A Method of Automatic Grouping of Rectangular Borders

A frame and rectangle technology, applied in the field of automatic frame grouping of rectangular frames, can solve the problems of high labor intensity of staff, affecting the production efficiency of doors and windows, increasing labor costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below through specific examples.

[0044] A method for automatically forming a frame for a rectangular frame, comprising the following steps implemented in sequence:

[0045] S1. Carry out the process of positioning and conveying the long frame and the short frame, and the long frame and the short frame are conveyed synchronously;

[0046] In the above-mentioned short frame positioning and conveying process, there are frame positioning process and corner code extrusion process. downstream;

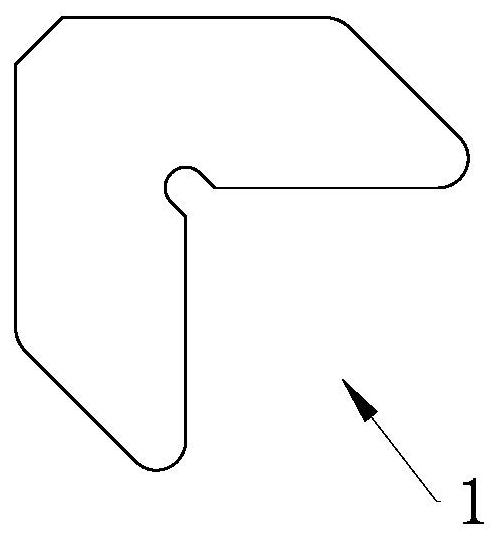

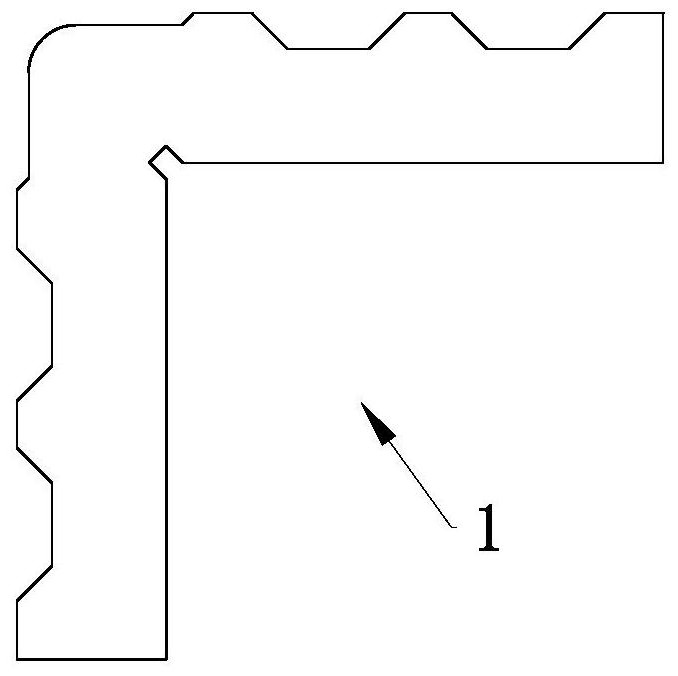

[0047] S2. Carry out the corner code feeding and splicing process of inserting the corner code 1 on one of the long frame or the short frame, and complete the insertion of the corner code 1 during the transportation of the long frame or the short frame. As a preference, the corner code 1 Code 1 is inserted on the short frame;

[0048] And before the corner code loading and splicing process, the short frame jacking and posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com