A glass bottle conveyor

A technology for glass bottles and jars and conveyors, applied in the directions of conveyors, transportation and packaging, can solve the problems of inconvenient operation, complexity and high manufacturing cost, and achieve the effects of simple structure, reasonable design and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

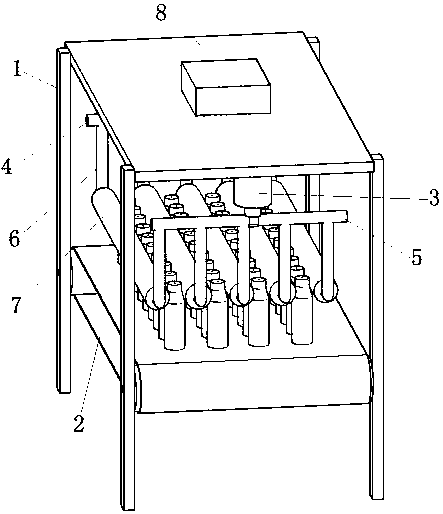

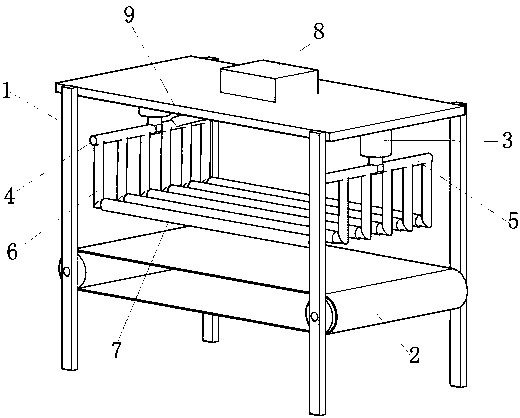

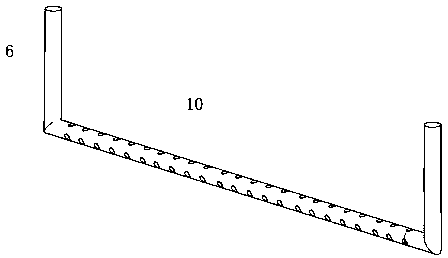

[0019] Such as Figure 1-3 In the shown embodiment, a conveyor for glass bottles and jars includes a frame body 1, a conveyor belt 2 arranged at the lower end of the frame body 1, and a height-adjustable inflatable fixing device arranged at the upper end of the conveyor belt 2, and the height-adjustable inflatable fixing device Including the hydraulic rod 3 arranged symmetrically front and rear, the first cross bar 4 and the second cross bar 5 respectively fixedly connected with the lower ends of the two hydraulic rods 3 are arranged at the lower ends of the first cross bar 4 and the second cross bar 5 sequentially from left to right The "U" shaped bar 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com