Automatic cone electrostatic and metal filter tube net combined oil and dust removal system

An electrostatic composite and filter tube technology, applied in the field of electrostatic dust removal, can solve the problems of unsuitable oil dust and easy blockage of filter holes by oil dust particles, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

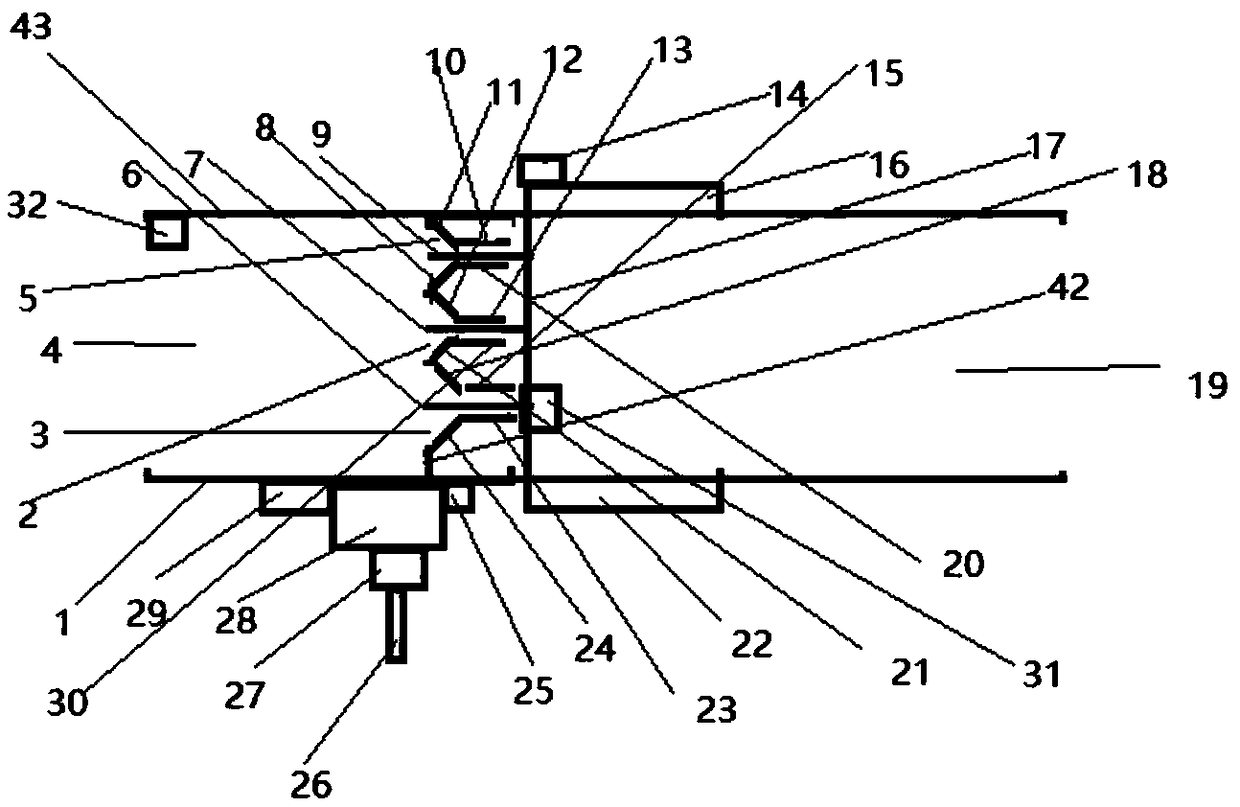

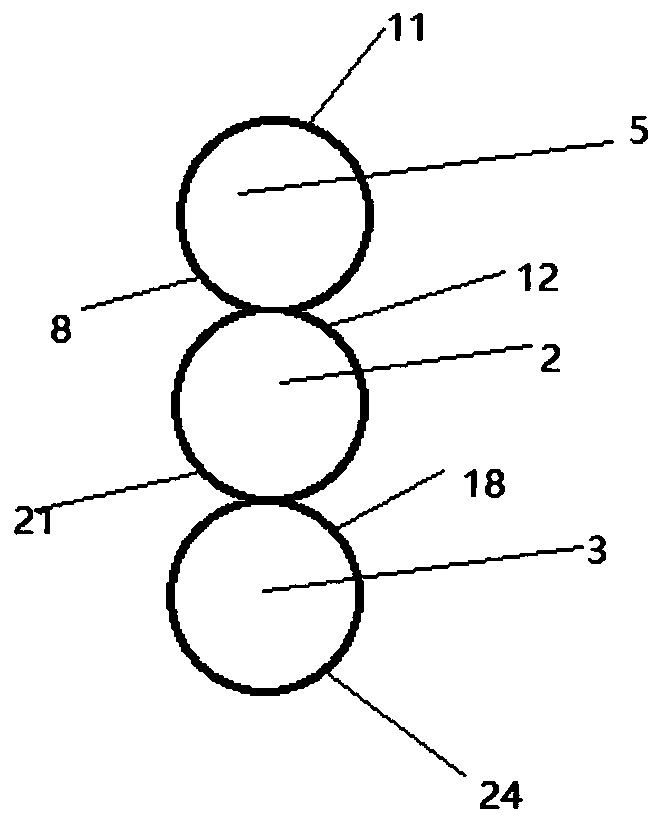

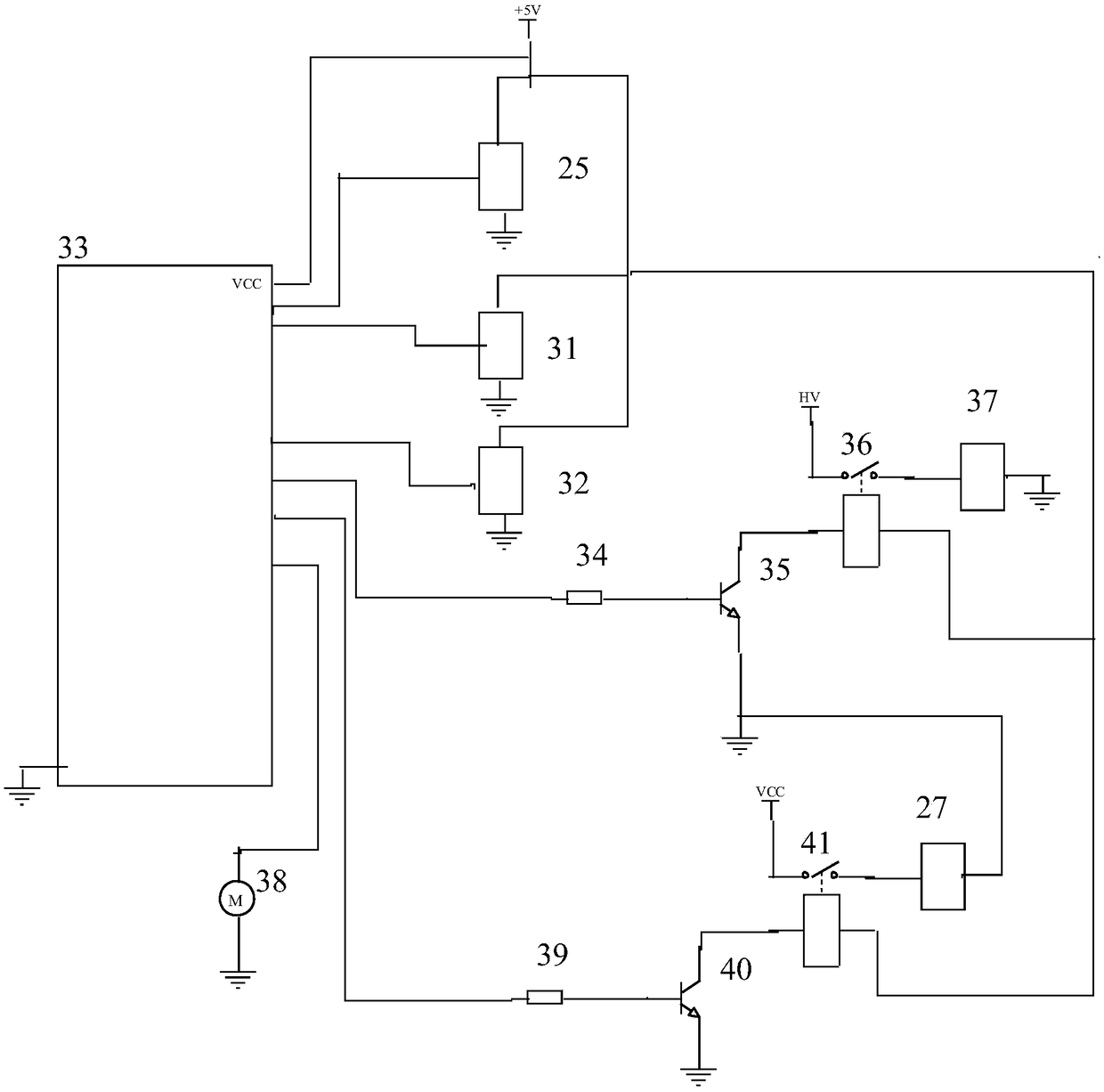

[0014] exist figure 1 Among them, the sliding rail 22 is connected with the lower wall 1 of the flue, the sliding rail 22 is below the lower wall 1 of the flue, the liquid level sensor 25 is connected with the lower wall 1 of the flue, and the liquid level sensor 25 is at the bottom of the lower wall 1 of the flue. Below, the oil storage tank 28 is connected with the lower wall 1 of the flue, the detergent tank 29 is connected with the lower wall 1 of the flue, the liquid level sensor 25 is connected with the oil storage tank 28, the solenoid valve 27 is connected with the oil storage tank 28, and the solenoid valve 27 Under the oil storage tank 28, the oil discharge pipe 26 is connected with the solenoid valve 27, the detergent tank 29 is connected with the oil storage tank 28, the particle size distribution sensor 32 is connected with the upper wall 43 of the flue, and the first upper half basin 11 is connected with the flue The upper wall 43 of the channel is connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com