Corner wrapping mechanism for ceramic tile packaging

A technology for packaging and corner wrapping, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of limiting the wrapping angle, multi-suction, leakage and other problems, and achieves increased stability and changes in extrusion force. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

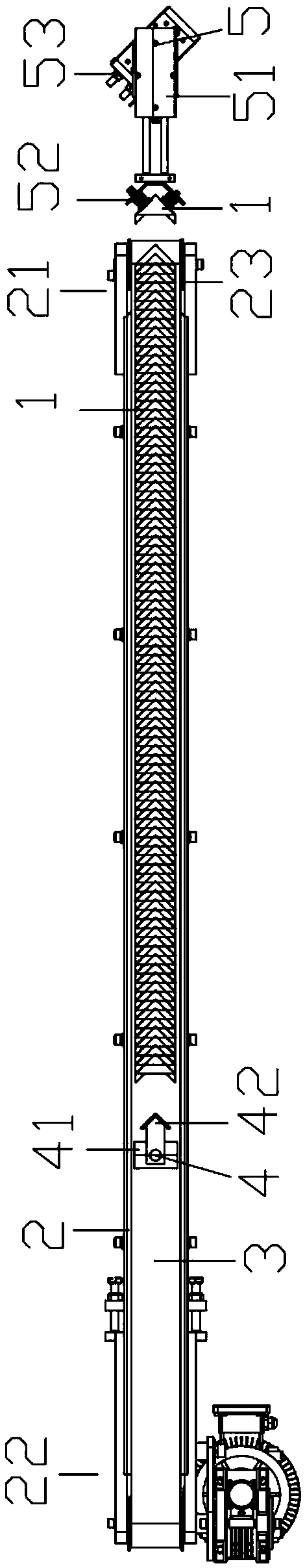

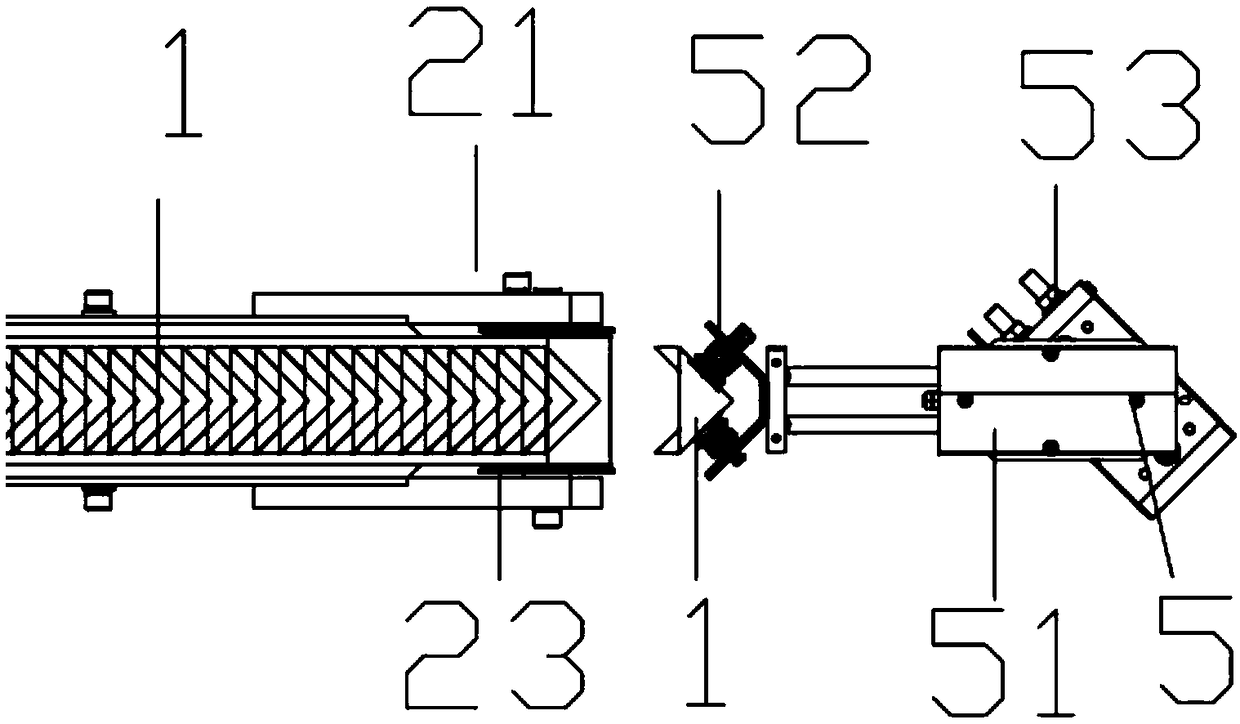

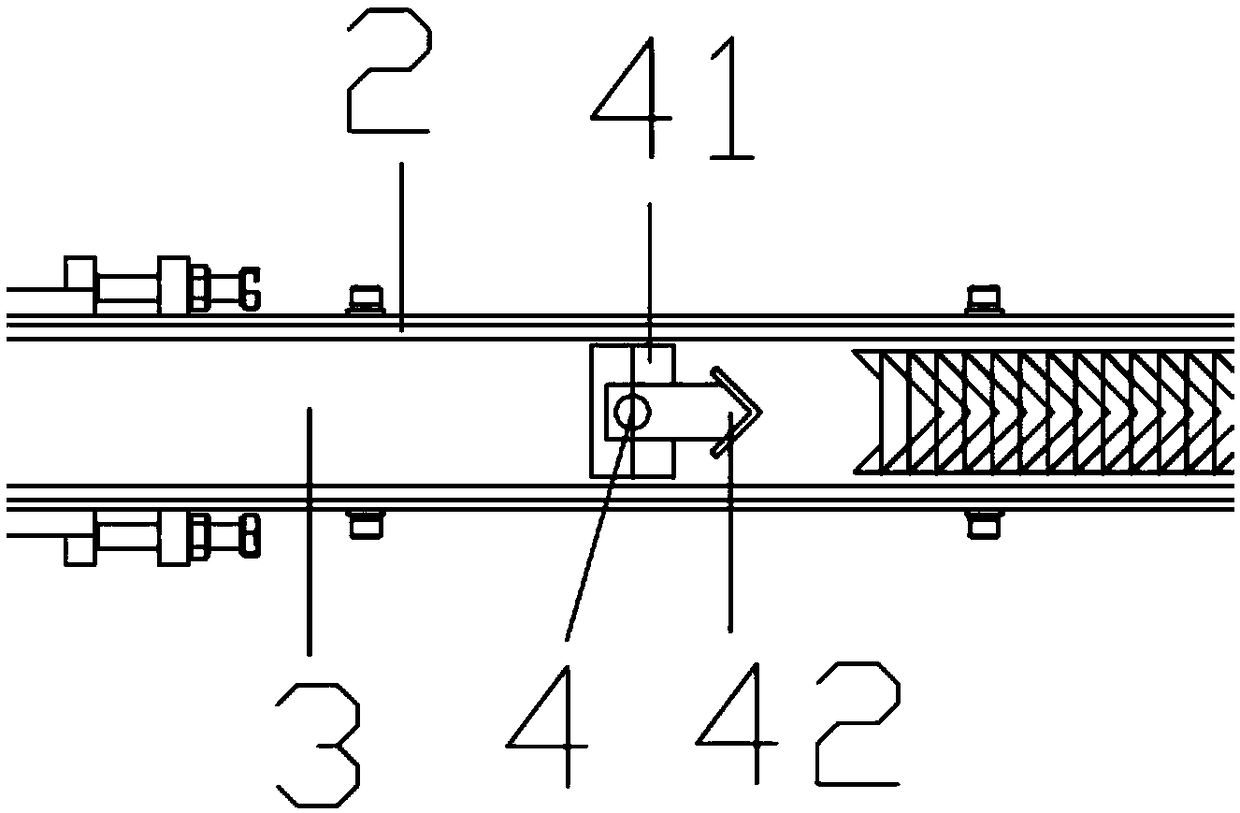

[0022] see Figure 1-Figure 5 As shown, the present invention discloses a corner-wrapping mechanism for tile packaging, including a corner-wrapping box 2 for placing the corner-wrapping box 1. The corner-wrapping box 2 is placed horizontally. 2, the conveying part 3 is provided with a pushing assembly 4 that moves synchronously with the conveying part 3 and is used to press and push the wrap angle 1.

[0023] The height of the corner wrapping box in the prior art limits the number of wrapping corners 1 to be added at one time. The corner wrapping box 2 of the present invention is placed horizontally, and the number of wrapping corners 1 to be added at one time is large, and the addition of wrapping corners 1 does not require the use of a working ladder. Easy to add.

[0024] In one embodiment, the corner wrapping box 2 takes the discharge end 21 as a fulcru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com