Wire drawing machine cable arrangement

A wire arrangement device and wire drawing machine technology, which is applied in the field of enameled wire production, can solve the problems of poor sensitivity and low service life, and achieve the effect of improving the degree of motion sensing, improving service life and ensuring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

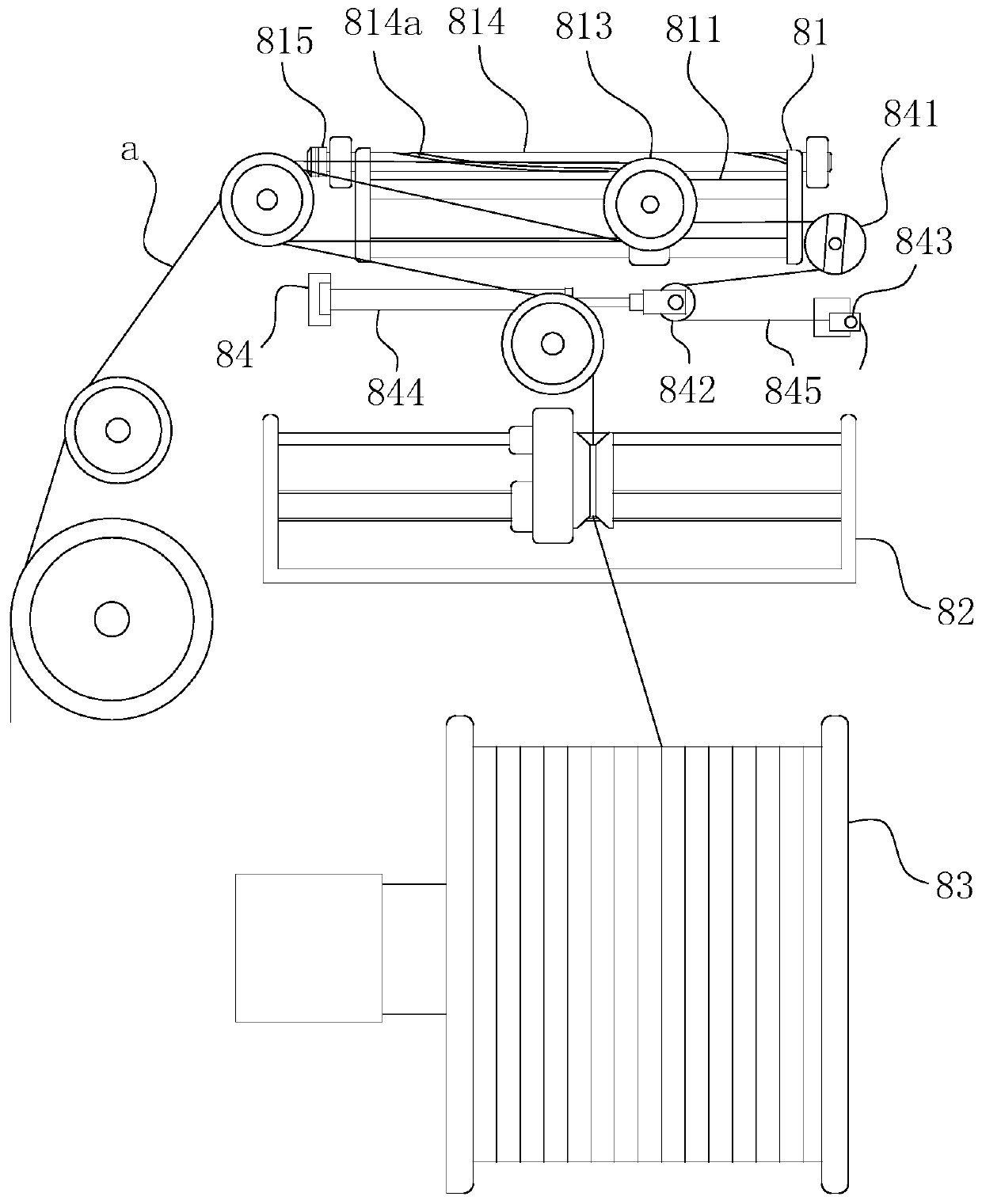

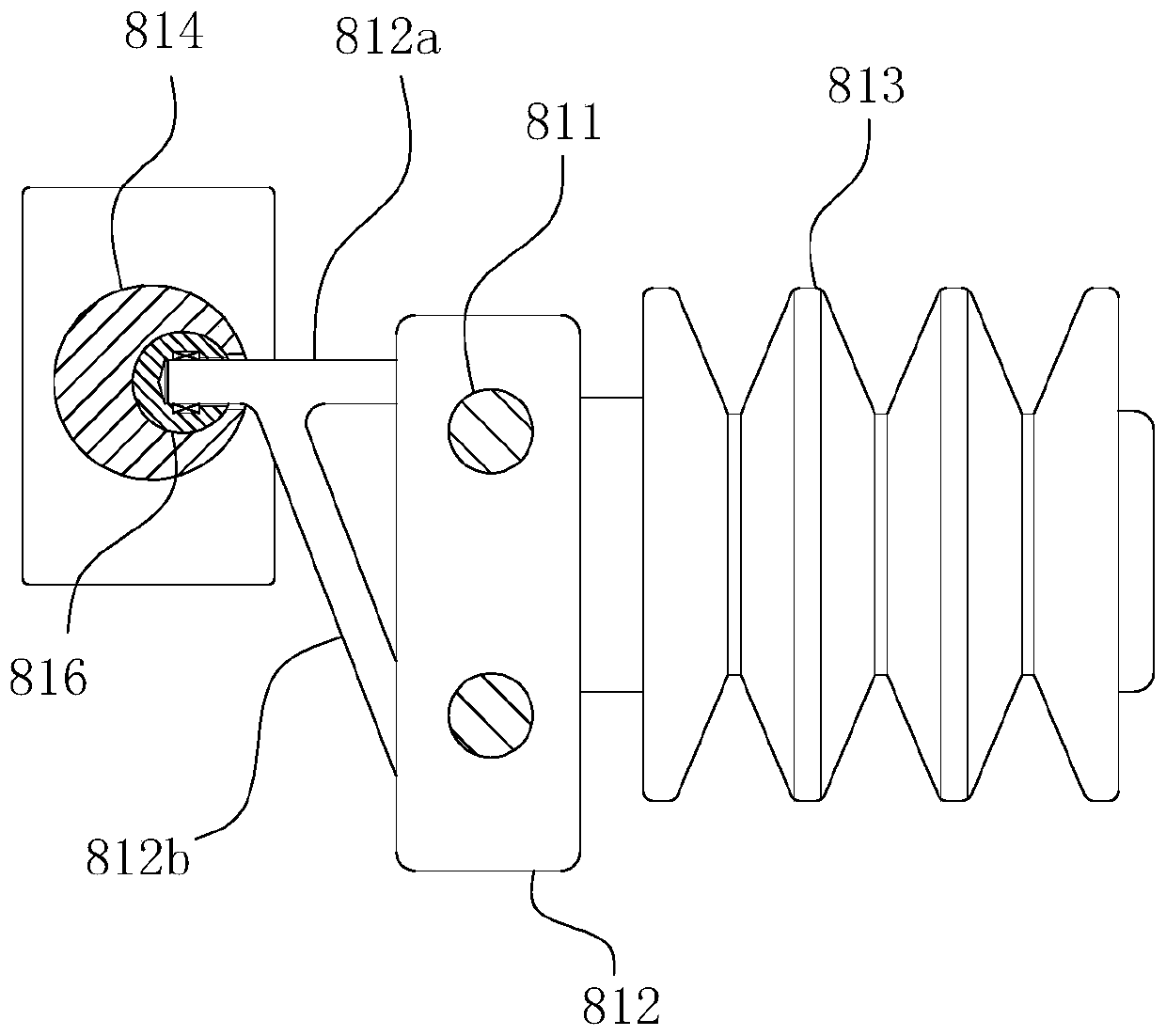

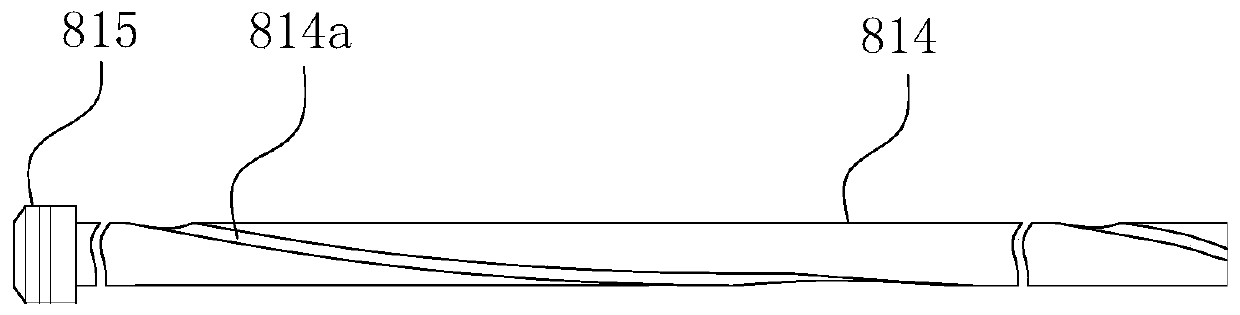

[0027] For ease of understanding, combined here Figure 1-3 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

[0028] The concrete implementation structure of the present invention can refer to Figure 1-3 As shown, metal wires a such as copper wires begin to enter the wire drawing machine wire arrangement device of the present invention through the guide of the steering wheel after the previous steps of unwinding, wire drawing, cleaning, annealing, cooling, painting, baking, and lubrication. . Such as figure 1 As shown, the wire arranging device of the wire drawing machine includes a tension control assembly 81 , a wire arranging assembly 82 and a wire take-up reel 83 sequentially arranged along the traveling direction of the wire a. The tension control assembly 81 is used for adaptive actions according to the take-up speed of the take-up reel 83, and then feeds back and controls the drive motor for driving the take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com