Device and method for heating butterfly valve

A technology of heating device and butterfly valve, which is applied in the direction of valve heating/cooling device, valve device, lifting valve, etc., which can solve the problems such as inability to open, achieve the effect of compact structure, easy operation, improved work efficiency and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

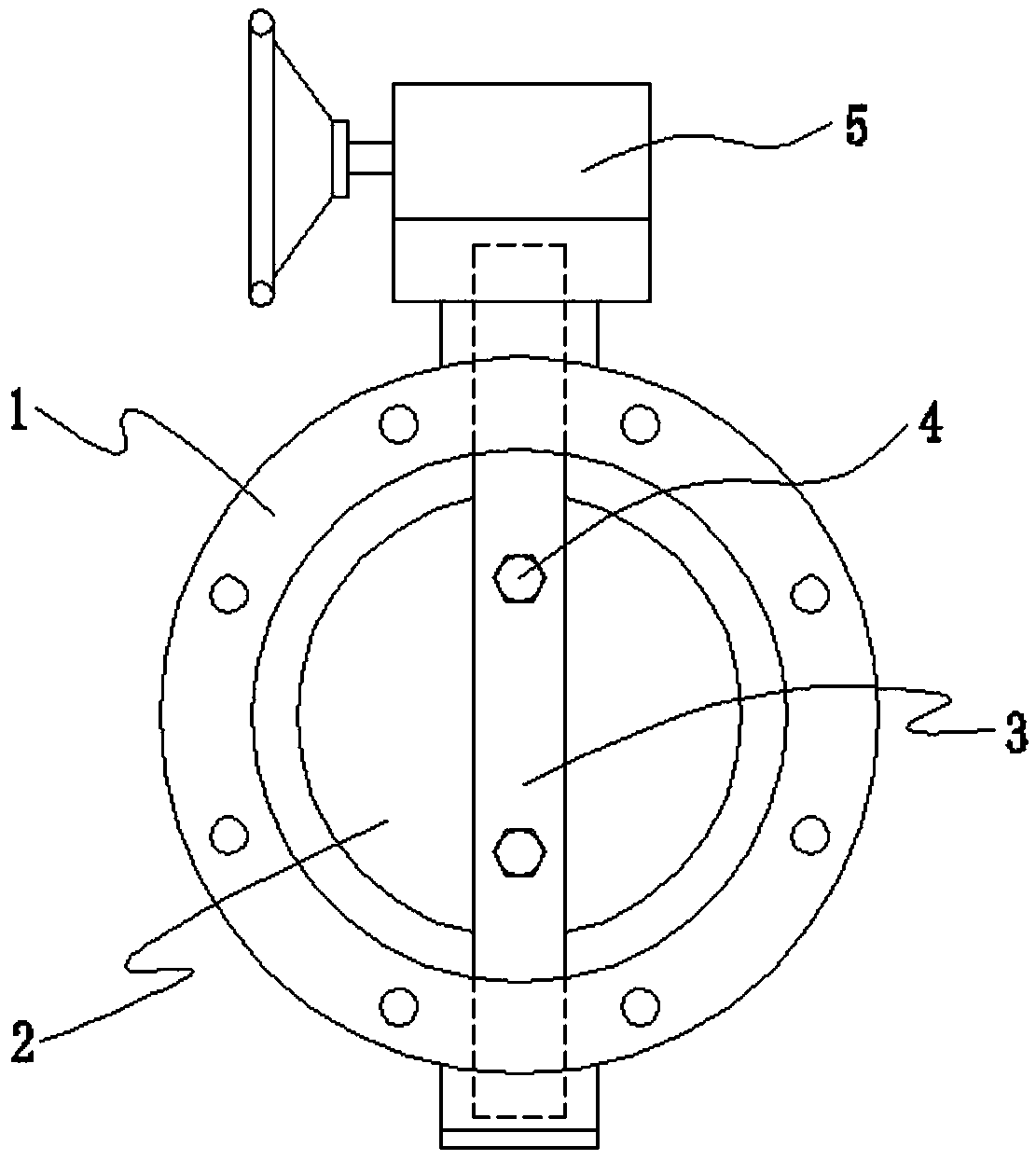

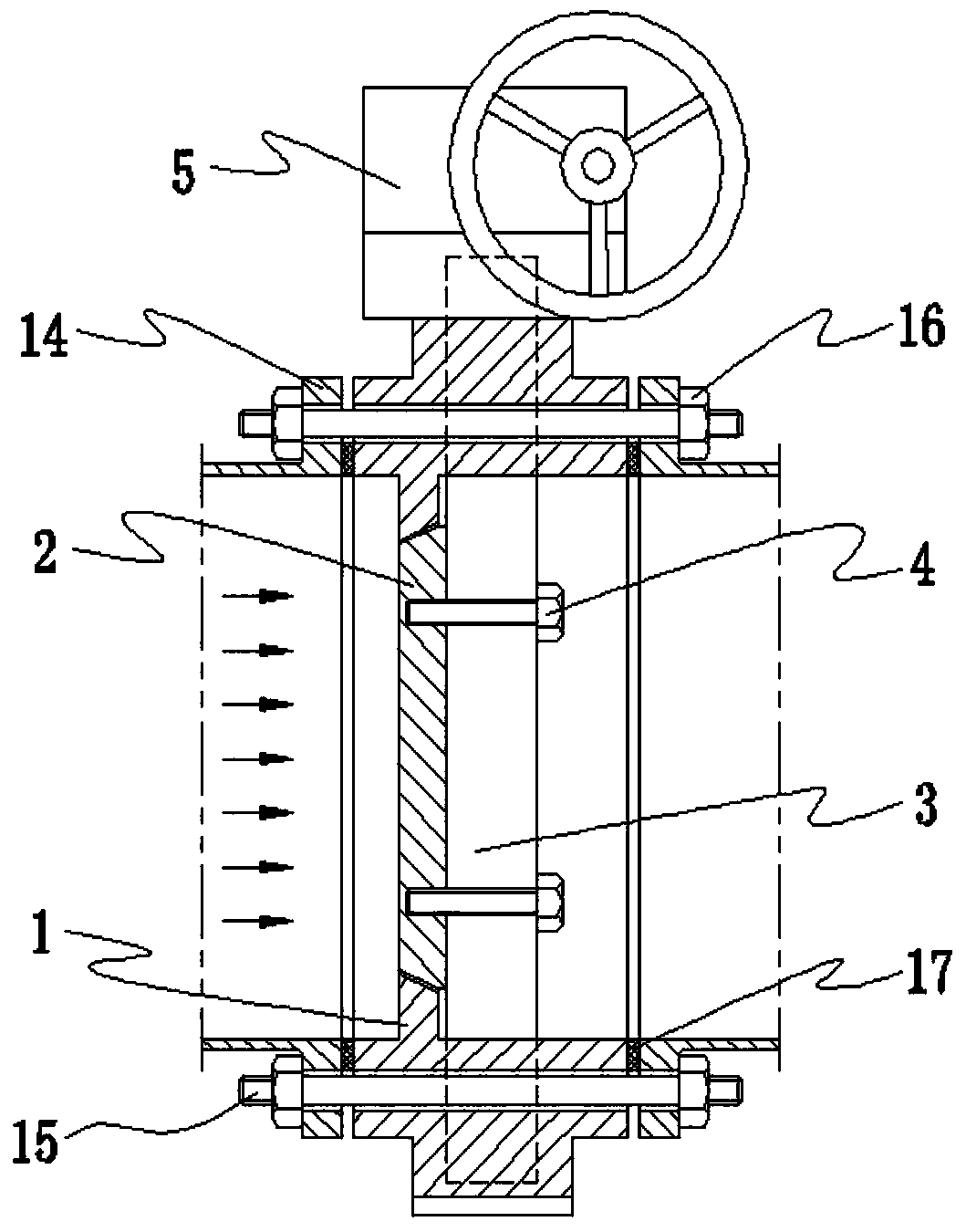

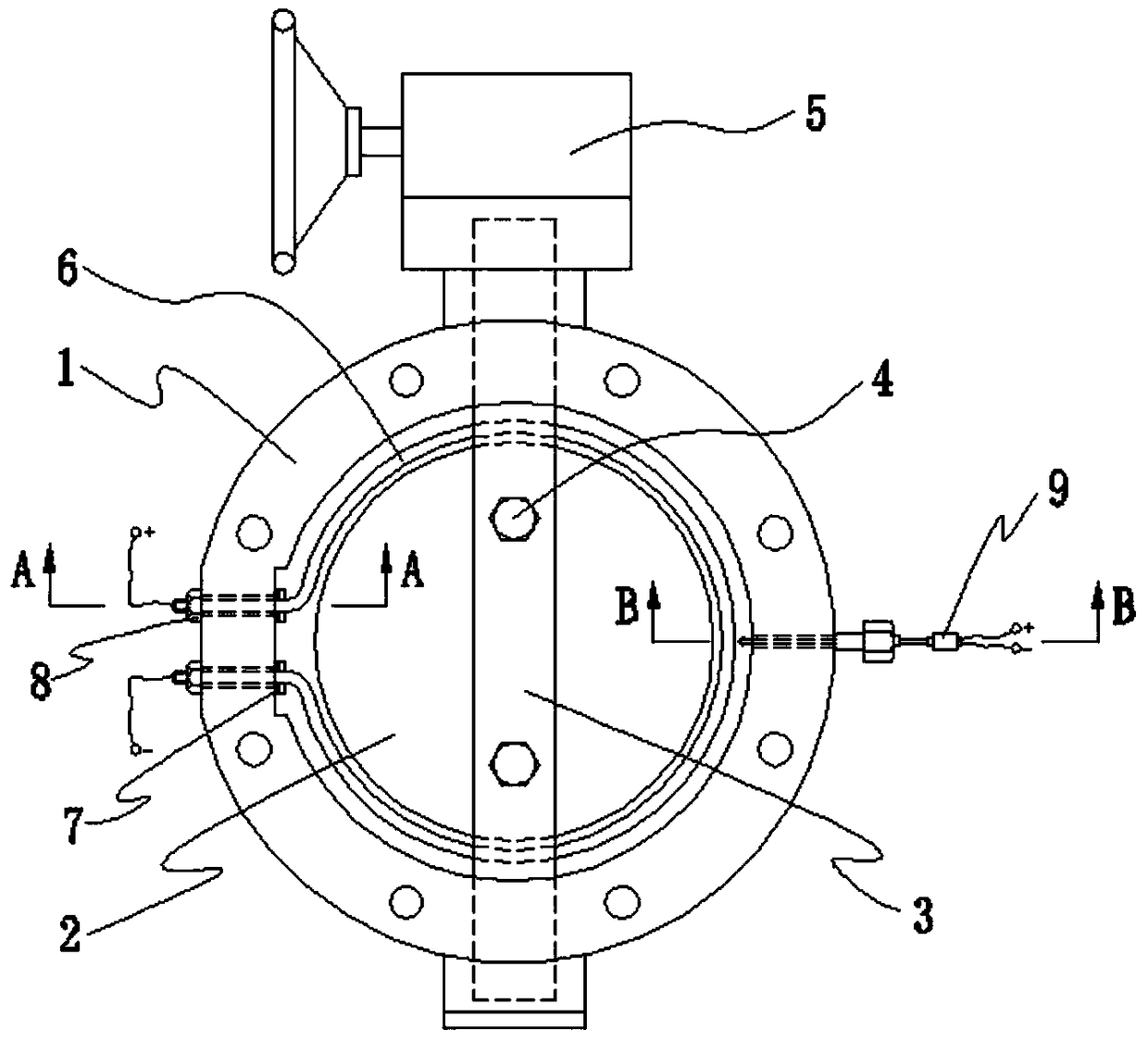

[0026] Such as figure 1 with figure 2 As shown, the general-purpose butterfly valve used in the gas pipeline is mainly composed of a valve body 1, a butterfly plate 2, a main shaft 3, a main shaft connecting bolt 4 and an actuator 5. The actuator 5 can be manual, electric or pneumatic, and the butterfly valve body 1 is placed Place the pipeline gasket 17 between the two pipeline flanges 14 and between the pipeline flange 14 and the valve body 1, the pipeline connecting bolts 15 pass through the bolt holes of the pipeline flange 14 and the valve body 1, and both ends are inserted into the pipeline Attach the nut 16 and tighten so that the fluid in the pipe will not flow out. In order to meet the requirements of processing the sealing surface, the valve body 1 is designed as a structure that partially shrinks inward, forming an inward boss, and the annular inner surface of the boss is processed as the sealing surface corresponding to the butterfly plate 2. The flow direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com