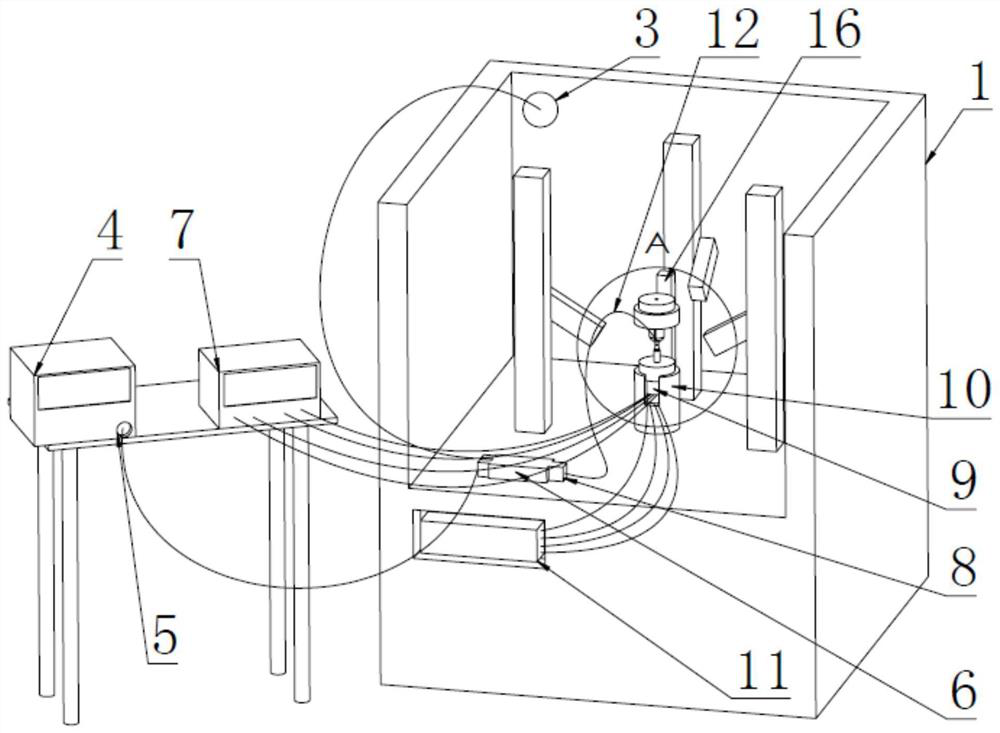

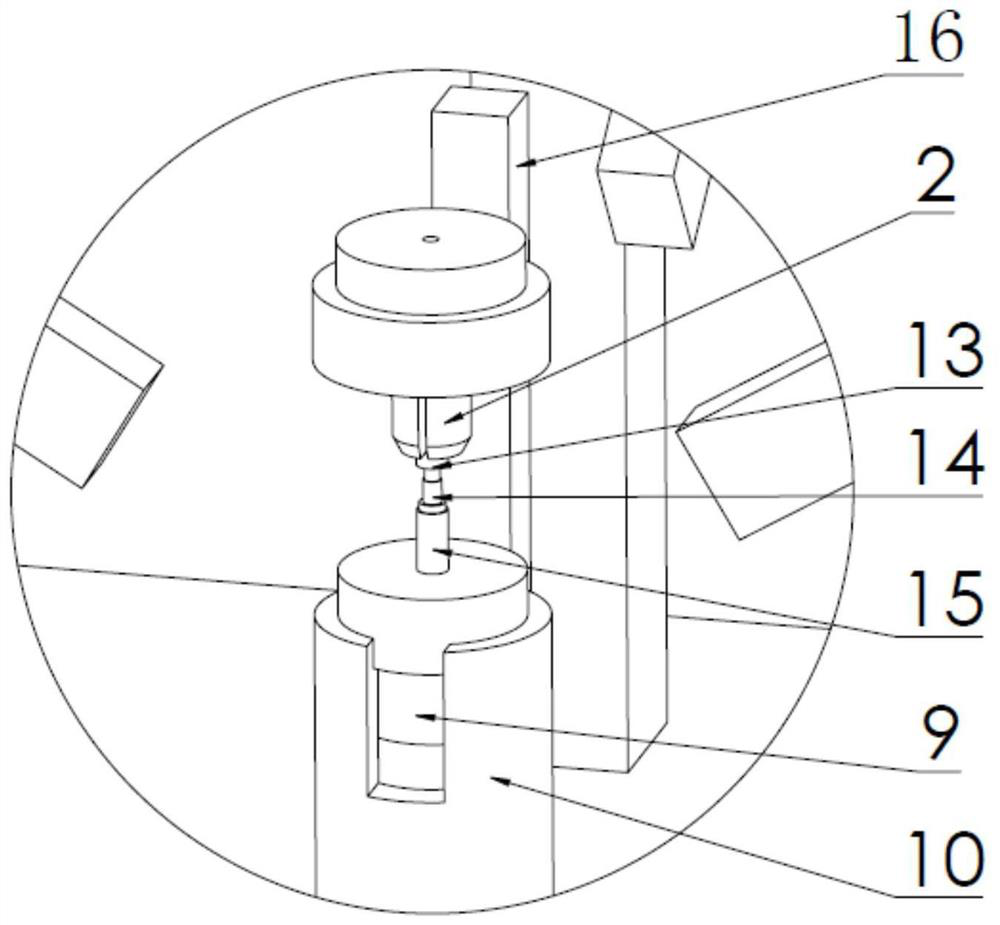

Communication laser temperature control coupling welding device

A welding device and laser technology are applied in the field of optical communication to achieve the effects of reducing repair costs, avoiding material loss and labor loss, and stabilizing fiber input power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

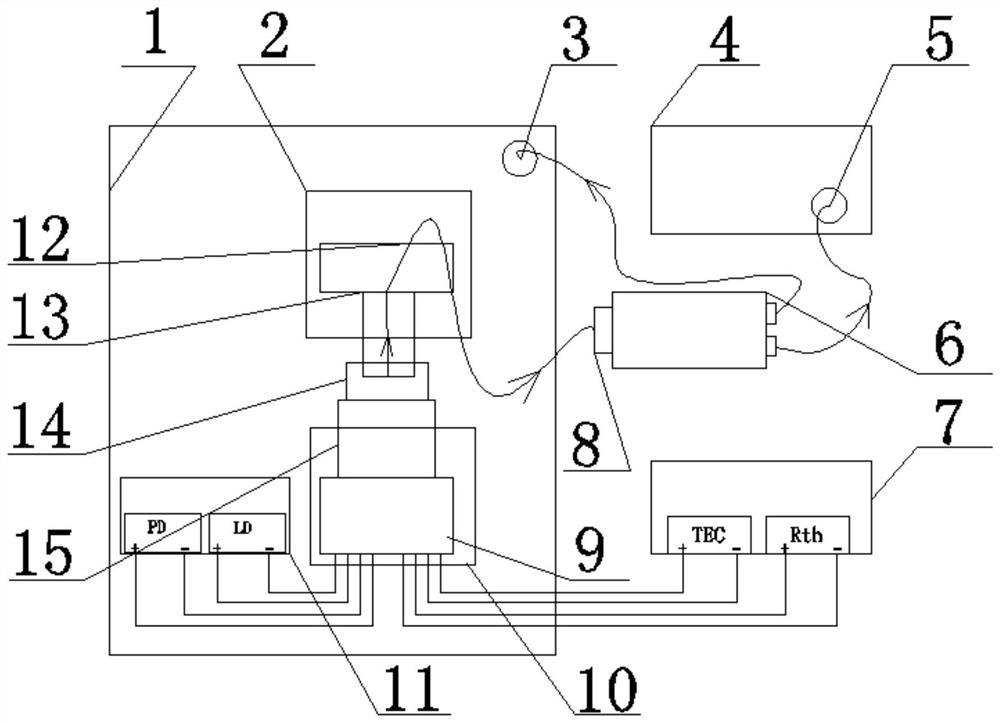

Method used

Image

Examples

Embodiment

[0034] The device of the present invention is used for temperature-controlled coupling welding: through temperature adjustment, the wavelength is locked, and then the fiber input power is welded to 2.5dBm, and the final inspection test is adjusted to the center wavelength. At different temperatures, the fiber input power is 2.5dBm, which can still guarantee normal temperature The power into the fiber when coupled at 25°C is 2.5dBm.

[0035] Table 2 temperature control coupling welding data of the present invention

[0036] parameter 1 2 3 4 5 Coupling welding into fiber power 2.5dBm 2.5dBm 2.5dBm 2.5dBm 2.5dBm final test temperature 50.5℃ 48.5℃ 47.2℃ 49℃ 50℃ Final test fiber input power 2.5dBm 2.5dBm 2.5dBm 2.5dBm 2.5dBm

[0037] By comparing the data of the comparison example with the example, it can be seen that the center wavelength is locked by temperature control during the coupling welding process, and the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com