Constant power LED driver

A technology of LED driver and constant power, applied in the field of LED linear constant current driver, can solve the problems of LED efficiency decrease, input power increase, driver efficiency decrease, etc., and achieve the effect of good LED drive efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

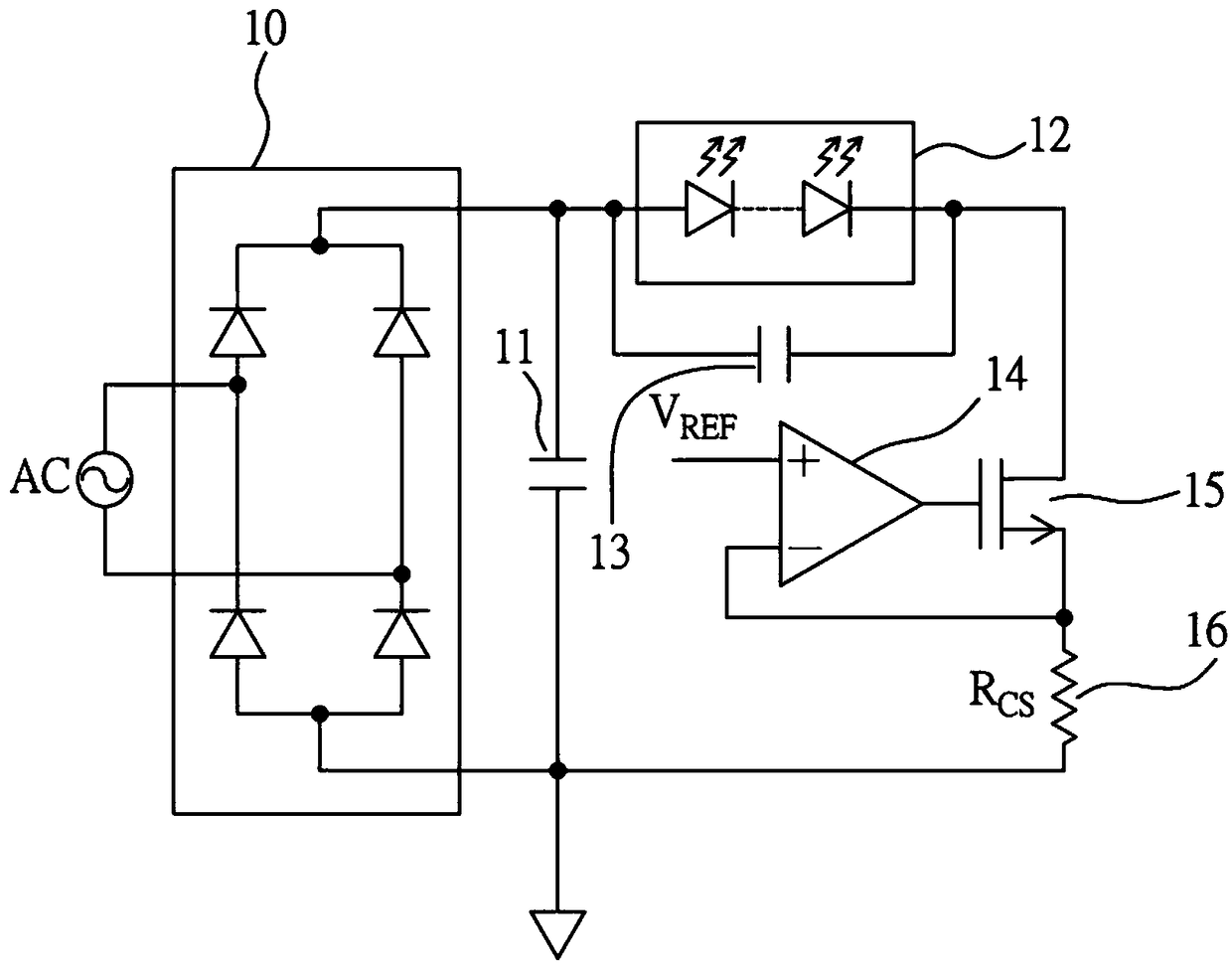

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the structure, features and purpose of the present invention, it will be described in detail in conjunction with the accompanying drawings and preferred specific embodiments.

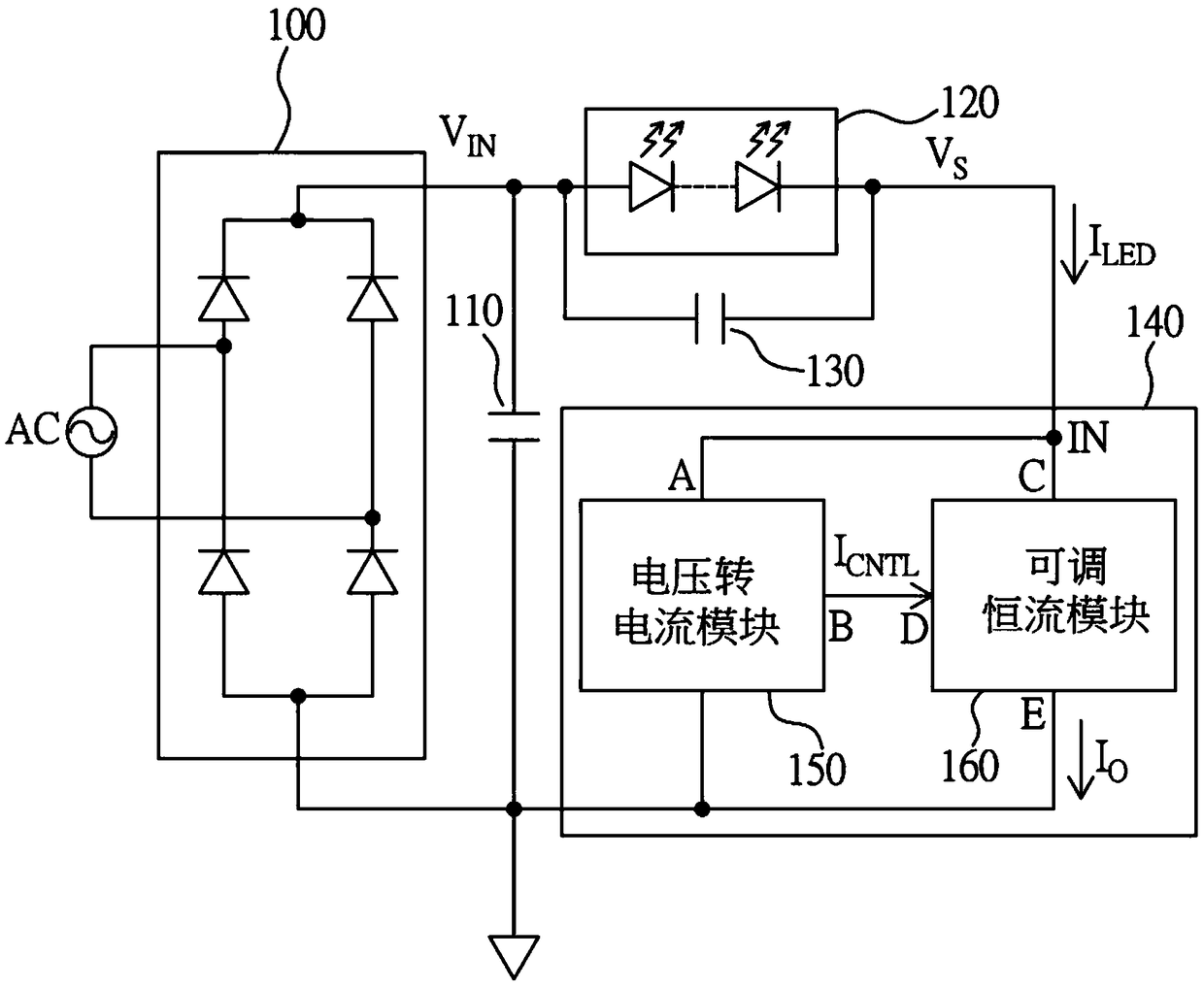

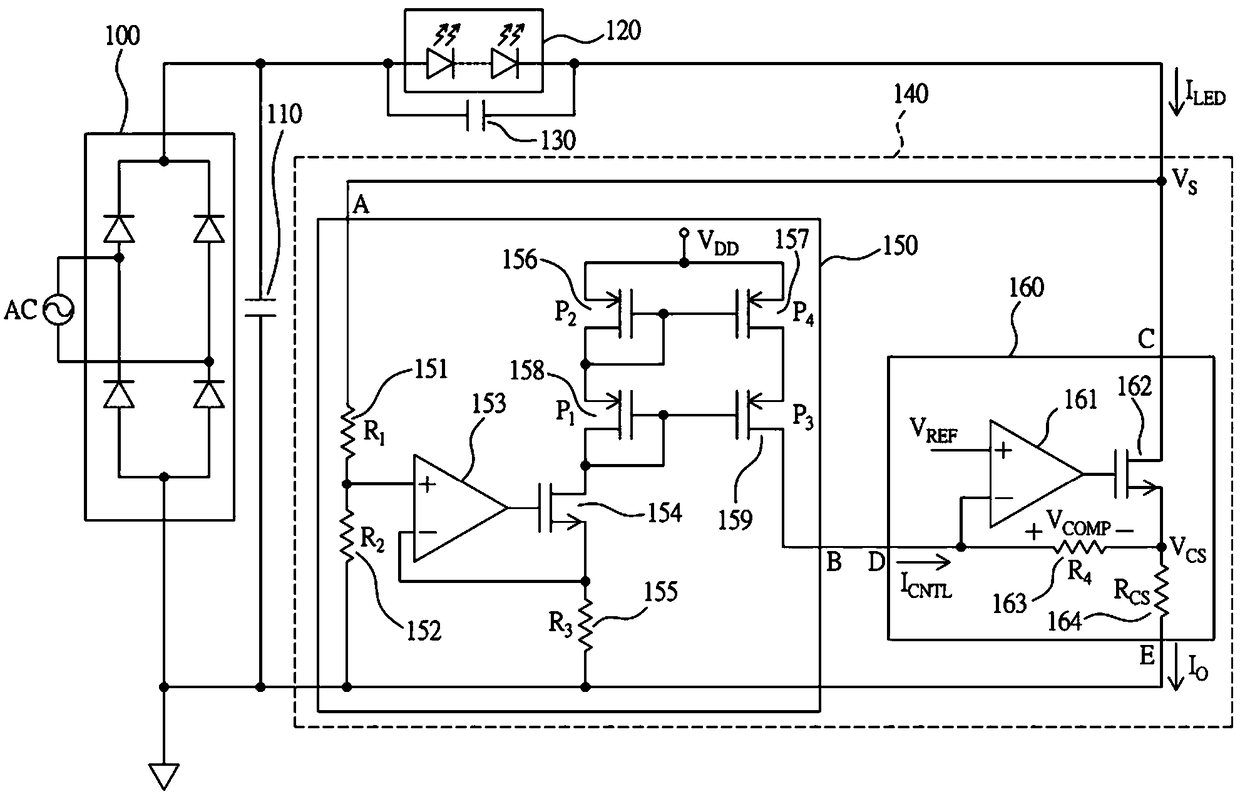

[0035] Please refer to figure 2 , which shows a circuit diagram of an embodiment of the constant power LED driver of the present invention. As shown in Figure 2, an LED lighting device includes a rectifier module 100, a filter capacitor 110, an LED string 120, a filter capacitor 130 and a constant power LED driver 140, and the constant power LED driver 140 includes a voltage-to-current module 150 And an adjustable constant current module 160 .

[0036] exist figure 2 In the circuit, the constant power LED driver 140 has a voltage input terminal IN to couple with the cathode of the LED string 120, the anode of the LED string 120 is used to couple with a DC voltage VIN, the rectifier module 100 and the filter capacitor 110 In parallel, the LED string 120 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com