Fully automatic bar processing turning machine

A fully automatic and lathe technology, applied in automatic/semi-automatic lathes, metal processing equipment, turning equipment, etc., can solve the problems of long preparation time and low efficiency of bar processing, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

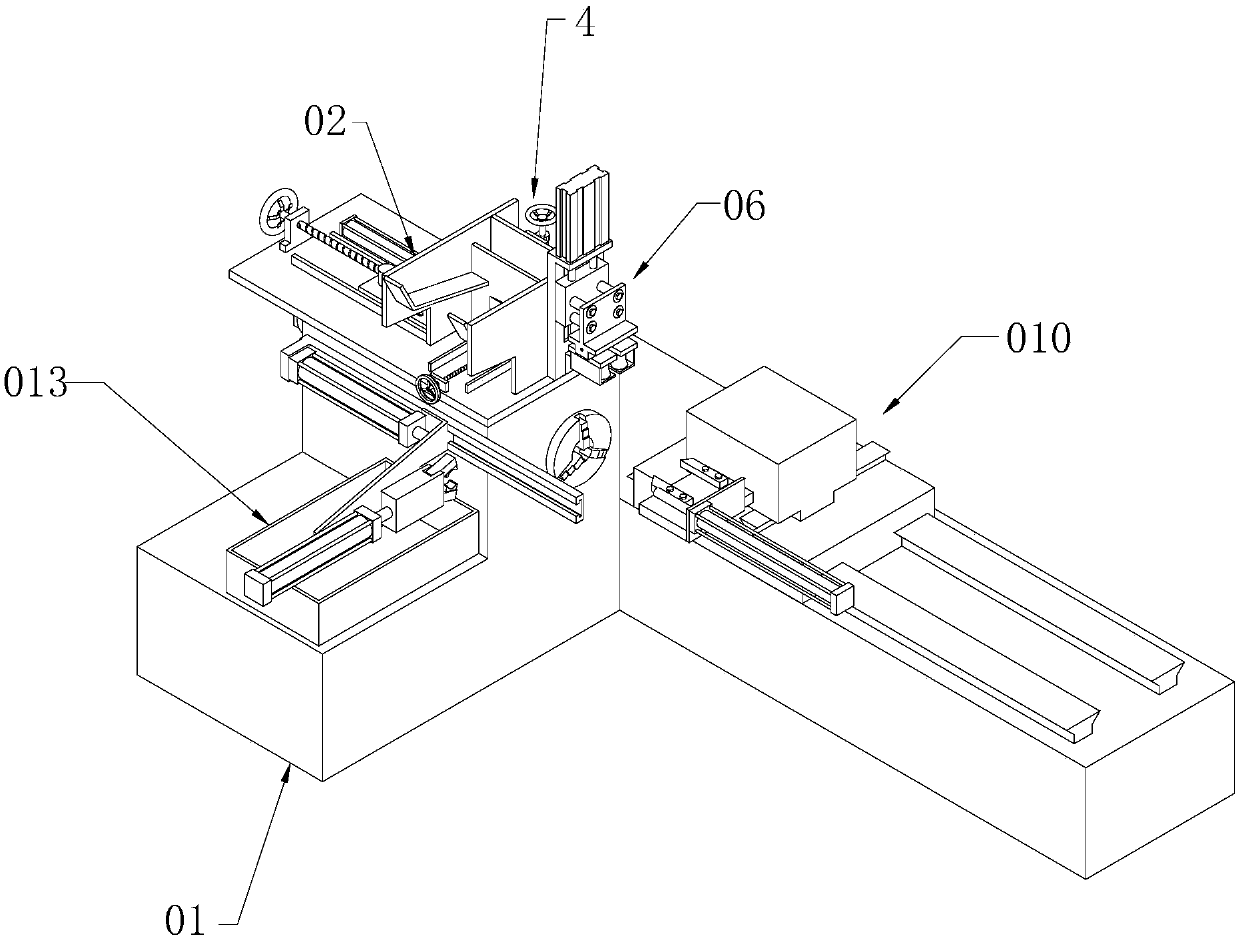

[0040] Such as figure 1 As shown, a fully automatic bar processing lathe includes a frame 01, a feeding unit 02, a loading unit 06, a processing unit 010 and an unloading unit 013 arranged on the frame 01 along the bar processing process, and the bar The materials are stored in the feeding unit 02, and the feeding unit 02 pushes the bars to the feeding unit 06 one by one. After the processing is completed, the bar is pushed again, and the unloading unit 013 takes out the processed side material from the processing unit 010 to complete the automated bar processing process.

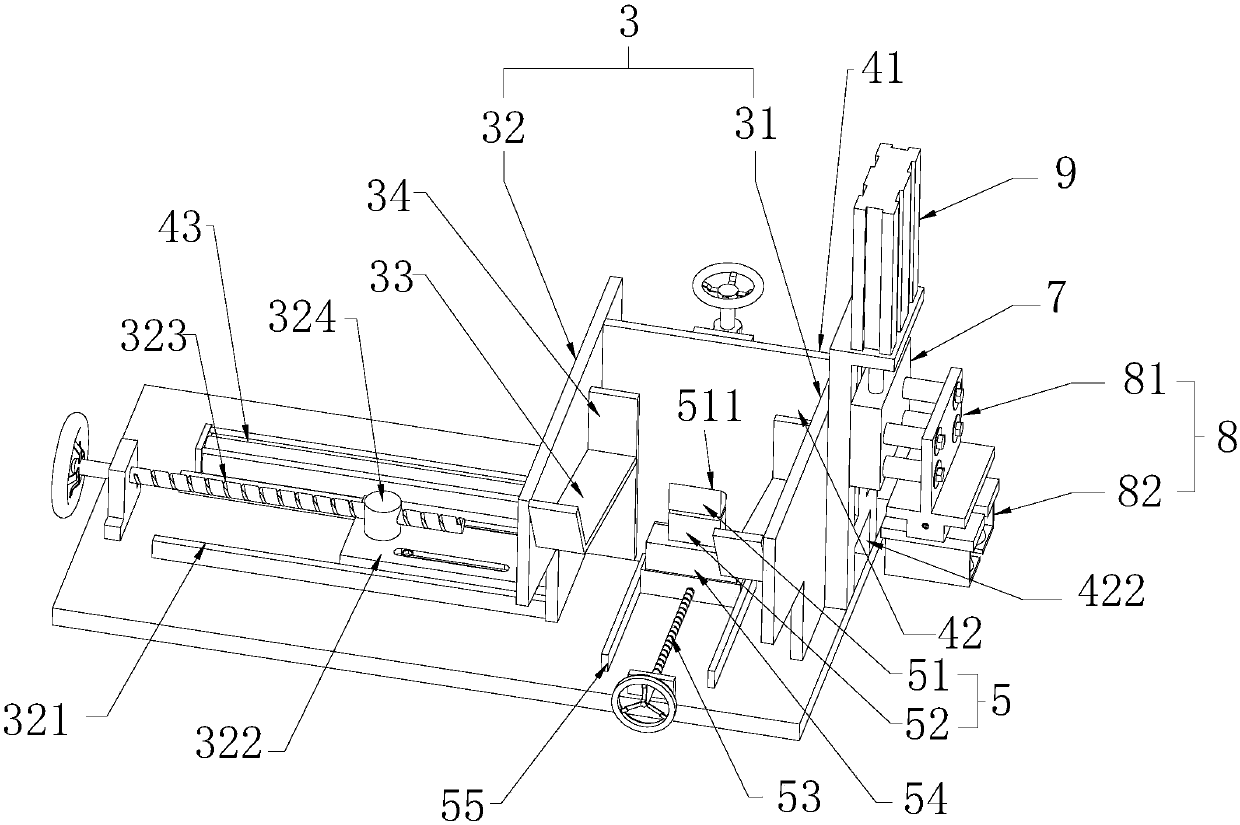

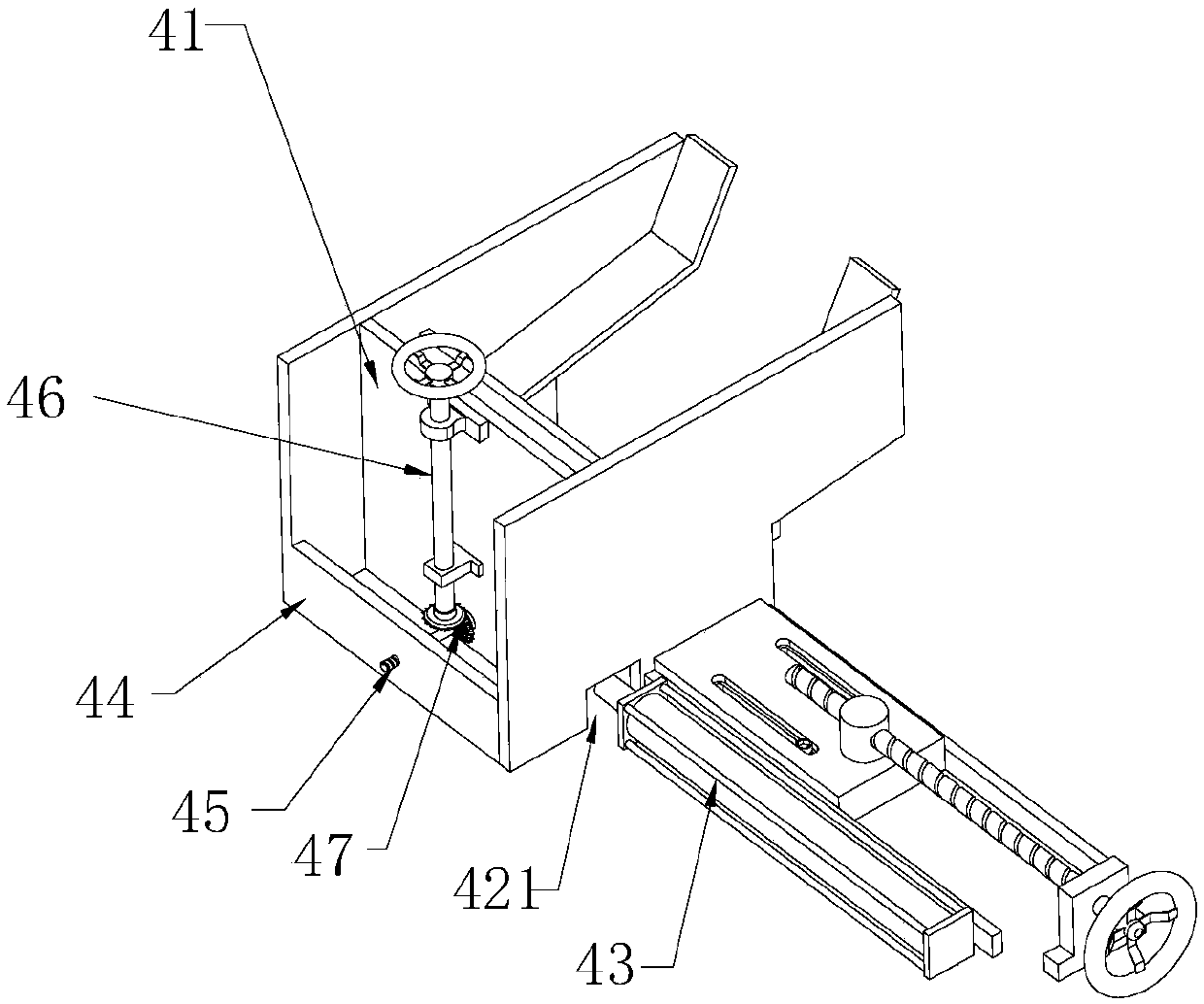

[0041] Such as figure 1 and figure 2 As shown, the feeding unit 02 includes a storage hopper 3, a discharge mechanism 4, and a material jacking mechanism. The storage hopper 3 includes a left end plate 32, a right end plate 31, and a support plate 33 arranged on the frame 01. Bars are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com