A special cable laying tool

A special tool and cable laying technology, used in cable laying equipment, cable installation, cable installation devices, etc., can solve the problems of easily damaged cable safety, slow laying progress, physical exertion, etc., to prevent potential safety hazards and improve progress. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

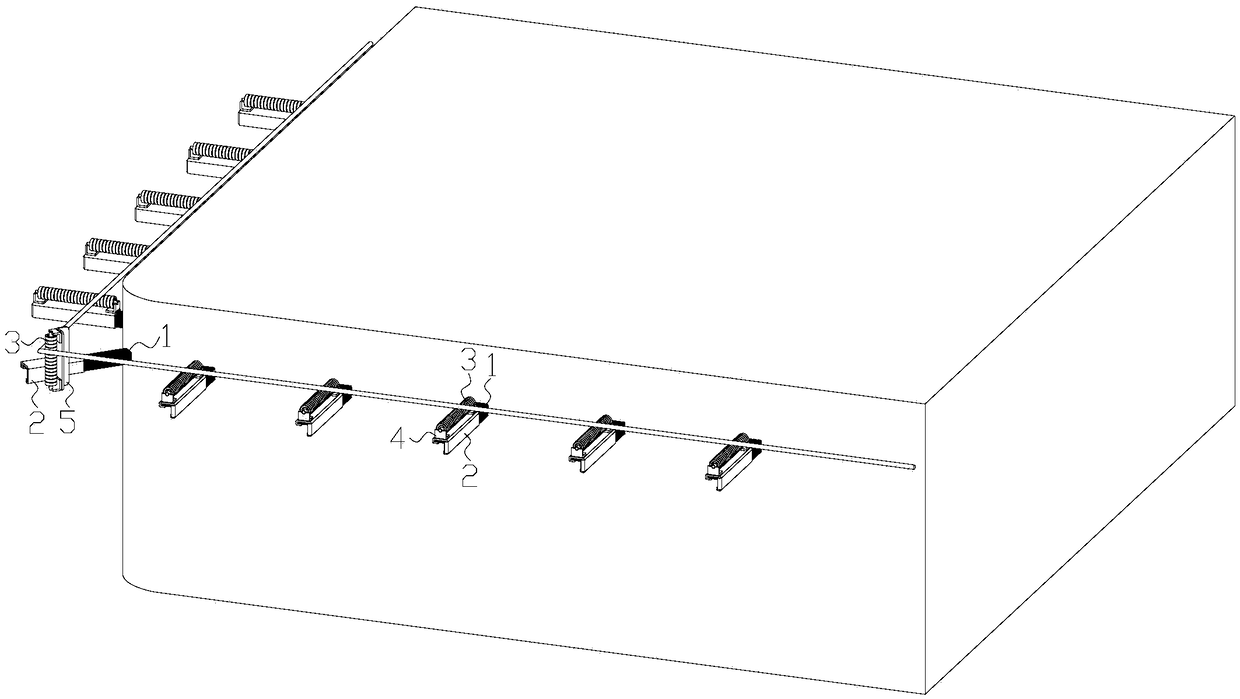

[0047] In practical applications, such as figure 1 As shown, the cable support 1 is usually installed on the side wall of the cable trench, and the cable support 1 is generally made of angle iron, or the shape of the cable support 1 is the same as that of the angle iron.

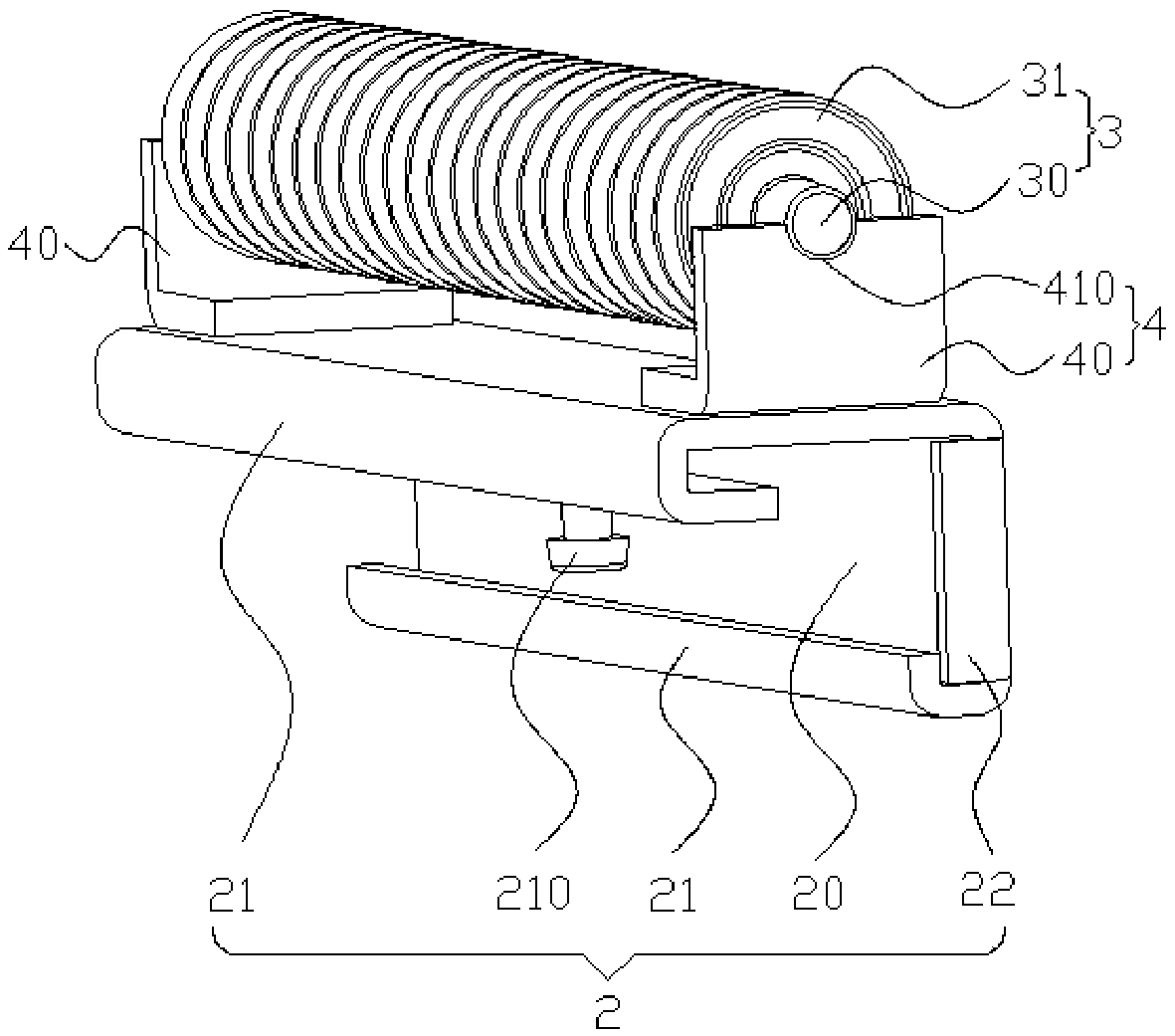

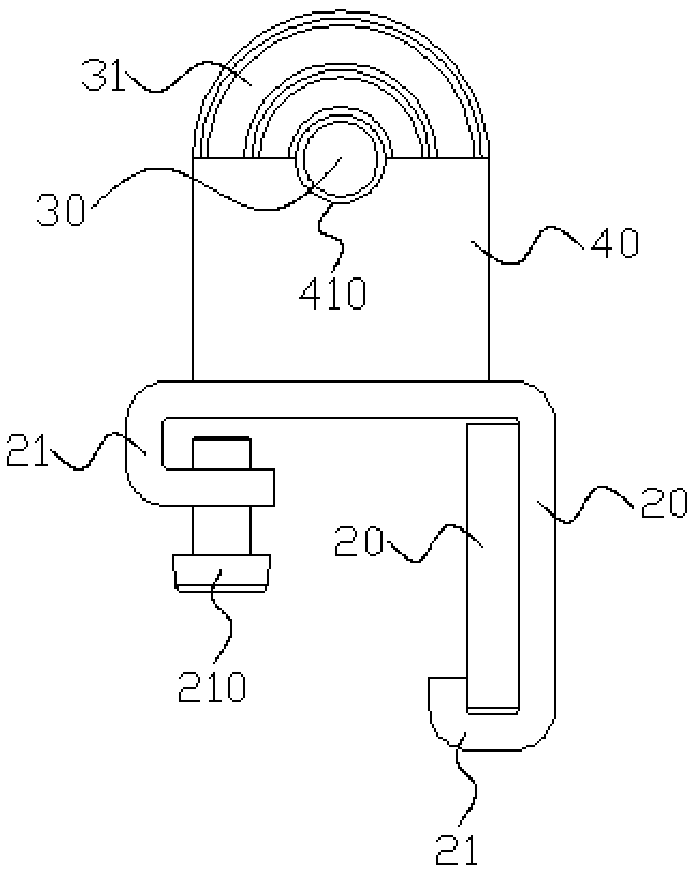

[0048] Such asfigure 1 As shown, the special cable laying tool provided in this embodiment includes a socket assembly 2 , a support assembly and a rotation assembly 3 . The socket assembly 2 is used for socketing on the cable support 1 , and the supporting assembly is installed on the socket assembly 2 .

[0049] Wherein, the rotating assembly 3 is installed on the supporting assembly, the rotating assembly 3 is used to support the cable, and the rotating assembly 3 can rotate on the supporting assembly.

[0050] In the process of laying cables, while installing the cable support 1 in the cable trench, the socket assembly 2 in the special cable laying tool provided by this embodiment can be socketed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com