Wireless temperature-measurement monitoring device and method of high-voltage cable connector

A high-voltage cable, wireless temperature measurement technology, used in measurement devices, thermometers using electrical devices, and thermometers that are directly sensitive to heat and other problems to achieve the effect of solving energy consumption problems, reducing engineering workload and reliable communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

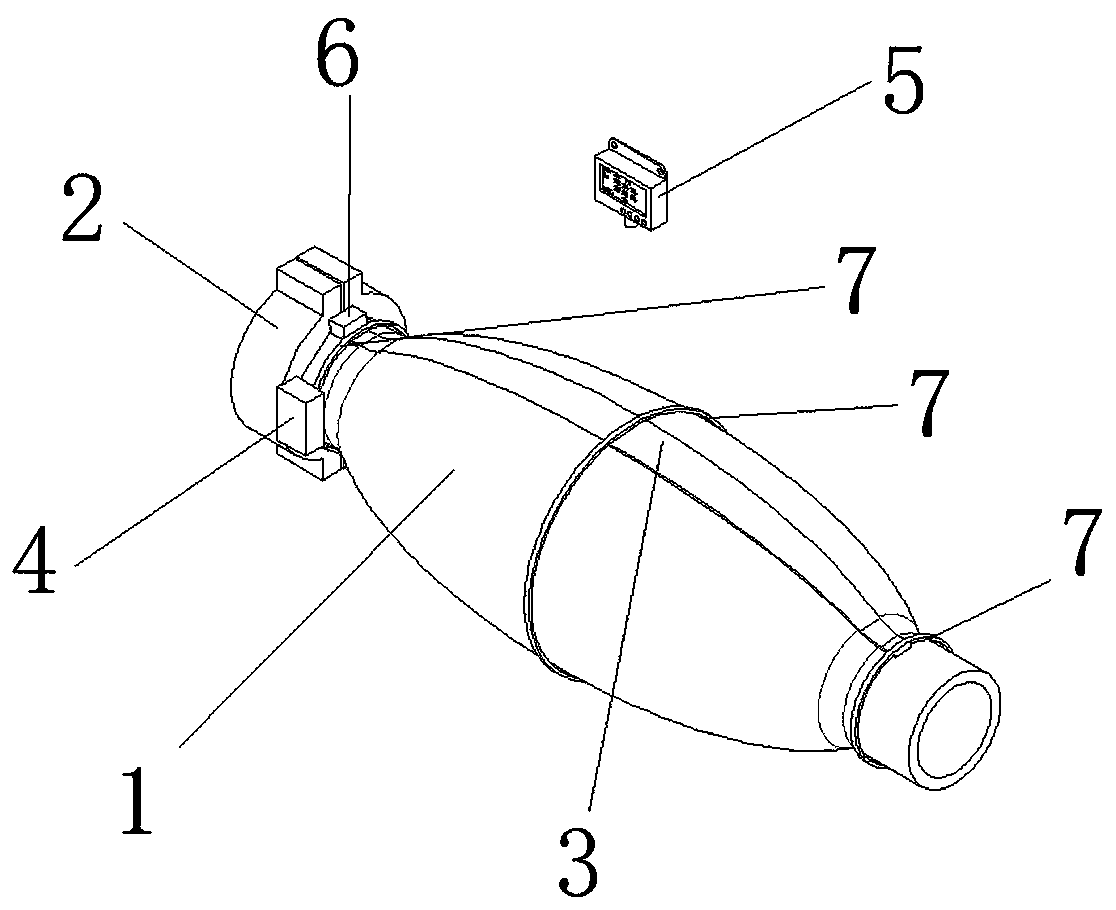

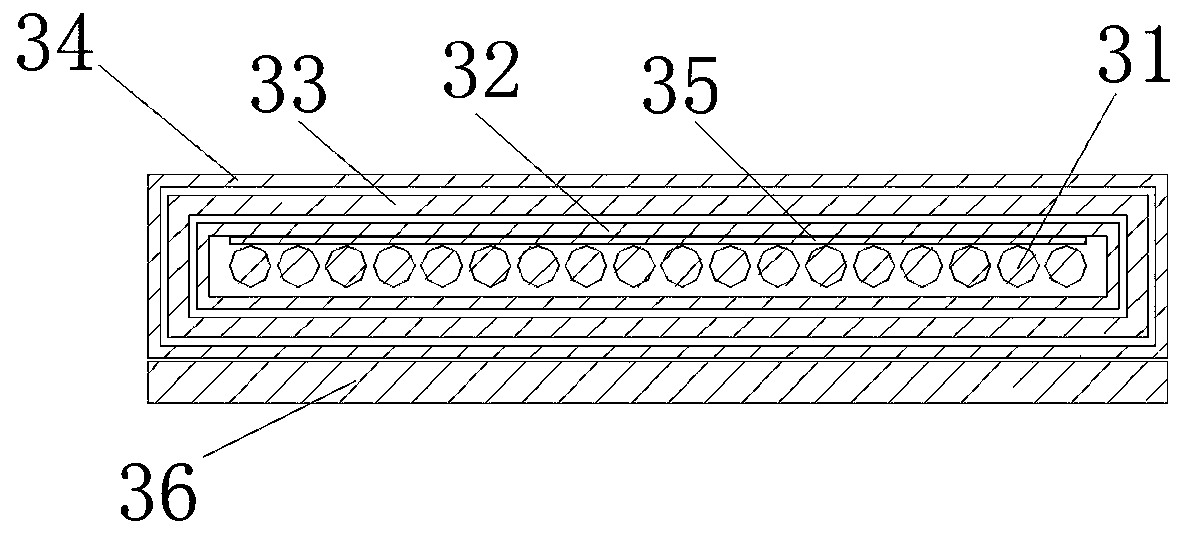

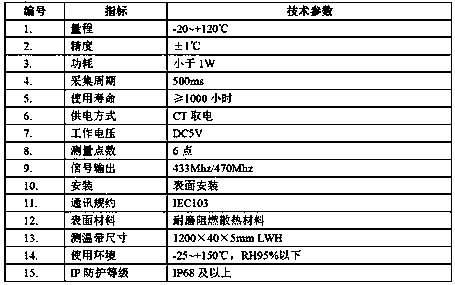

[0041] The invention provides a wireless temperature measurement and monitoring device for high-voltage cable joints, such as figure 1 As shown, it includes: an induction power-taking unit 2 arranged at one end of the high-voltage cable joint body 1, a strip-shaped temperature measurement unit 3 attached to the outer circumference of the high-voltage cable joint body and connected to the induction power-taking unit, and a high-voltage cable joint The acquisition and wireless communication unit 4 connected to the reaction power-taking unit and the strip temperature measurement unit at one end of the body, and the on-site centralized display unit 5 set at the high-voltage cable joint site and wirelessly matched with the acquisition and wireless communication unit. The strip temperature measurement unit includes a strip sensor and a waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com