Automatic production line of power distribution cabinet and control method thereof

A technology for automatic production lines and power distribution cabinets, which is applied to conveyor control devices, electrical components, conveyor objects, etc., and can solve the problems of high labor intensity and low assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

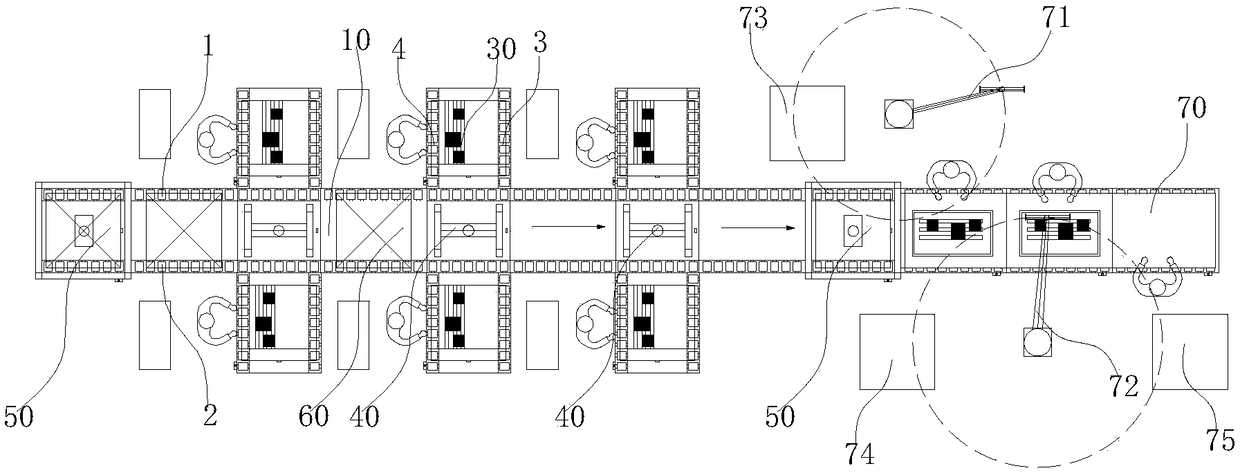

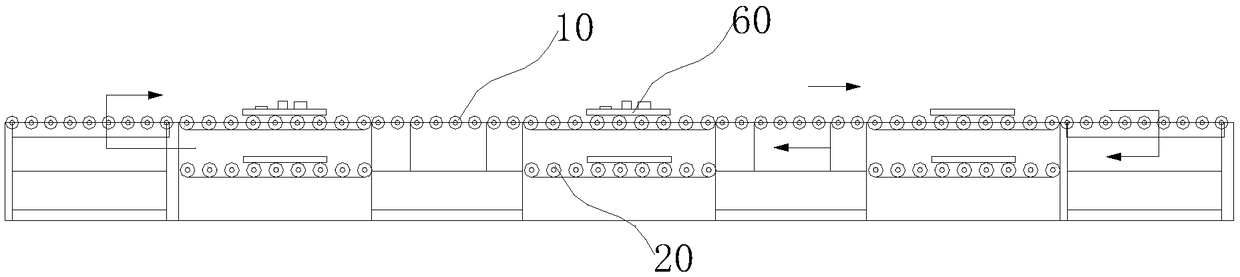

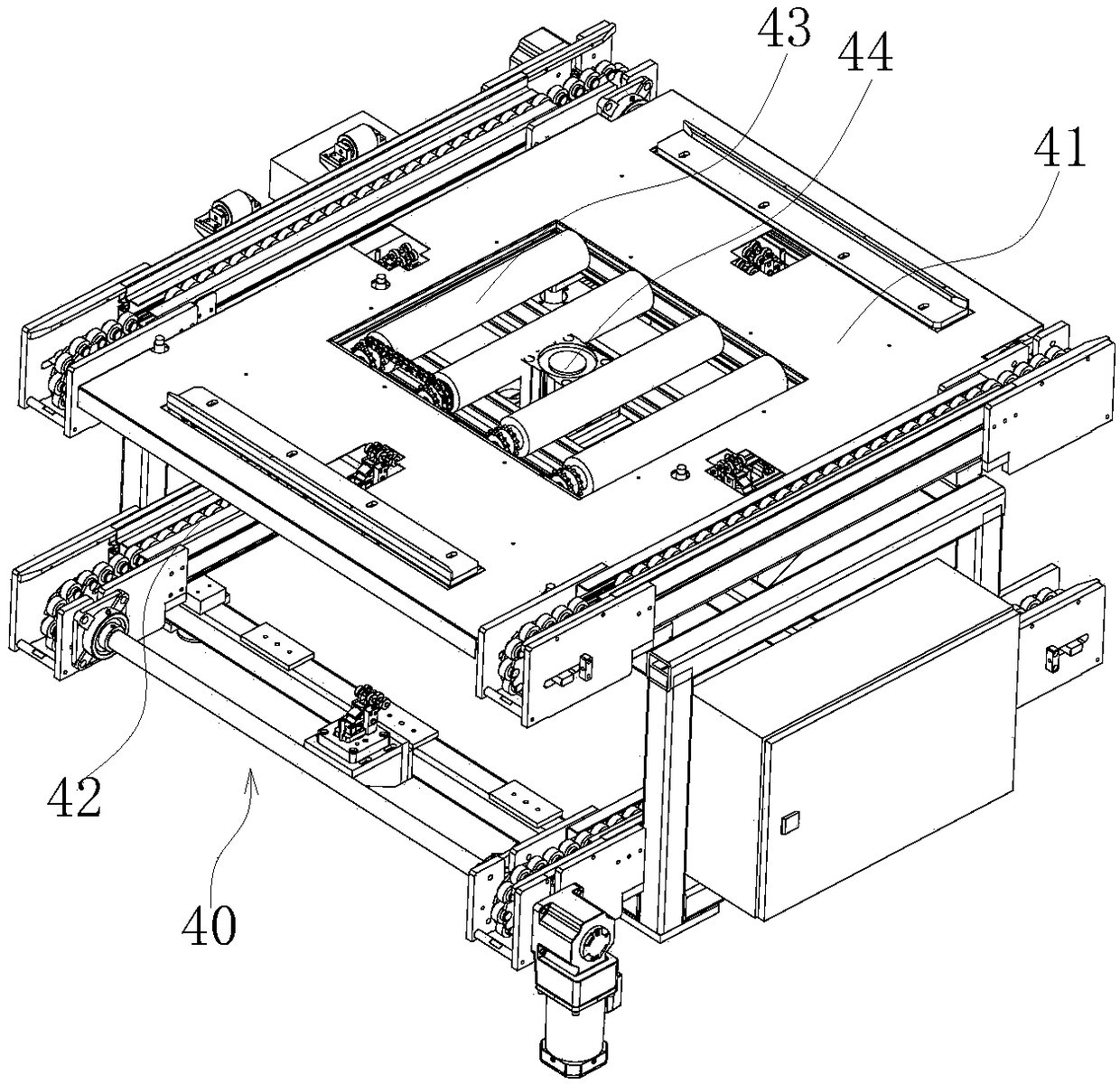

[0018] combine Figure 1~4 The present invention is further described:

[0019] An automatic production line for power distribution cabinets, including upper and lower conveying lines 10 and 20 arranged at intervals in parallel and with opposite driving directions. An operation table 30 is symmetrically arranged on both sides of the driving direction of the upper conveying line 20 and the upper conveying line 10 A transfer table 40 between two symmetrical operation tables 30 is arranged on the top, and the operation table 30 is higher than the upper conveying line 10. The transfer table 40 includes a first drive device for driving the transfer table 40 to move up and down and a The first conveying device in which the transmission direction of the upper conveying line 10 is vertical, and the two ends of the transmission directions of the upper and lower conveying lines 10 and 20 are all arranged with lifting platforms 50, and the described lifting platform 50 includes driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com