Telescopic mechanism for hand-held weeding machine

A telescopic mechanism and a weeding machine technology, applied in the field of weeding machines, can solve the problem that the length of the hand-held part of the hand-held weeding machine is not adjustable, and achieve the effects of convenient expansion, labor saving, and labor intensity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

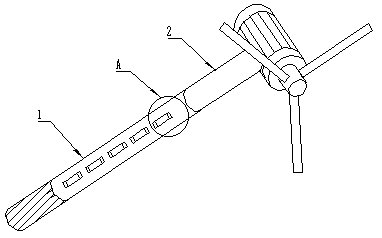

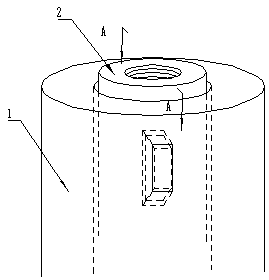

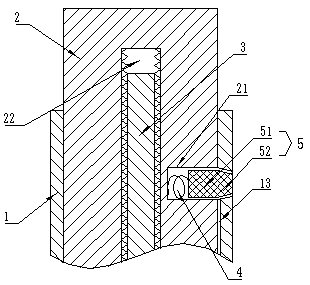

[0028] combined with Figure 1-6 As shown, a telescopic mechanism of a hand-held weeder includes a hand-held rod 1 and a moving rod 2 on which the weeder is installed. The motor of the switch, the rotating shaft of the motor is connected with a screw 3, the screw 3 is connected with the moving rod 2 and the axis line of the screw 3 is parallel to the long axis of the moving rod 2.

[0029] The present invention is a new telescoping mechanism of a hand-held weeder. A moving rod 2 is set inside a hand-held rod 1 to control the relative movement of the moving rod 2 and the hand-held rod 1 to realize telescoping. A motor is installed in the hand-held rod 1 and connected to Power supply and switch, through the switch to control the forward and reverse rotation of the motor, the screw rod 3 connected to the motor is driven to rotate, and the screw rod 3 is connected to the moving rod 2, and the rotation of the screw rod 3 makes the position of the moving rod 2 and the hand-held rod ...

Embodiment 2

[0031] This embodiment is based on the above embodiments, combined with the attached Figure 2-4 As shown, further defined, the side wall of the moving rod 2 is provided with a mounting groove 21, the bottom of the mounting groove 21 is installed with a spring 4, and the end of the spring 4 away from the bottom of the mounting groove 21 is connected to the A key 5 , the side wall of the handle bar 1 is provided with an A groove 11 matching with the A key 5 . Wherein the connection of installation groove 21, spring 4 and A key 5 makes the movement of moving rod 2 partially limited, thereby can move according to the direction required, and A key 5 can compress spring 4 and enter the inside of installation groove 21 to generate in moving rod 2 It is not affected by exercise.

[0032] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0034] This embodiment is based on the above embodiments, combined with the attached figure 2 As shown, it is further defined that the A key 5 includes an A part 52 and a B part 51 connected to the spring 4, and the surfaces of the A part 52 close to the motor and away from the motor are both wedge-shaped surfaces and the two wedge-shaped surfaces are "eight" The "eight"-shaped bottoms of the two wedge-shaped surfaces are connected to the B part 51, and the B part 51 is installed in the installation groove 21. Wherein, the wedge-shaped surface of "eight" shape is set, so that the moving rod 2 can be stretched or retracted without locking when moving in the required direction.

[0035] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com