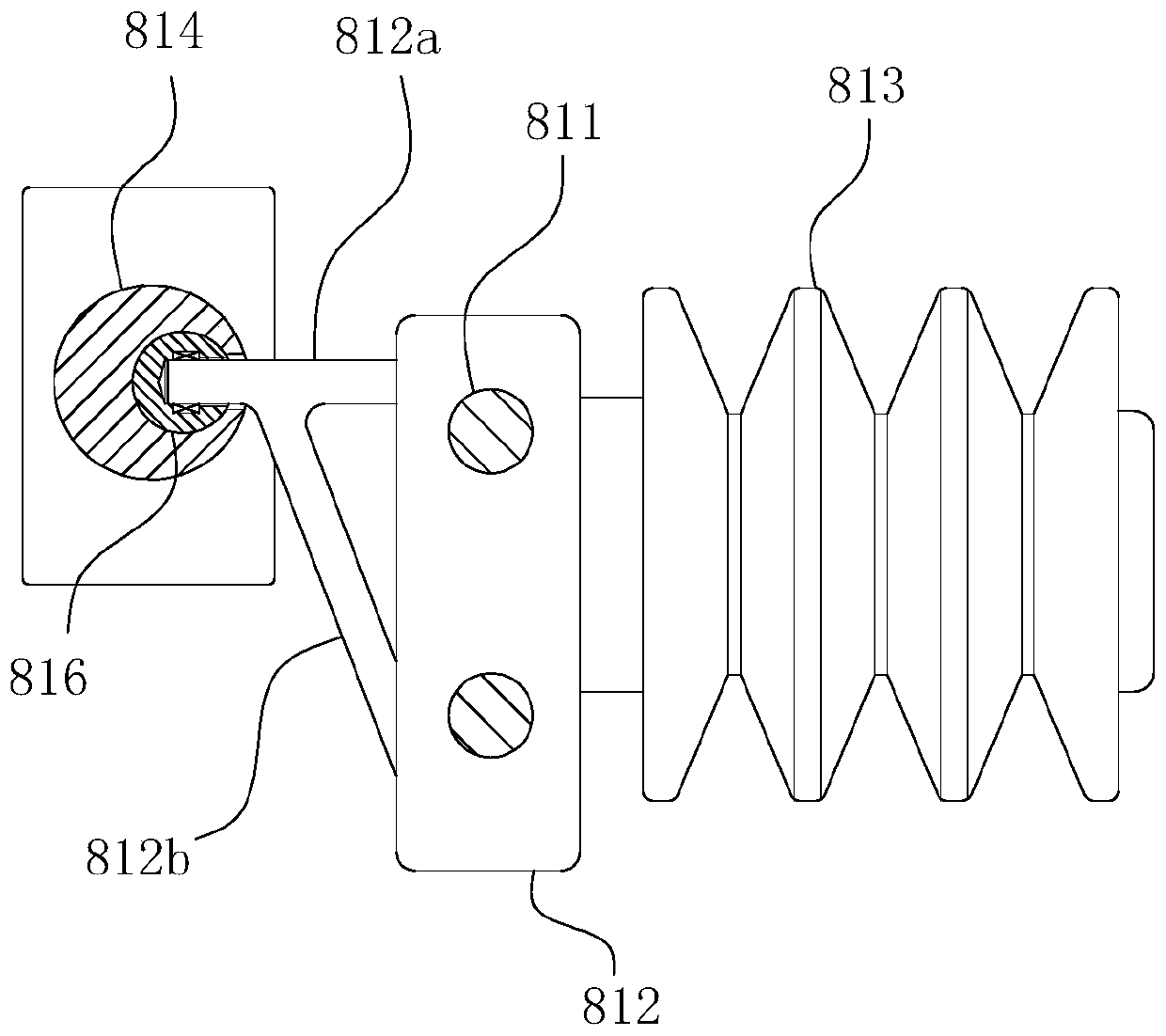

[0057] For ease of understanding, combine here Figure 1-6 The specific implementation structure and work flow of the present invention are further elaborated as follows:

[0058] The specific implementation structure of the present invention can refer to figure 1 As shown, including those set in sequence along the wire travel direction:

[0059] The wire harness unwinding device 10 is used to release the wire a to be processed wound on the reel;

[0060] The wire drawing device 20 is used to draw the wire a to the required specification;

[0061] The cleaning device 30 is used to clean the wire a, and remove oil and particles on the surface of the wire a after drawing;

[0062] The annealing device 40 is used for annealing the wire a after drawing and cleaning;

[0063] The cooling device 50 is used to cool the annealed wire a;

[0064] The painting and baking device 60 is used for painting the surface of the wire a, and baking and curing after painting to form the wire a;

[0065] Lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com