A kind of enameled wire production process

A production process, enameled wire technology, applied in the direction of insulation of conductors/cables, electrical components, circuits, etc., can solve the problems of reduced service life and working reliability, wear and tear, and poor sensitivity of proximity switches, etc., to achieve production efficiency and finished products. The effect of quality improvement, reasonable process steps, softening and breakdown improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

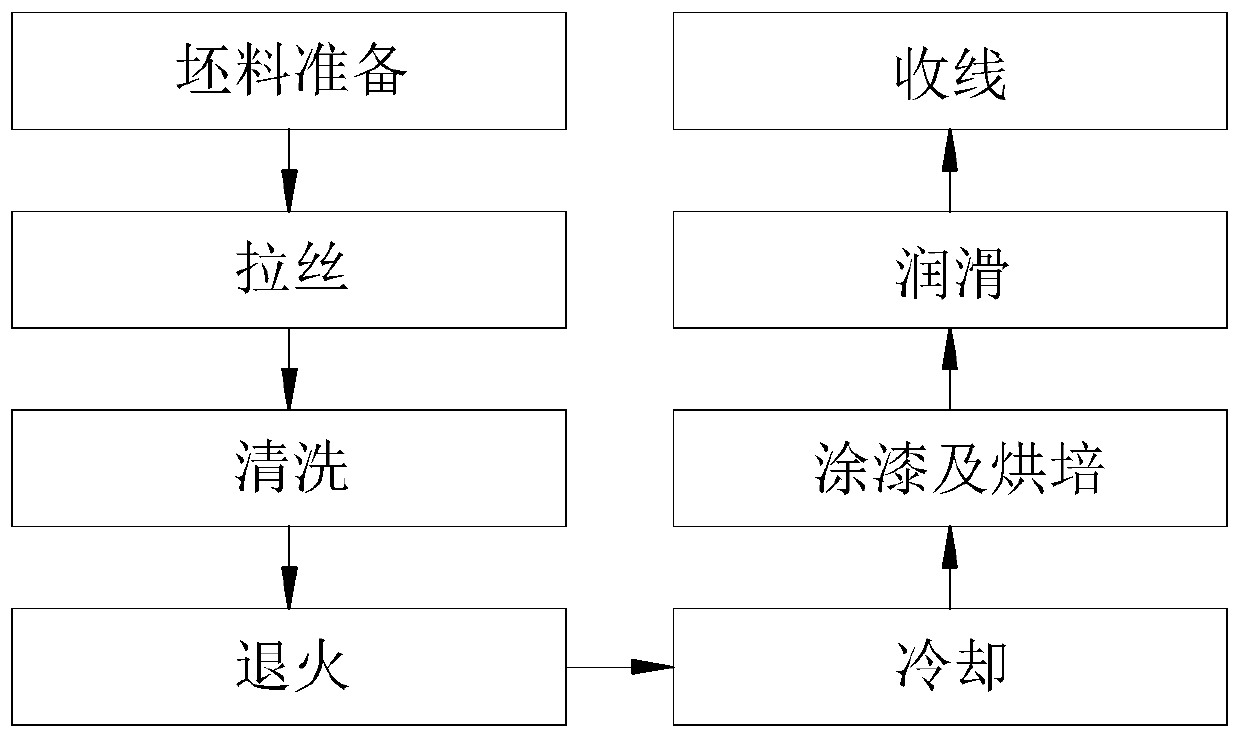

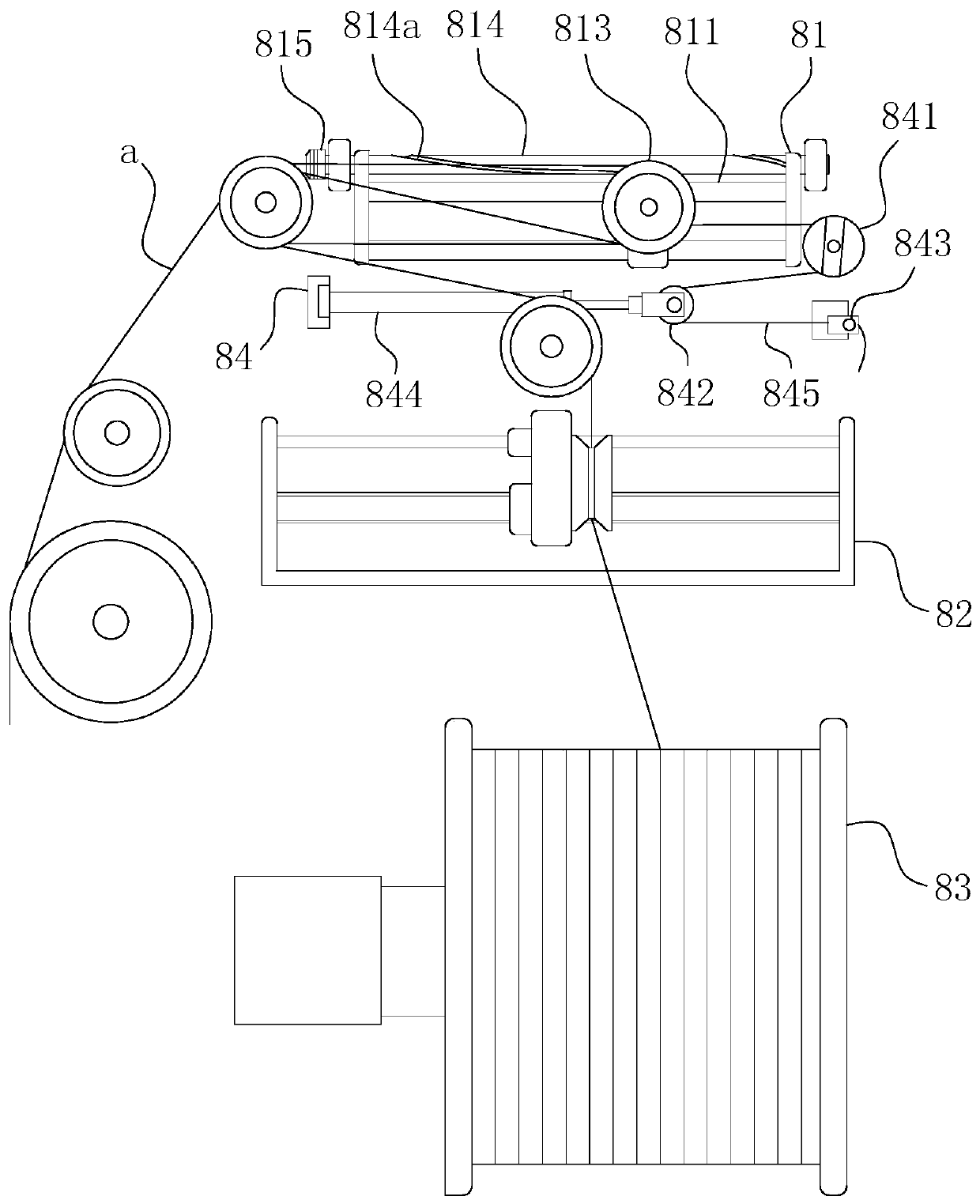

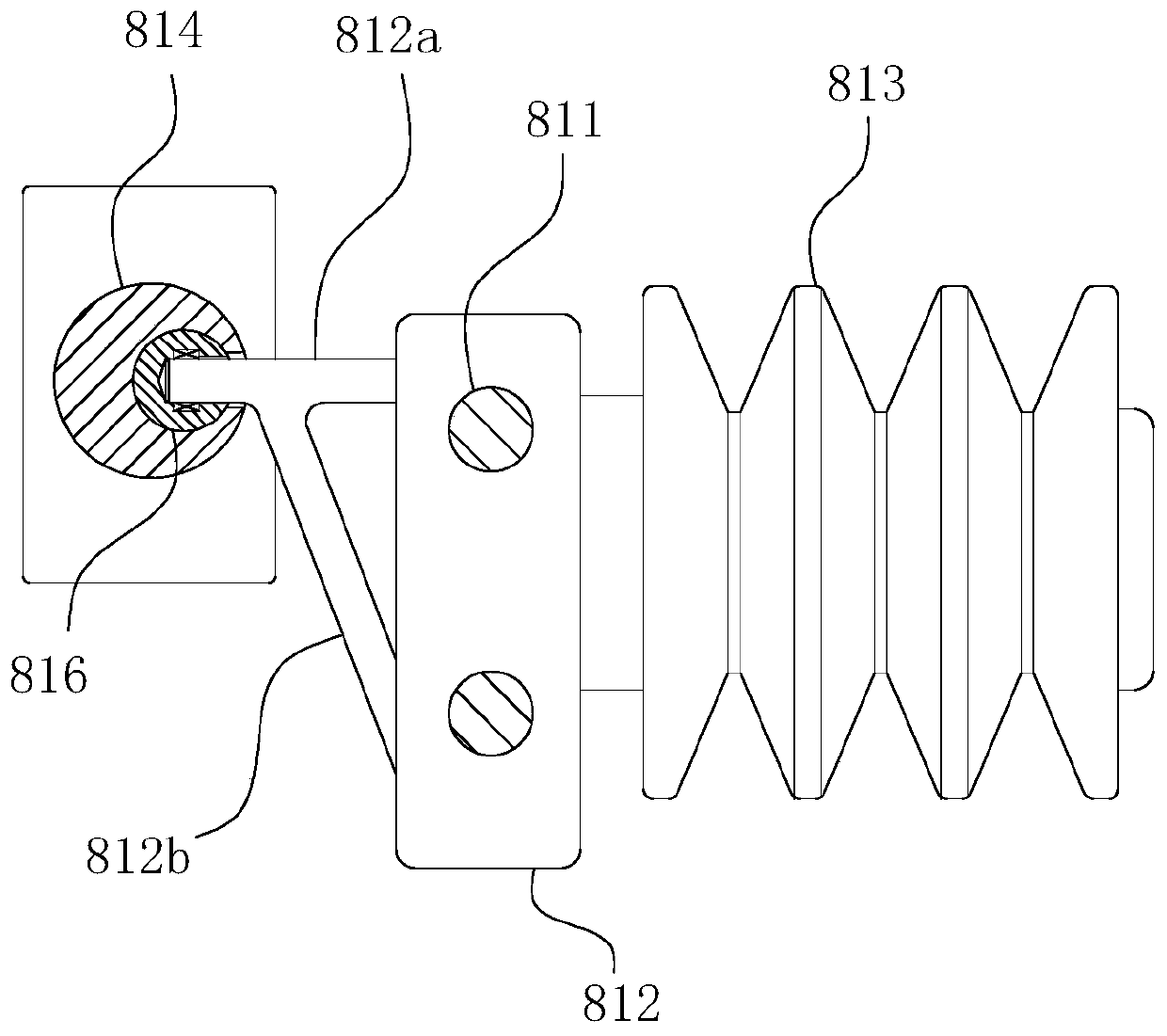

[0050] For ease of understanding, combined here Figure 1-4 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

[0051] The specific implementation process of the present invention can refer to figure 1 shown, including the following steps:

[0052] 1), blank preparation steps:

[0053] Prepare copper as the blank. The copper is industrial pure copper with a purity of more than 99.95%, and the required conductivity is not less than 98%. When preparing the copper, it is necessary to check whether its size is within the tolerance range, and ensure that the appearance of the copper is free from oxidation, Defects of burrs and cracks.

[0054] 2), drawing steps:

[0055] The copper material is stretched multiple times at a speed of 780-980m / min until the diameter is 6-8 times the diameter of the final wire, and the wire after large stretching is stretched multiple times at a speed of 1000-1100m / min to the final diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com