Injection molding machine for winding pipe connectors

A technology for injection molding machines and winding tubes, which is applied in the field of injection molding machines for winding pipe joints. It can solve the problems of complex structure and control methods, poor use flexibility, and long glue feeding time, so as to achieve shortened glue injection time, flexible use, and glue injection. The effect of small material storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below are specific embodiments of the present invention and in conjunction with accompanying drawing, technical scheme of the present invention is described further, but the present invention is not limited to these embodiments.

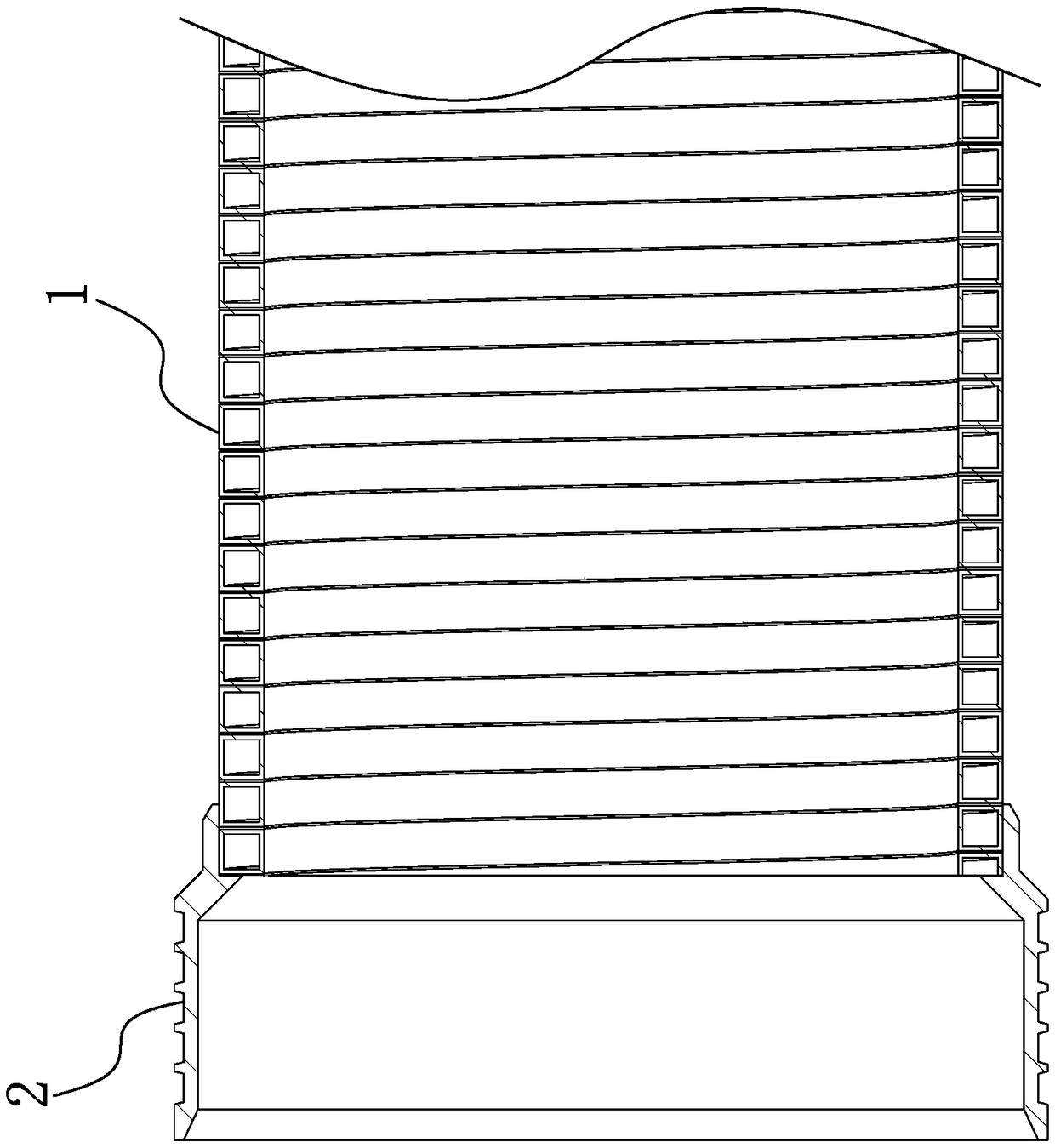

[0057] figure 1 It is the connection structure between the plastic pipe 1 and the joint 2. The plastic pipe 1 is a circular corrugated pipe. The plastic pipe 1 is formed at one time by the pipe forming equipment. When making the joint 2, connect one end of the plastic pipe 1 to the mold of the injection molding machine. In the mold 70, the raw material is injected into the mold 70, and the raw material is formed into a joint 2 in the mold 70 and then integrated with the plastic pipe 1.

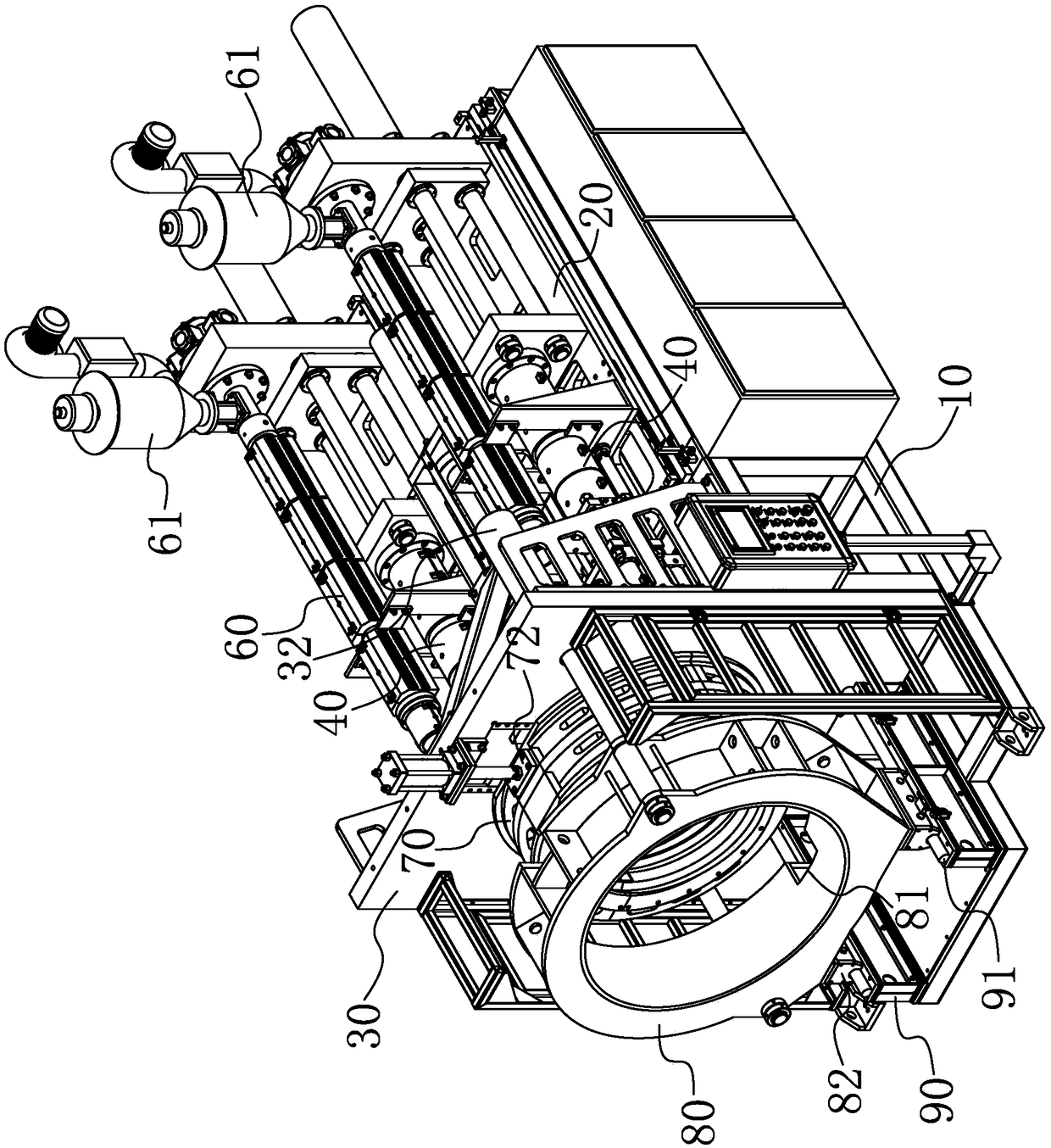

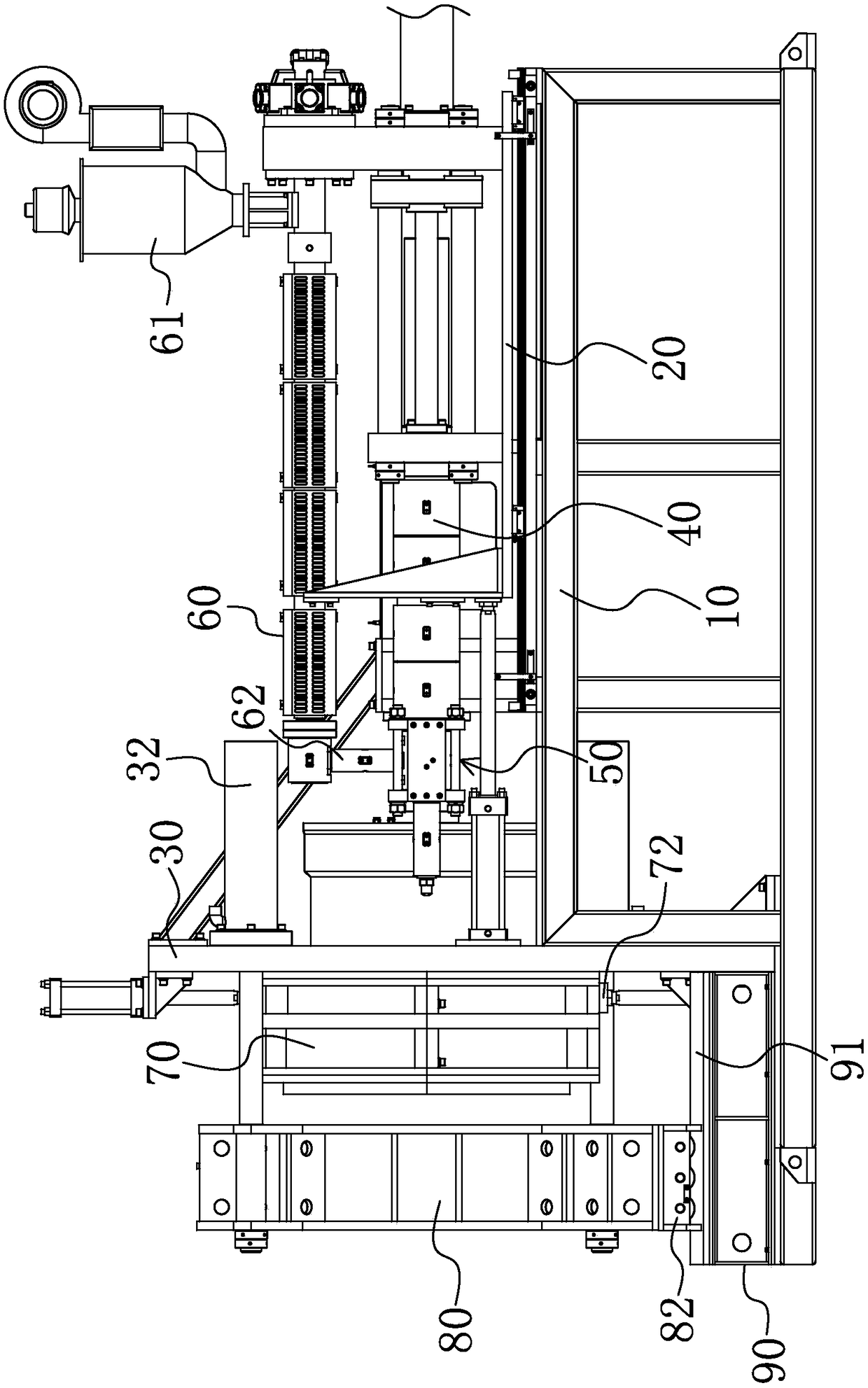

[0058] Such as figure 2 , image 3 , Figure 8 As shown, the present invention is an injection molding machine for winding pipe joints, which is used for molding injection molding of plastic pipes 1 and joints 2, including a fixed frame 10, a moving seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com