Parallel multiple main and branch horizontal well system

A horizontal well and horizontal technology, applied in drilling equipment, directional drilling, wellbore/well components, etc., can solve the problems of poor technical economy, high cost, low production, etc., and achieve the effect of overcoming the coal seam's easy collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will describe in detail with reference to the drawings in the embodiments of the present invention.

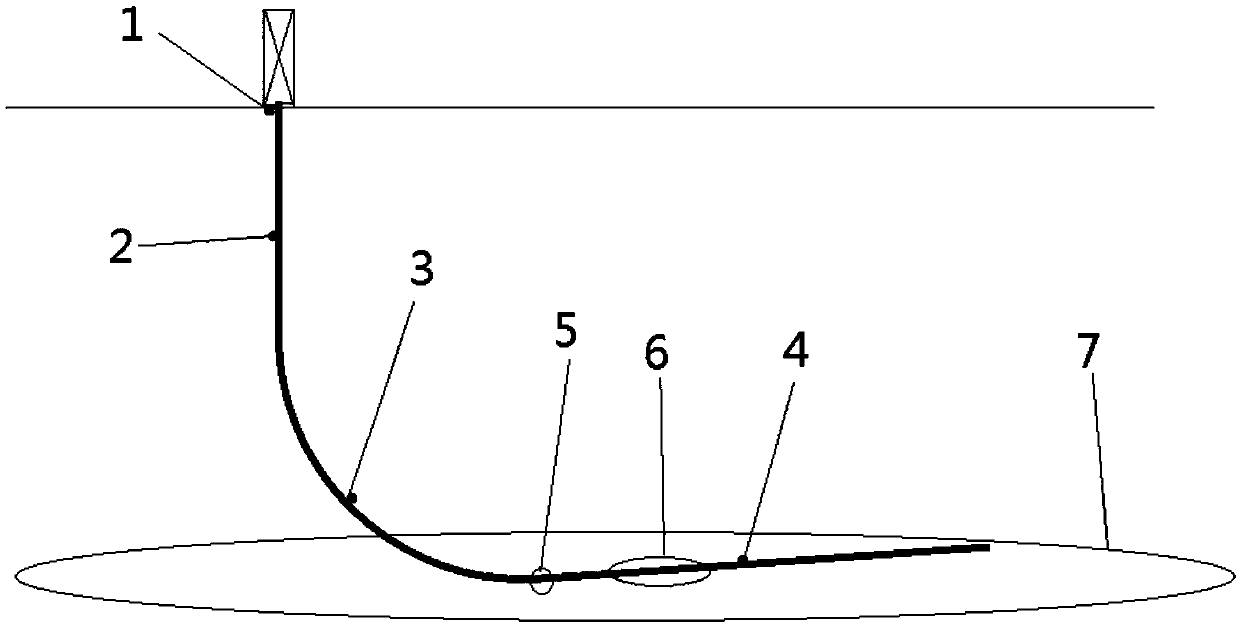

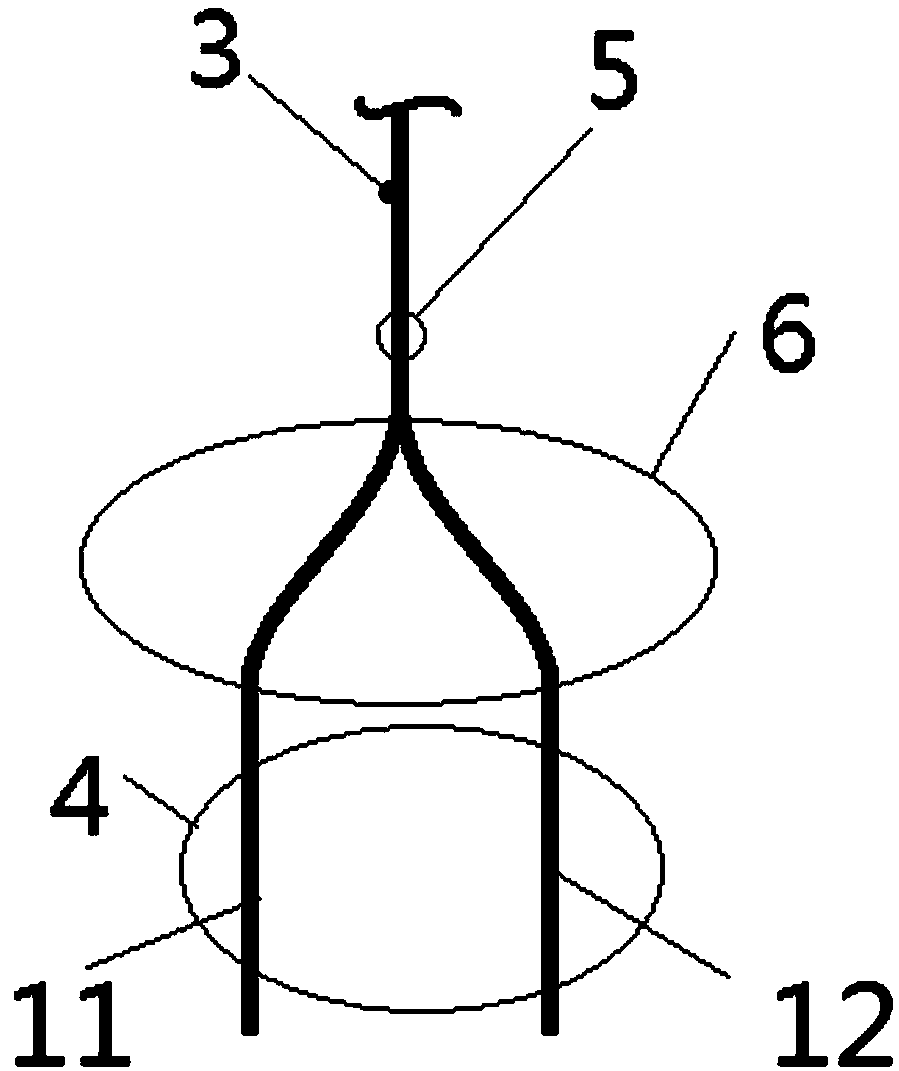

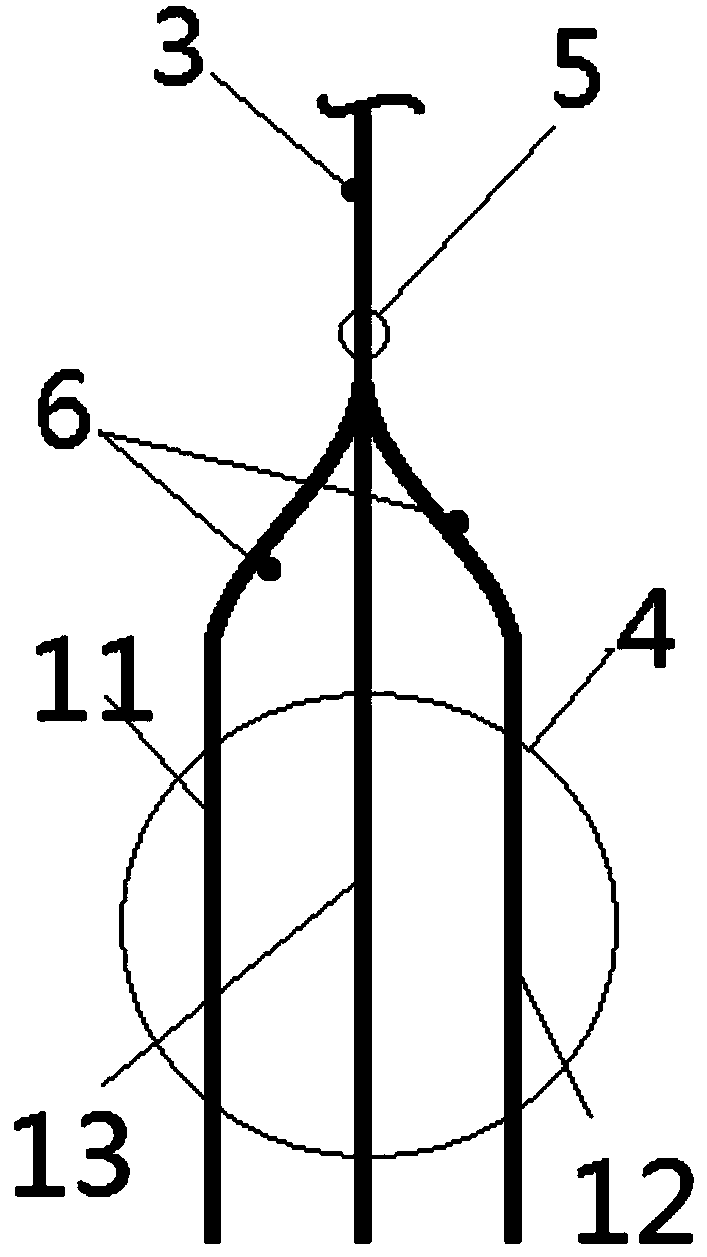

[0035] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a parallel multi-branch horizontal well system, characterized in that it includes: an upper straight section 2, which is a longitudinal channel extending vertically downward through the wellhead 1; an orientation section 3, which is an arc channel, and the head end of the directional section 3 communicates with the bottom end of the upper straight section 2, and the tail end of the directional section 3 cuts into the target formation 7 horizontally through the landing point 5; the horizontal extension section is set in the target formation 7 A plurality of main branch channels 4 are formed, and each main branch channel 4 communicates with the tail end of the orientation section 3 through the direction changing channel 6 respectively.

[0036] As a preferred embodiment one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com