A GIS bus barrel mount multi-dimensional moving device

A technology of moving devices and busbar barrels, which is applied in the direction of lifting devices, switch devices, lifting frames, etc., can solve the problems of low installation and transportation efficiency, difficulty in meeting transportation and installation requirements, and easy danger caused by personal safety, and achieves simple structure and easy promotion , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

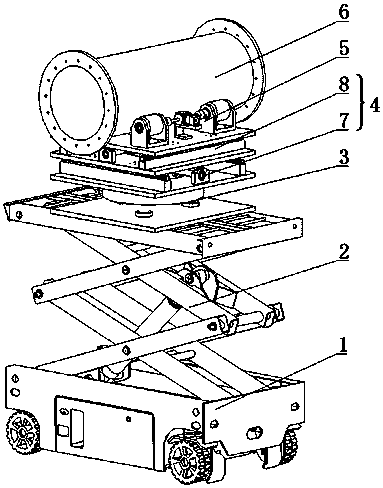

[0020] see figure 1 , in an embodiment of the present invention, a multi-dimensional motion device for installing a GIS bus barrel, including a chassis driving mechanism 1, a platform lifting mechanism 2, a rotation adjustment mechanism 3, a horizontal fine adjustment mechanism 4 and a bracket swing mechanism 5, and the chassis driving mechanism 1 The main function is to drive the whole device to walk and turn. It can be seen clearly from the figure that the chassis drive mechanism 1 has wheels. Of course, the way of walking and steering can be manual, and parts such as motors can also be installed in the chassis drive mechanism 1. To realize electric operation, a platform lifting mechanism 2 is installed on the chassis driving mechanism 1. Specifically, the platform lifting mechanism 2 is a scissor-type hydraulic lift. Of course, a screw lift can also be used, and no specific limitation is made here. , the platform lifting mechanism 2 is equipped with a rotation adjustment me...

Embodiment 2

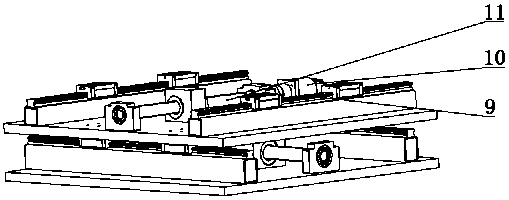

[0023] see figure 2 , the embodiment of the present invention is to further illustrate the horizontal fine adjustment mechanism 4. Specifically, the horizontal fine adjustment mechanism 4 includes a front and rear fine adjustment unit 7 and a left and right fine adjustment unit 8. Taking the left and right fine adjustment unit 8 as an example, the left and right fine adjustment units The fine-tuning unit 8 includes a sliding guide rail 9, a motor reducer-10 and a screw nut mechanism 11, the output end of the motor reducer-10 is connected to the screw nut mechanism 11, and the screw nut and the bracket in the screw nut mechanism 11 swing The mechanism 5 is connected, and the bracket swing mechanism 5 is also slidingly matched with the sliding guide rails 9 on both sides of the screw nut mechanism 11. When the motor reducer-10 outputs power, the bracket swing mechanism can be driven by the screw nut mechanism 11. 5 moves in the left and right direction to realize the front and ...

Embodiment 3

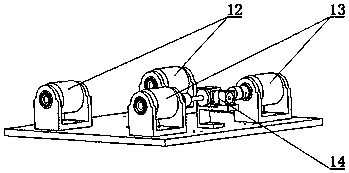

[0026] see image 3 , the embodiment of the present invention is to further illustrate the bracket swing mechanism 5. Specifically, the bracket swing mechanism 5 includes auxiliary rollers 12 and driving rollers 13 opposite to each other, and the busbar barrel 6 is placed on the auxiliary rollers 12 and driving rollers. Between 13, the auxiliary roller 12 and the active roller 13 jointly support the busbar barrel 6, wherein the active roller 13 is driven to rotate by the motor reducer 14, and the active roller 13 drives the busbar barrel 6 to rotate through friction, that is, completes the busbar Rotational fine-tuning of cylinder 6 axis direction.

[0027] Further, the number of the auxiliary rollers 12 and the driving rollers 13 is a pair.

[0028] It should be noted that in this technical solution, the chassis driving mechanism 1, the platform lifting mechanism 2, the rotation adjustment mechanism 3, the horizontal fine adjustment mechanism 4 and the bracket swing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com