Melt containment retention system

A molten material and containment technology, applied in the field of molten material containment retention system, can solve the problems of being unable to effectively deal with the overall drop of the lower head and effectively resisting the impact of the molten material, so as to reduce the risk of radioactive leakage and high latent heat absorption Ability, the effect of increasing the collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

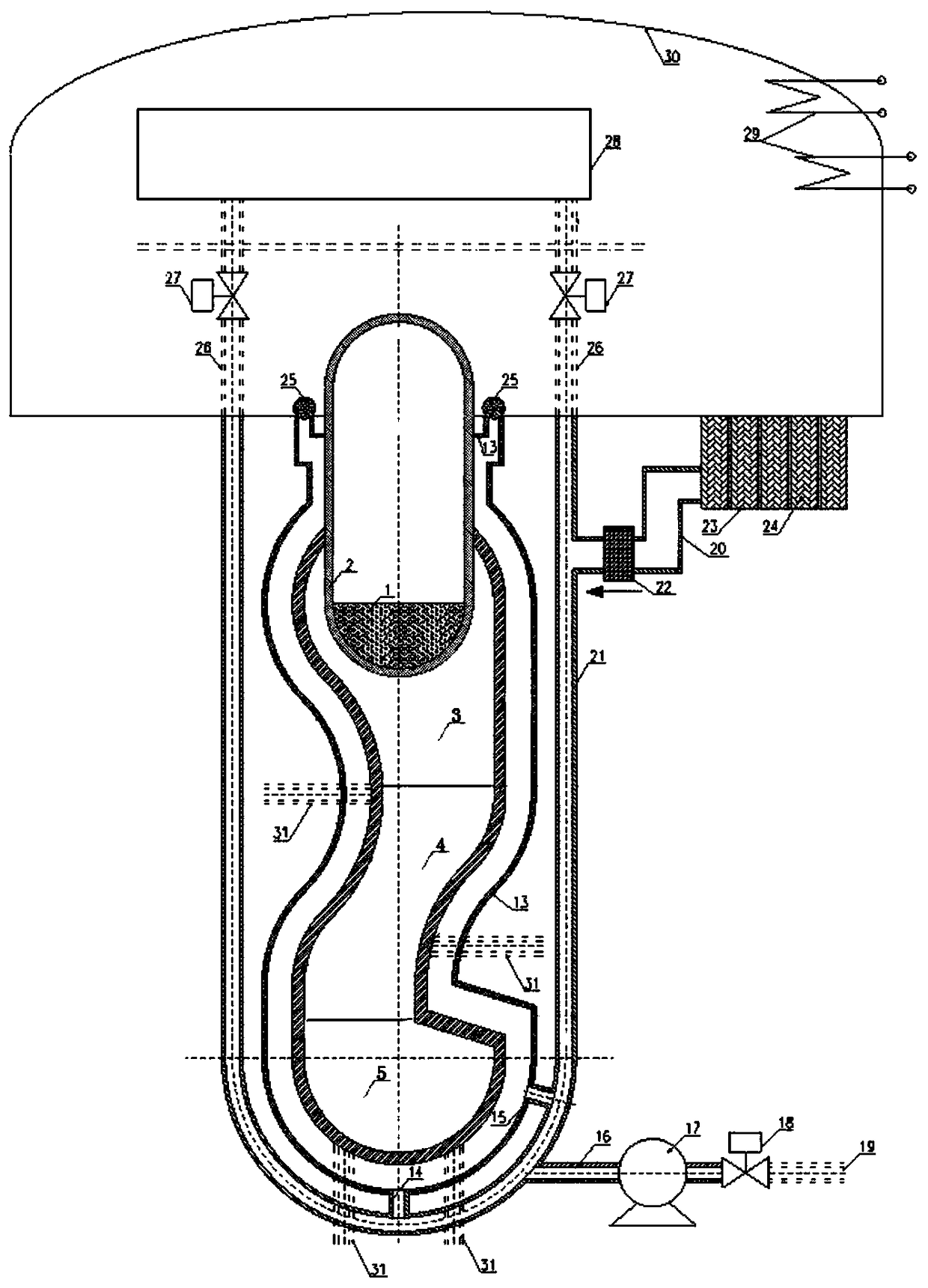

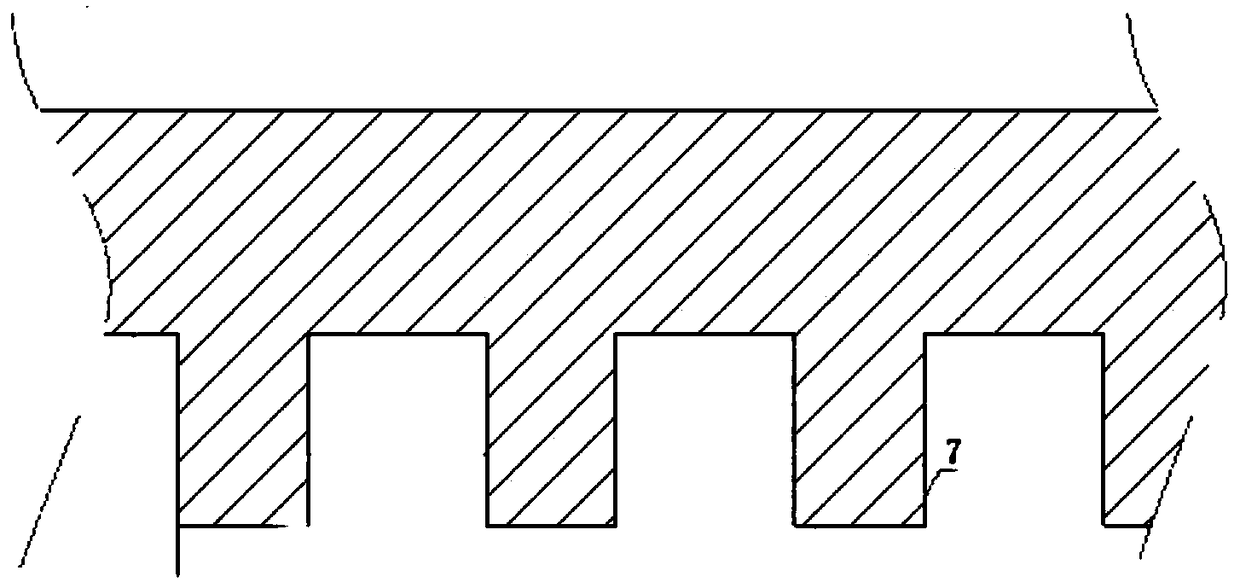

[0039] Such as figure 1 , 2 As shown, a melt containment retention system includes a retention part and a cooling system for cooling the retention part. The cooling system includes a connected cooling source device and a cooling water circuit. The cooling water circuit is connected to the retention part. The retention part includes a jacket The melt extension cavity is located outside the pressure vessel 2 and extends downward. The melt extension cavity is formed by surrounding the pressure vessel 2 with the first container 6 prepared by the cooling plate. The melt extension cavity flows along the flow direction of the melt 1 It has at least one first curved section buffer zone 3 for buffering the flow velocity of the molten material 1, at least one second curved section slow zone 4 for extending the flow channel and narrowing the flow channel, and a loading area at the bottom of the molten material extension chamber 5. The direction of curvature of both the buffer zone 3 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com