Energy-saving controllable low-temperature freezing point pulverizing device

A crushing device and energy-saving technology, which is applied in the field of energy-saving and controllable low-temperature freezing point crushing devices, can solve problems such as unreasonable arrangement of hammers and knives, volatilization and loss of effective components, and unsatisfactory classification effects, so as to avoid repeated crushing, dust and airflow Smooth flow and reduced loss of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

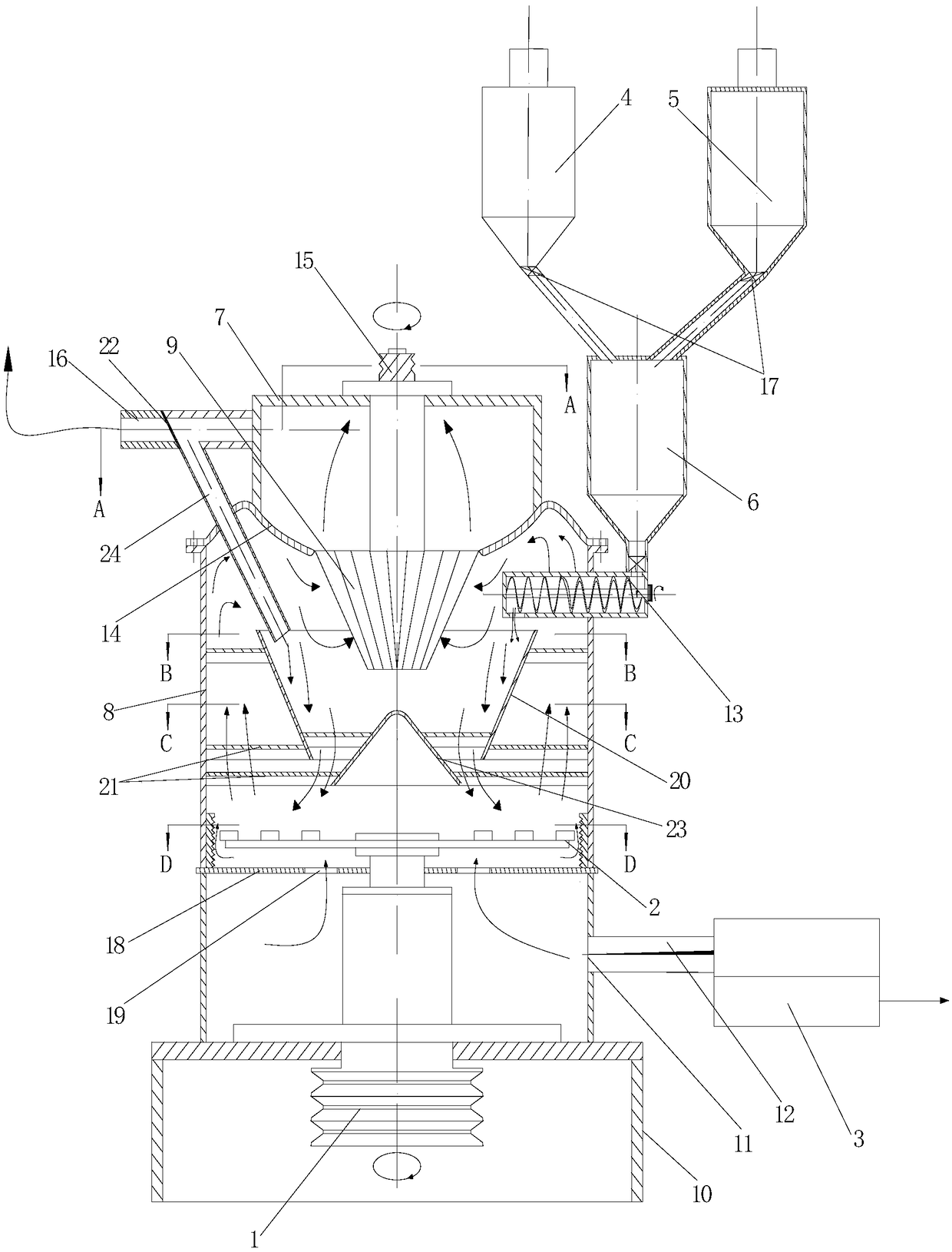

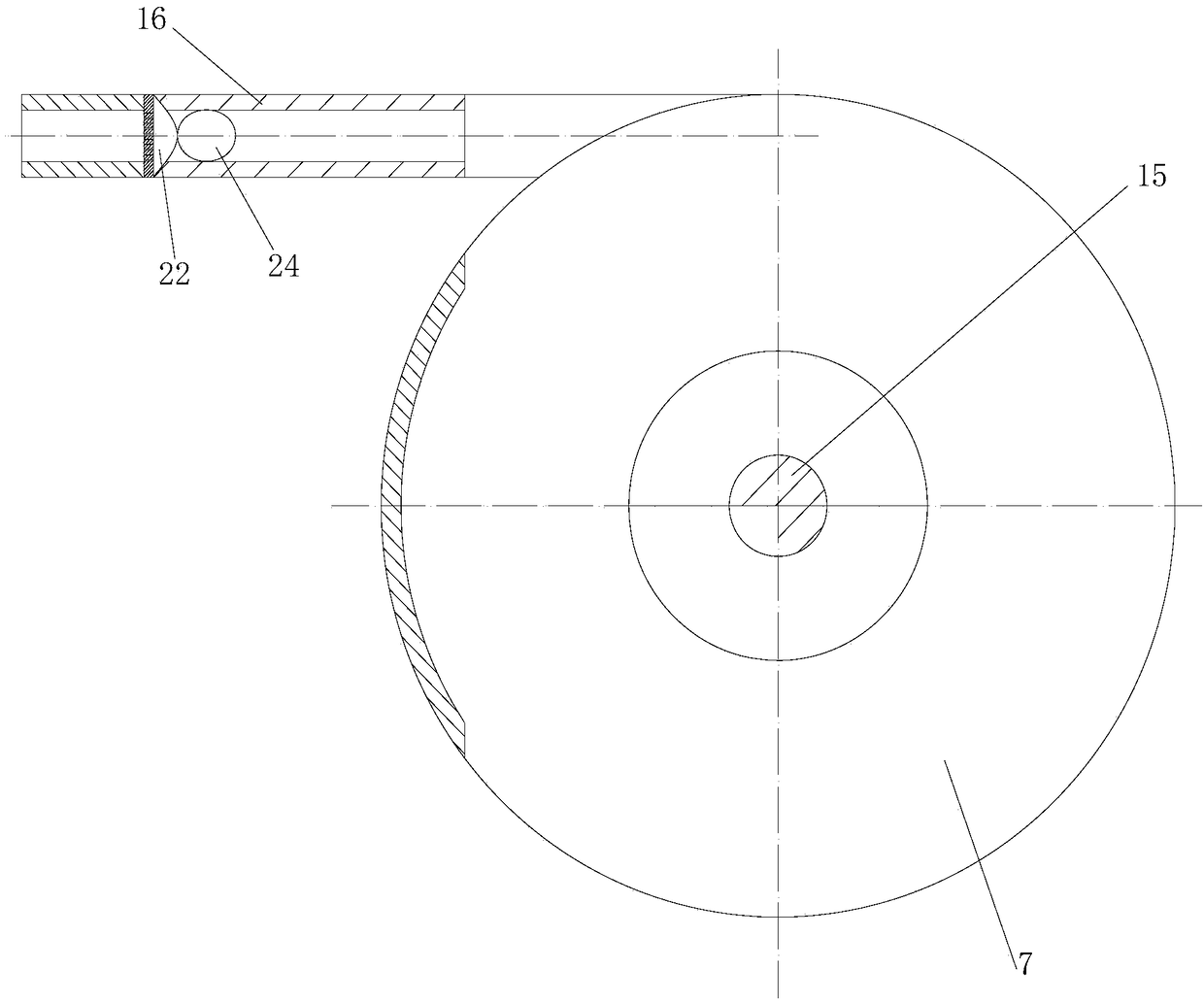

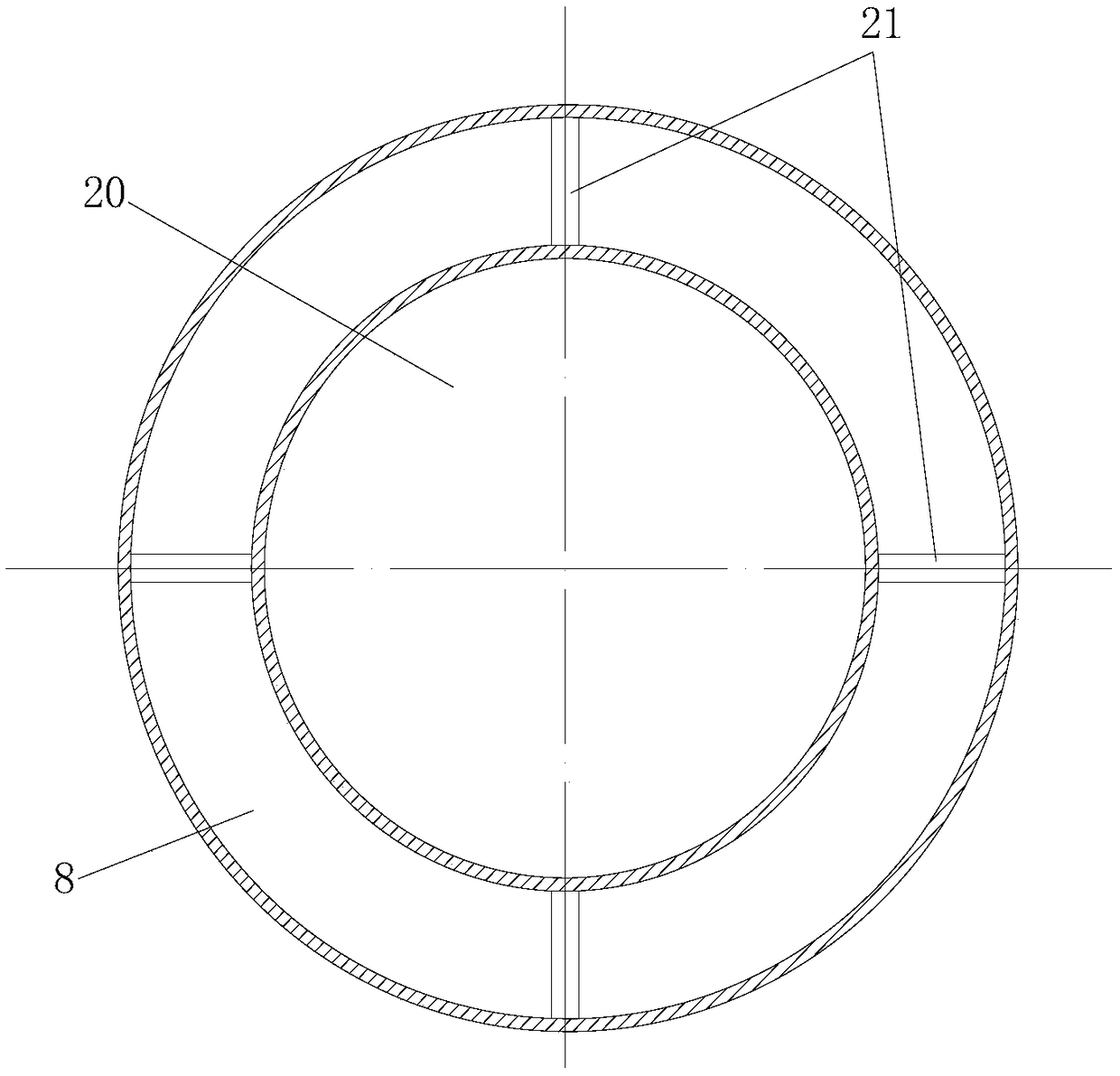

[0026] Such as figure 1 and figure 2 The shown energy-saving controllable low-temperature freezing point crushing device includes a crushing motor, a crushing mechanism, a heat pump, a material bin, a dry ice bin, a mixing bin, a classifying bin, a crushing bin and a classifying turbine. The crushing motor is installed on the side of the crushing bin through a base The lower end, the crushing mechanism is installed in the crushing bin, and the crushing mechanism is connected to the crushing motor; the lower end of the side wall of the crushing bin is provided with a cold air inlet communicating with the inner cavity of the crushing bin, and the cold air inlet is located at Below the crushing mechanism, the cold air inlet is connected to the cold air outlet of the heat pump through the cold air pipe; the material bin and the dry ice bin are both connected to the feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com