A support mechanism of a pressure transformer

A technology of transformer and support mechanism, which is applied in the direction of transformer/reactor installation/support/suspension, transformer/inductor cooling, etc. It can solve problems such as inconvenient installation, low work efficiency, and inconvenient adjustment of support height, etc., to achieve Easy to install, improve the anti-skid effect, and improve the effect of cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

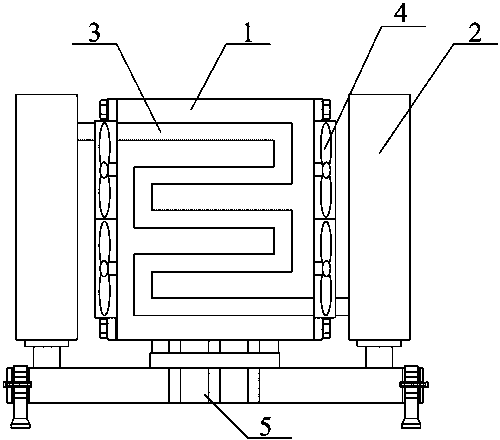

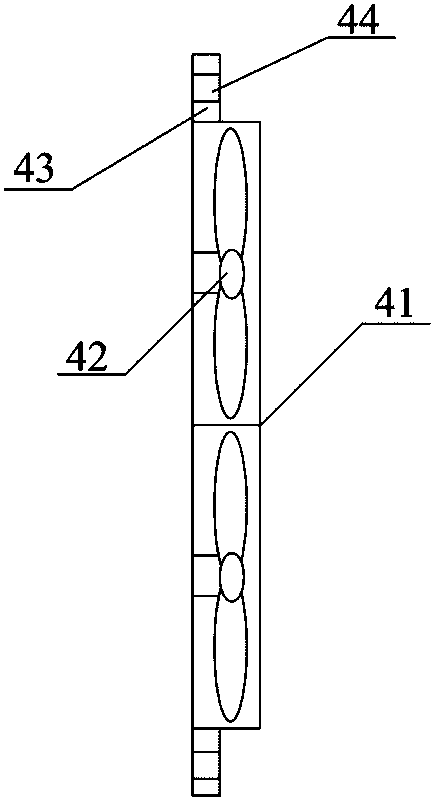

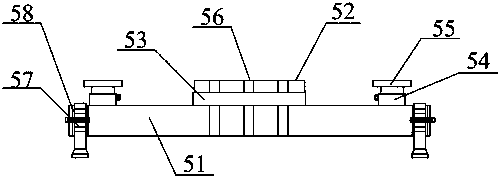

[0026] as attached figure 1 to attach Figure 4 shown

[0027] The present invention provides a support mechanism for a transformer, which includes a transformer 1, a water storage tank 2, a water pipe 3, an air blast cooling device 4 and a fixed base 5, and the transformer 1 is installed on the middle and upper part of the fixed base 5 The 4 bolts of the blast cooling device are installed on the left and right sides of the transformer device 1; the water pipes 3 are fixed on the front and rear sides of the transformer device 1; Both sides are installed on the top of the fixed base 5; the water pipe 3 is connected to the water storage tank 2; the fixed base 5 includes a base 51, a transformer bracket 52, a shock absorber 53, and a water storage tank bracket 54, Fixed plate 55, heat dissipation holes 56, supporting legs 57 and adjustment channels 58, the transformer brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com