Flexible pouch conveying and boxing system

A soft bag packing and bag packing technology, which is applied in the directions of packaging, packaging protection, transportation and packaging, can solve the problems of not fully automated production, low production efficiency and high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

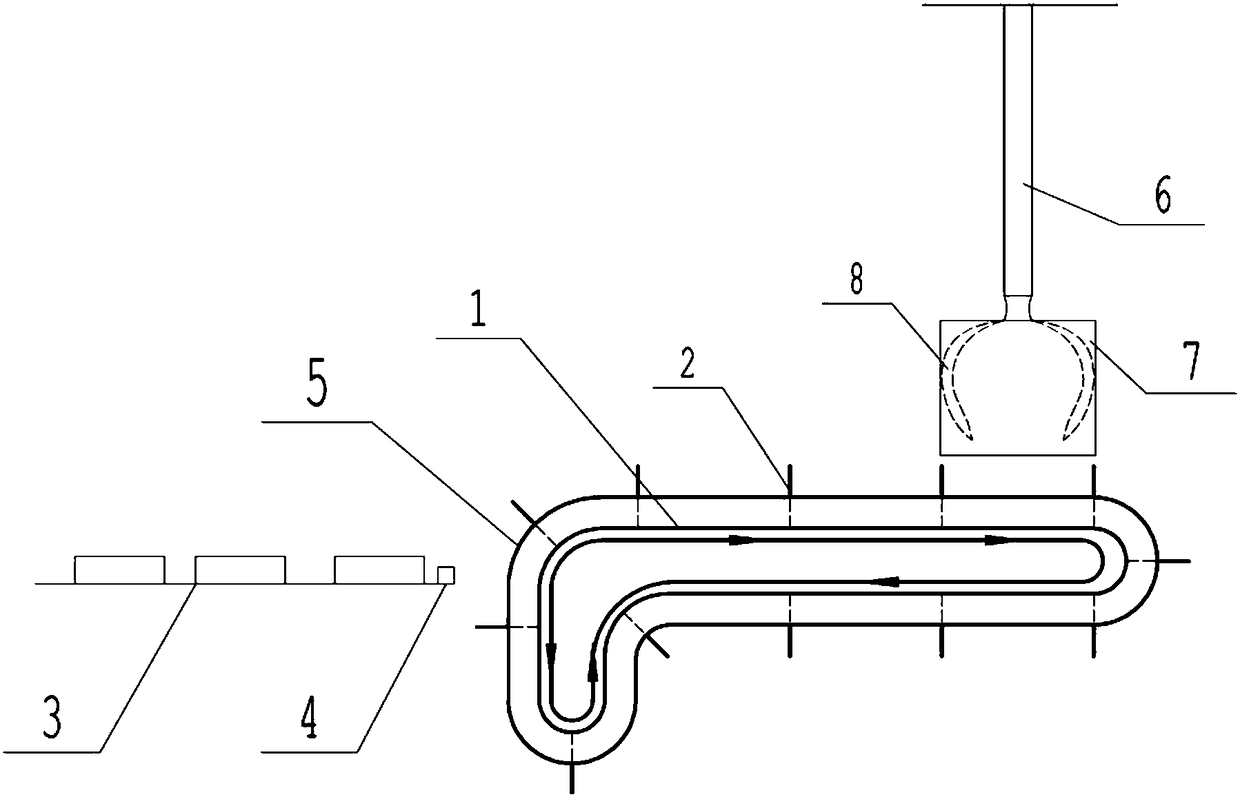

[0017] Such as figure 1 The soft bag conveying and boxing system shown includes a finished product conveyor belt, a soft bag boxing conveyor belt, a manipulator system and a boxing positioning device. The finished product conveyor belt is at the front end of the soft bag packing conveyor belt, and the position between the manipulator system and the soft bag packing conveyor belt is set according to the packing position. The robotic arm system includes a mechanical gripper. The mechanical gripper of the manipulator system is provided with manipulator baffles corresponding to the sides of both sides of the conveyor belt, and the length of the manipulator baffles is adapted to the distance between adjacent partitions.

[0018] The end of the conveyor belt for finished products is provided with a counting sensor, which can accurately count the soft bags sent to the conveyor belt. Several partitions are equidistantly arranged on the soft bag boxing conveyor belt, baffles are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com