Non-dusting cement feed hopper and feeding method thereof

A feeding hopper and cement technology, applied in the construction field, can solve problems such as ineffective application, and achieve the effect of improving the construction environment, comfortable and safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

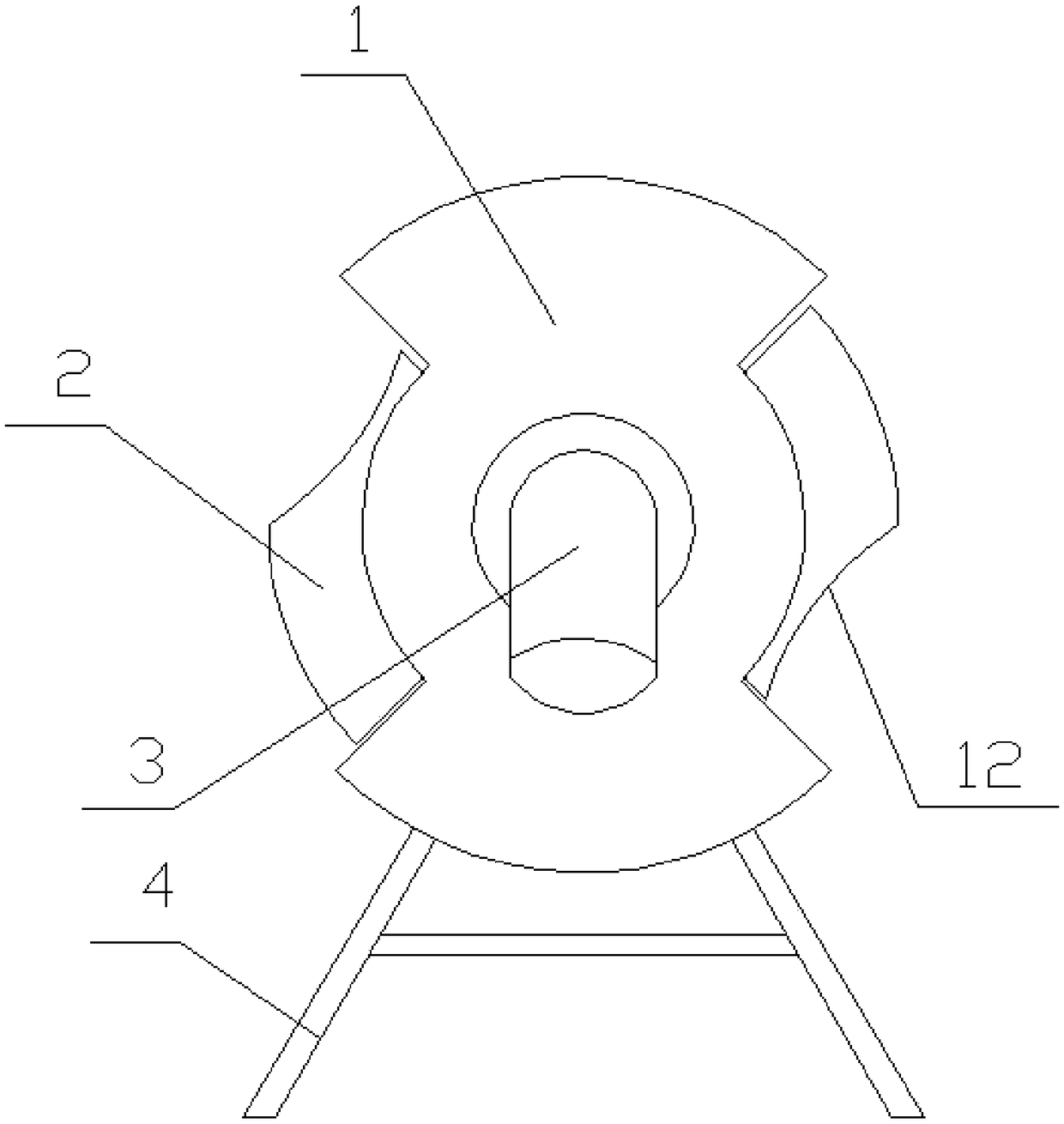

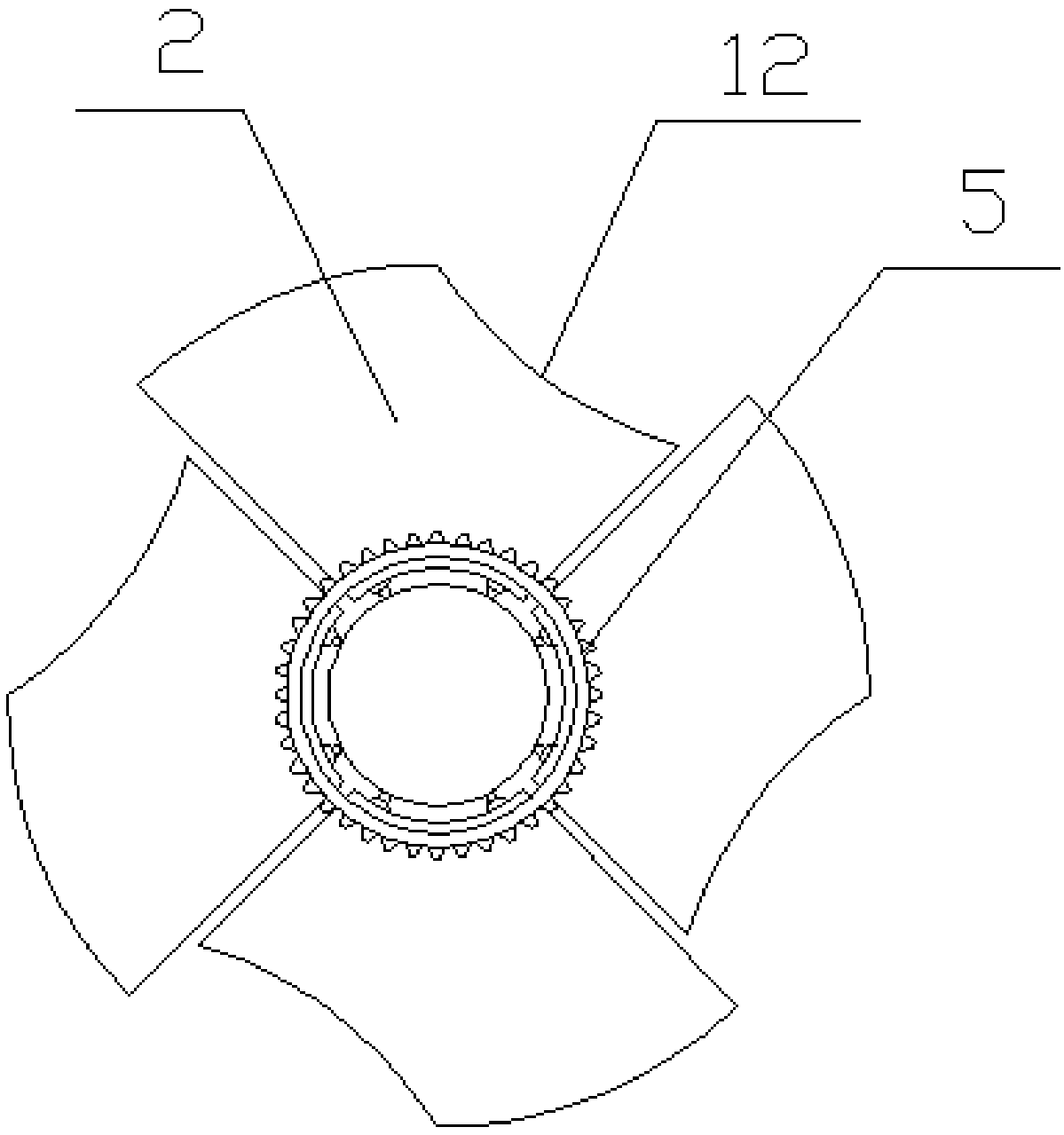

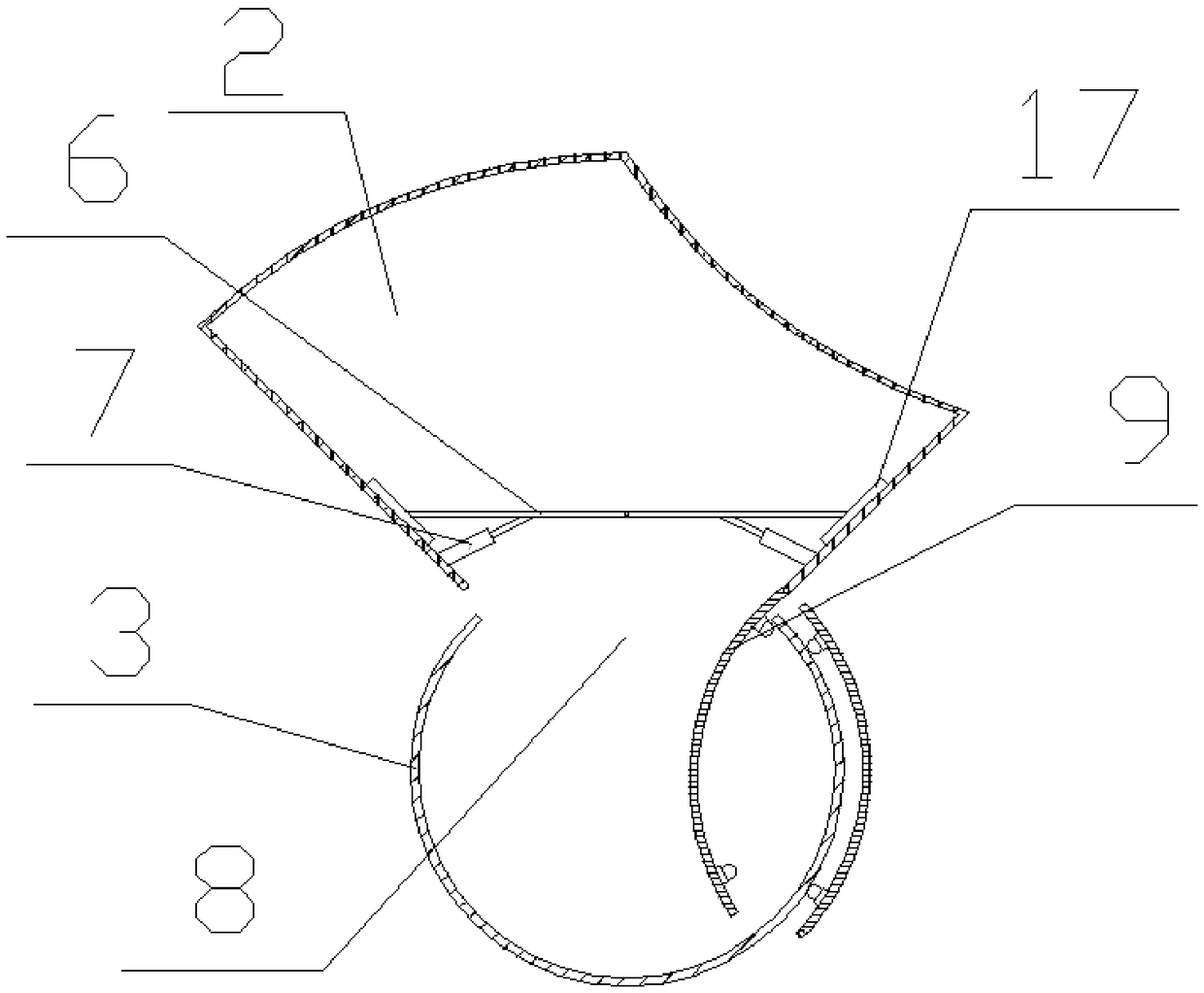

[0034] Such as Figure 1 to Figure 8 As shown, a non-dusting cement feed hopper includes a casing assembly, a feed hopper assembly and a transmission assembly, the casing assembly includes a casing 1, and the casing 1 is a hollow cylinder with left and right sides There are fan-shaped openings, the left fan-shaped opening is used for feeding, and the right fan-shaped opening is used for discharging. The feeding hopper assembly includes a feeding hopper 2, a rotating shaft 5 and a feeding pipe 3, and the feeding hopper 2 passes through the rotating shaft. 5 The rotation is arranged inside the casing 1, the feed pipe 3 is arranged at the center of the casing 1, one end of which is sleeved inside the rotating shaft 5, and the other end is arranged outside the casing 1, and the feed pipe 3 is used for In bringing the raw materials in the feed hopper 2 into the device, the feed hopper 2 has four, which are evenly arranged on the rotating shaft 5, and the feed hopper 2 is provided w...

Embodiment 2

[0047] Such as Figure 1 to Figure 7 , Figure 9 to Figure 11As shown, a non-dusting cement feed hopper includes a casing assembly, a feed hopper assembly and a transmission assembly, the casing assembly includes a casing 1, and the casing 1 is a hollow cylinder with left and right sides There are fan-shaped openings, the left fan-shaped opening is used for feeding, and the right fan-shaped opening is used for discharging. The feeding hopper assembly includes a feeding hopper 2, a rotating shaft 5 and a feeding pipe 3, and the feeding hopper 2 passes through the rotating shaft. 5 The rotation is arranged inside the casing 1, the feed pipe 3 is arranged at the center of the casing 1, one end of which is sleeved inside the rotating shaft 5, and the other end is arranged outside the casing 1, and the feed pipe 3 is used for In bringing the raw materials in the feed hopper 2 into the device, the feed hopper 2 has four, which are evenly arranged on the rotating shaft 5, and the fe...

Embodiment 3

[0060] Such as Figure 1 to Figure 11 As shown, a non-dusting cement feed hopper includes a casing assembly, a feed hopper assembly and a transmission assembly, the casing assembly includes a casing 1, and the casing 1 is a hollow cylinder with left and right sides There are fan-shaped openings, the left fan-shaped opening is used for feeding, and the right fan-shaped opening is used for discharging. The feeding hopper assembly includes a feeding hopper 2, a rotating shaft 5 and a feeding pipe 3, and the feeding hopper 2 passes through the rotating shaft. 5 The rotation is arranged inside the casing 1, the feed pipe 3 is arranged at the center of the casing 1, one end of which is sleeved inside the rotating shaft 5, and the other end is arranged outside the casing 1, and the feed pipe 3 is used for In bringing the raw materials in the feed hopper 2 into the device, the feed hopper 2 has four, which are evenly arranged on the rotating shaft 5, and the feed hopper 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com