Continuous building jacking system and jacking method thereof

A building and jacking technology, which is applied in the direction of lifting devices, can solve the problems of inability to carry out jacking construction, long construction period, and small pre-jacking force, and achieve low construction difficulty, low construction cost, and high jacking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

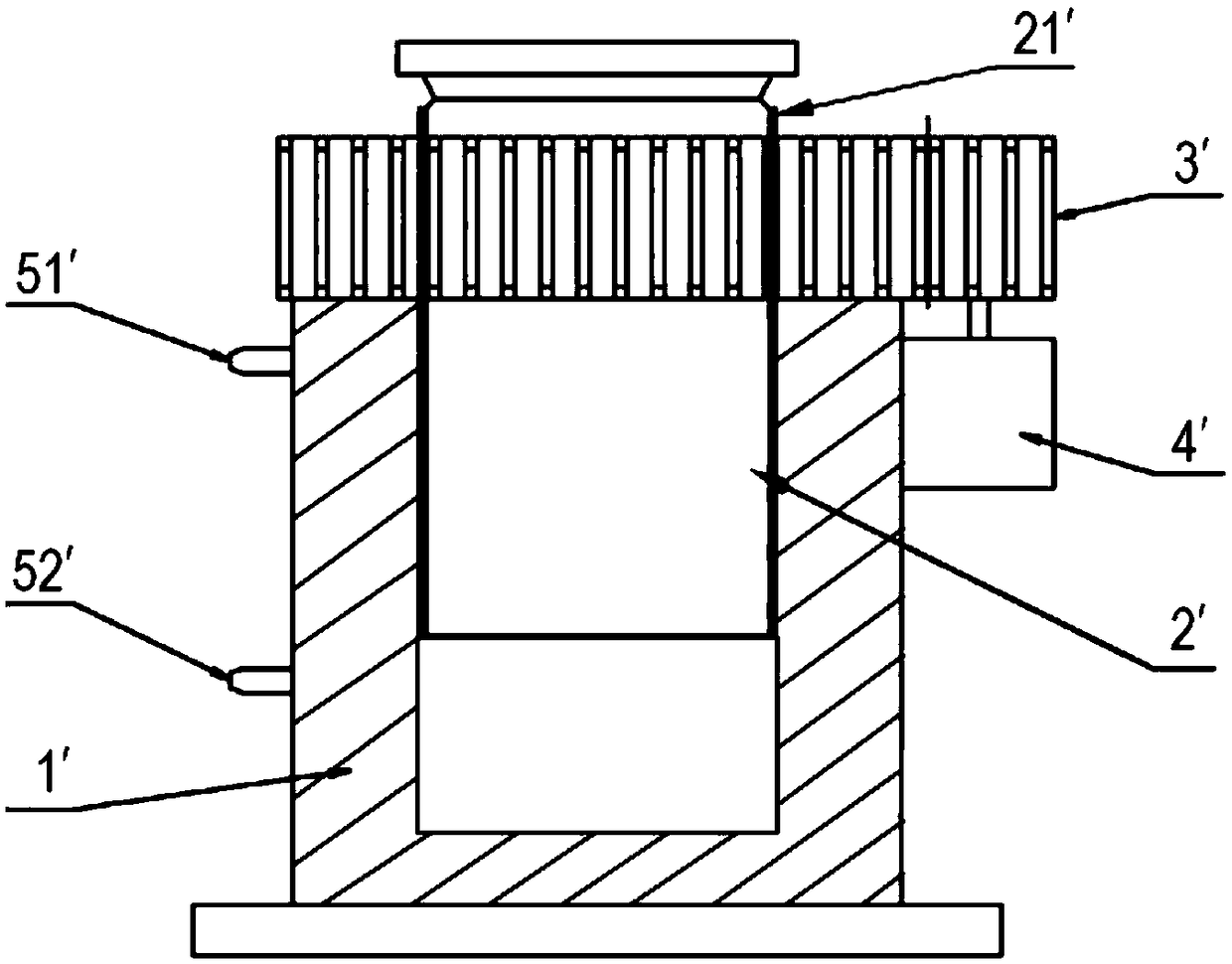

[0051] like figure 1 In the building continuous jacking system provided by the present invention, a kind of mechanical self-protection jack is shown in the cross-sectional structure schematic diagram:

[0052] A mechanical self-protection jack, including: a hydraulic jack composed of an oil cylinder 1' and a piston rod 2' that can be lifted or retracted on the oil cylinder 1', and an internal thread provided on the lifting ring 3' and the lifting ring 3' (Not shown in the figure) A mechanical self-protection assembly composed of the associated mechanism formed by the outer peripheral thread 21' provided on the piston rod 2', the oil motor 4' and the connecting pipeline.

[0053] from figure 1 can be seen in:

[0054] Lifting ring 3' is sleeved on the outside of piston rod 2' and through the engagement of its internal thread (not shown in the figure) with the outer peripheral thread 21' of piston rod 2' to form an associated mechanism, so that the relationship between lifting...

Embodiment 2

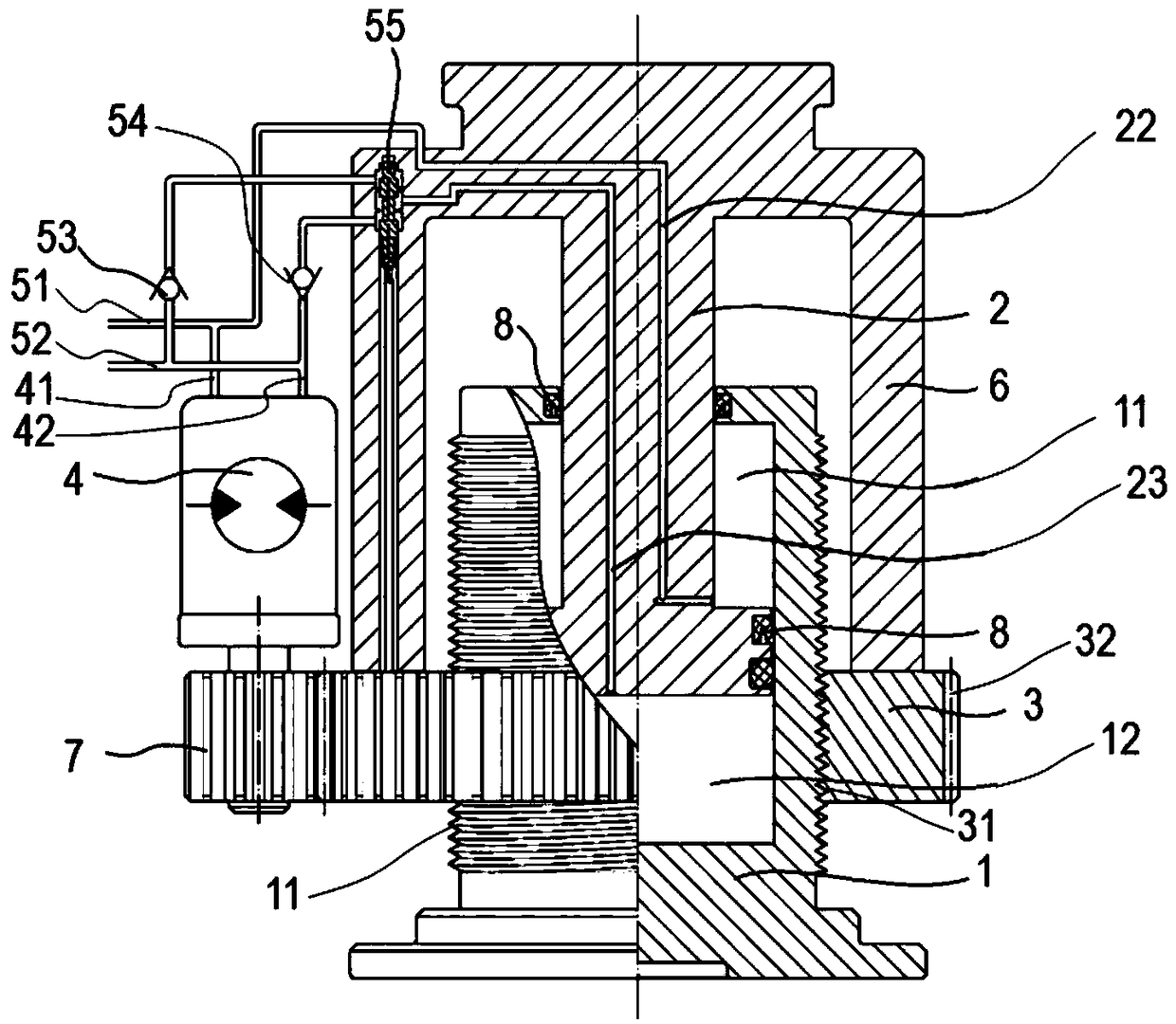

[0059] like figure 2 , in the building continuous jacking system provided by the present invention, a kind of sectional structural schematic diagram of the mechanical self-protection jack with driving gear is as shown:

[0060] A mechanical self-holding jack with a driving gear, comprising:

[0061] The oil cylinder 1 and the piston rod 2 that can be lifted or retracted on the oil cylinder 1, the mechanical self-protection components include the lifting ring 3, the associated mechanism, the oil motor 4, and the connecting pipeline;

[0062] The associated mechanism includes a driving gear 7 with internal teeth (not shown in the figure), an inverted U-shaped piston cover 6 fixed on the top of the piston rod 2, and an external tooth 32 provided on the outer periphery of the lift ring 3 and an inner ring provided on the inner ring. The thread 31 and the external thread 11 arranged on the outer periphery of the oil cylinder 1 make the lifting ring 3 connect with the oil cylinder...

Embodiment 3

[0076] Use the building continuous jacking system provided by the present invention to carry out the method for building jacking, comprising the following steps:

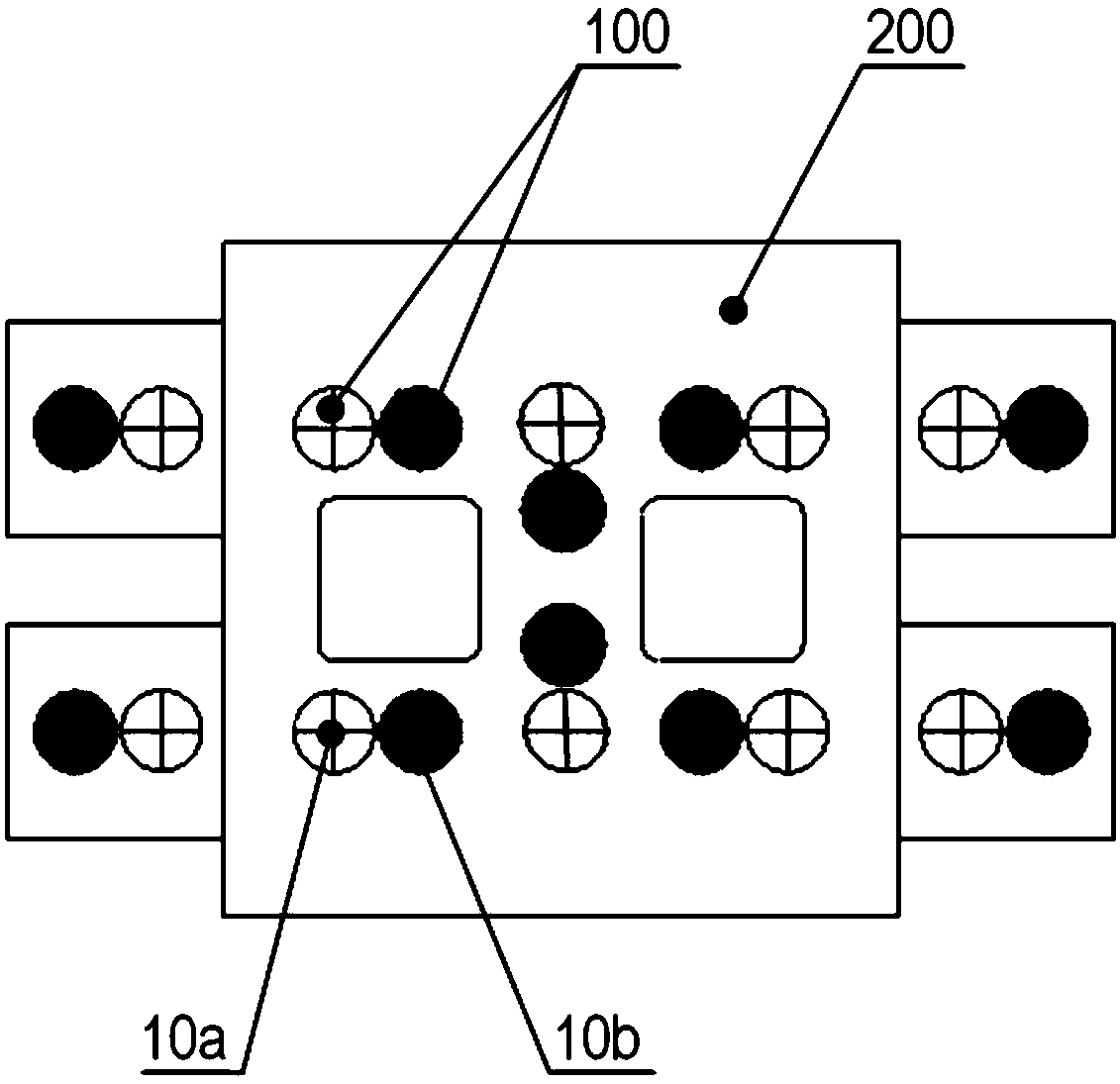

[0077] First, after adding the safety factor to the weight of the building 200, divide it by the jacking force of each mechanical self-protection jack, and calculate the required jacking capacity in the building continuous jacking system of the present invention when the building 200 is continuously jacked up. After obtaining the required quantity, according to the structural characteristics of the building 200, the jacking device 100 is arranged under the building; as image 3 When using a building continuous jacking system provided by the present invention to lift a building, the schematic diagram of the cross-sectional layout of the jacking device is shown.

[0078] Then, a mechanical self-protection jack 10a arranged in each jacking device 100 below the building 200 is started to lift through the console and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com