Control system and method of power-operated tailgate based on millimeter wave

A control system and millimeter wave technology, applied in specific array feeding systems, circuits, electrical components, etc., can solve the problems of easy failure, large interaction of capacitance, etc., and achieve high space utilization, low feed loss, Feed network simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

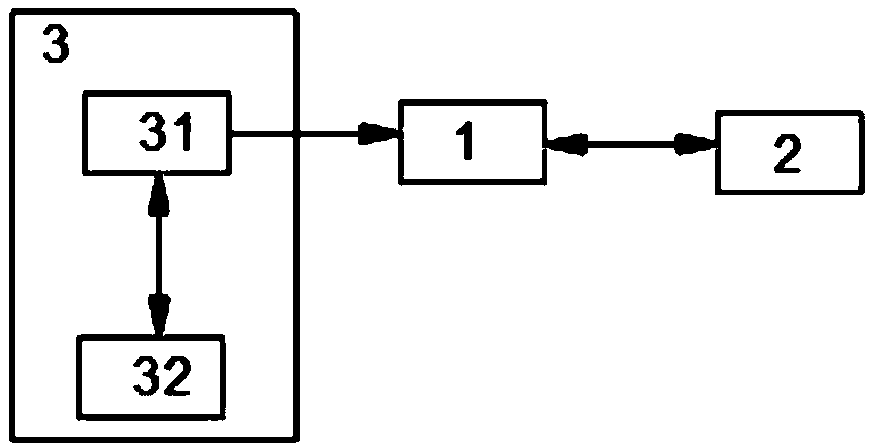

[0035] Embodiment: a kind of electric tailgate control system based on millimeter wave, such as Figure 1 to Figure 4 As shown, it includes an electric tailgate control unit 1, an electric tailgate execution unit 2, and a millimeter-wave detection unit 3 for collecting kick signals, and the millimeter-wave detection unit is connected to the electric tailgate control unit for signals. The electric tailgate control unit is electrically connected to the electric tailgate execution unit;

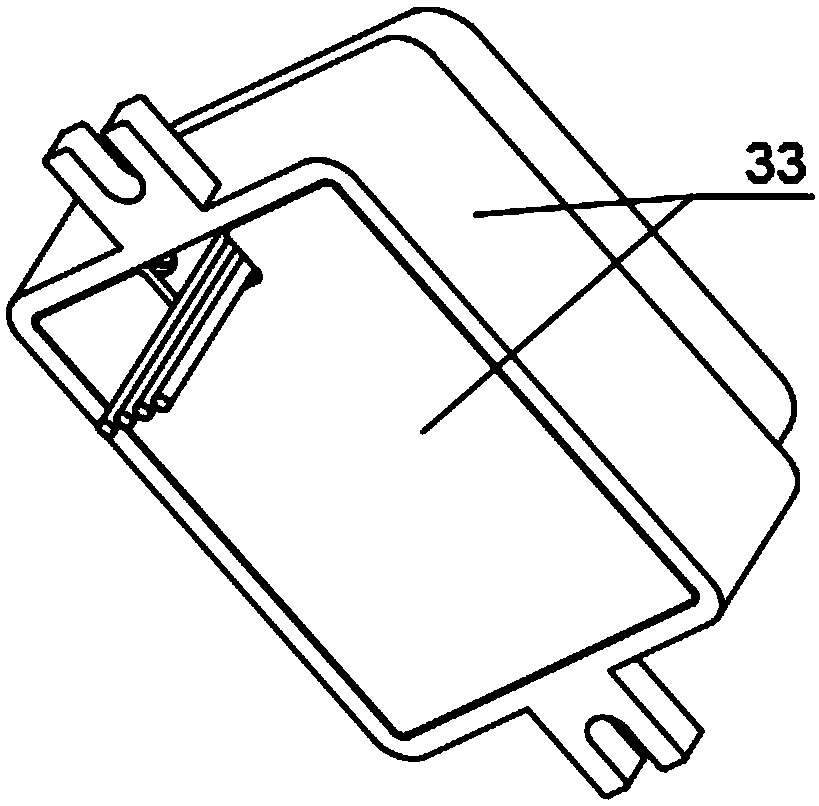

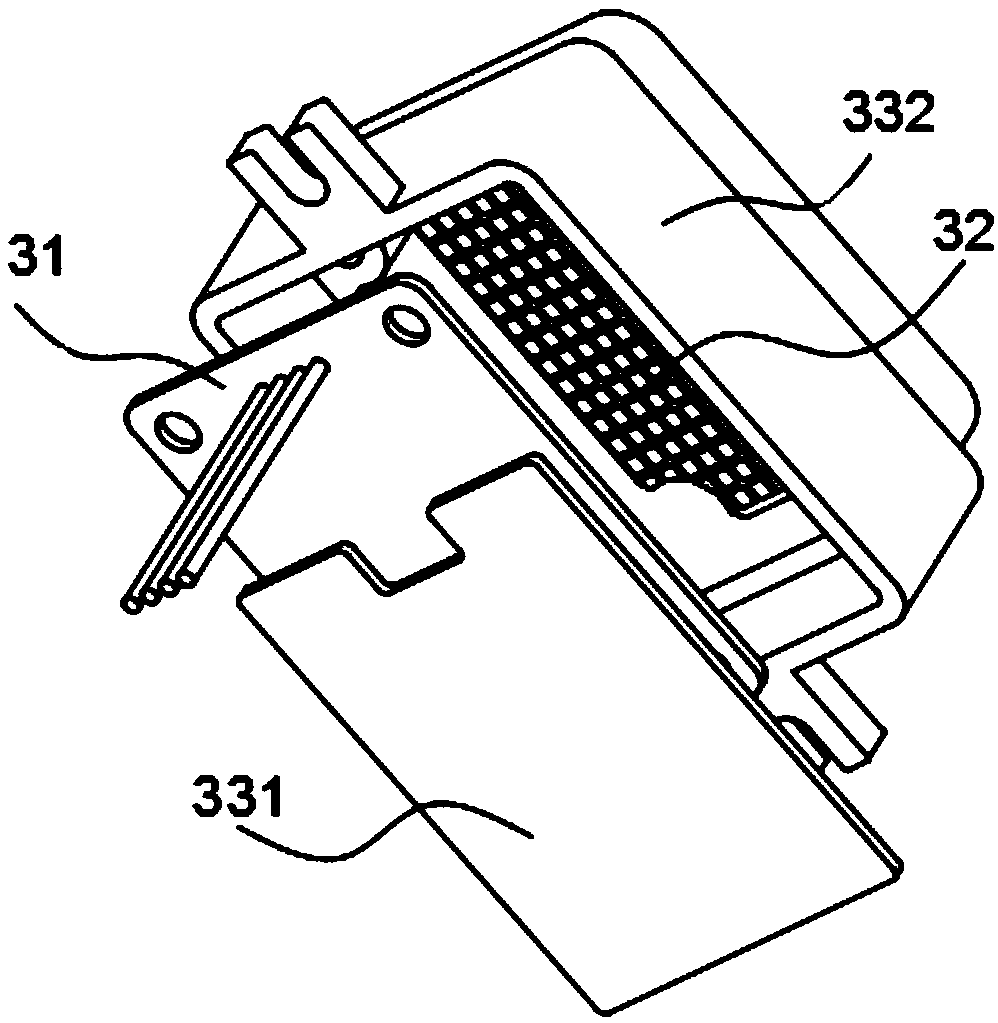

[0036] The millimeter-wave detection unit includes a millimeter-wave sensor, the millimeter-wave sensor includes a millimeter-wave control component 31 and a microstrip array antenna 32 for detecting kick signals, and the microstrip array antenna is mounted on the millimeter wave For a wave sensor, the millimeter wave control component is connected to the microstrip array antenna for signals, and the millimeter wave control component is connected to the electric tailgate control unit for signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com