Display panel, manufacturing method thereof, and display device

A display panel and display device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of large parallel resistance between the cathode and auxiliary cathode, and the influence of the display effect of the display panel, so as to increase the contact area, Reduce the resistance and ensure the effect of display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

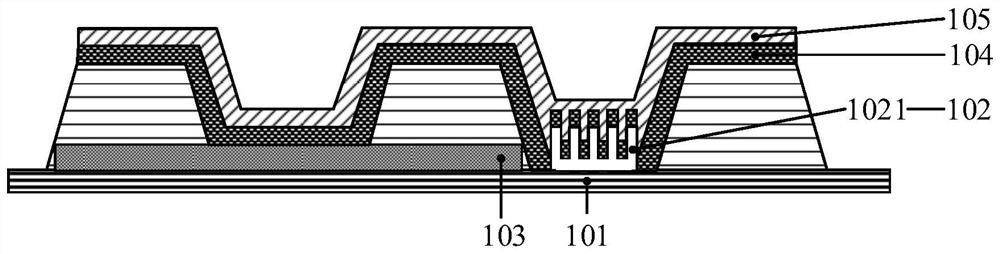

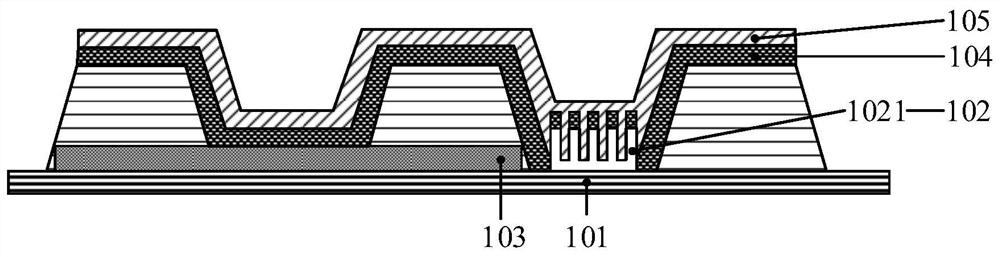

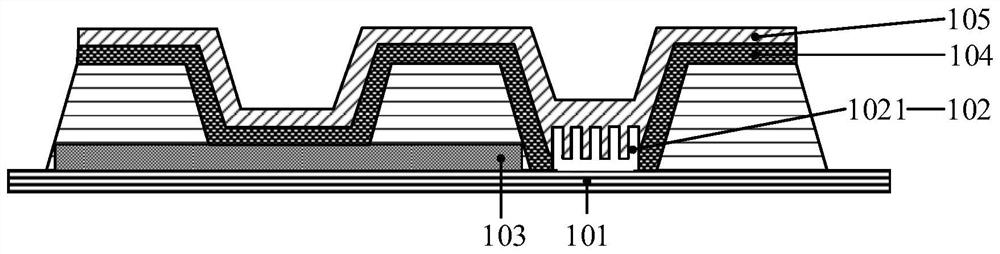

[0044] In recent years, due to the advantages of high color saturation and flexibility and deformability of flexible OLED display panels, their applications have become more and more widespread. As the screen of the display panel increases, the area of the pixel unit on the display panel increases accordingly. Moreover, the potential drop caused by the resistance of the cathode tends to be significant, resulting in a decrease in the voltage difference between the anode and the cathode, thereby causing a brightness gradient to appear in the display area of the display panel. For example, for a top-emission display panel, in order to ensure the transmittance of the electrode (cathode) on the light-emitting side, and because the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com