A new type of beer brewing machine

A beer and a new type of technology, applied in the field of new beer brewing machines, can solve the problems of strong operation specialization, high consumption of wine pressurization system, complex structure, etc., and achieves low production process requirements, high cost acceptability, and high cost. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

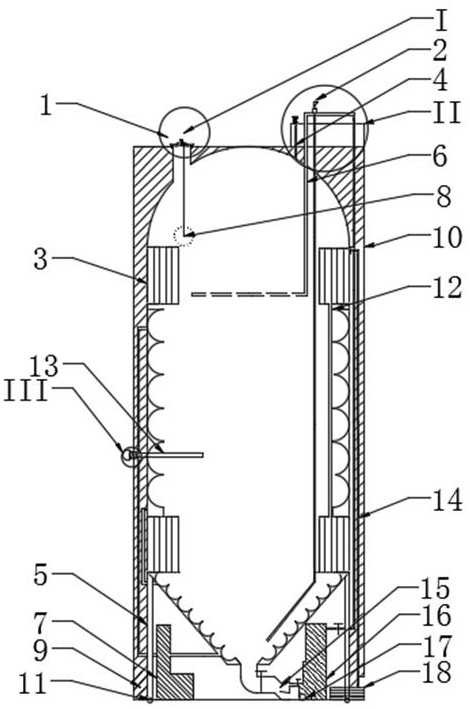

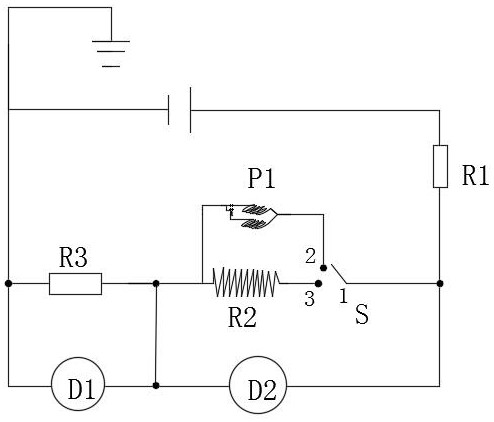

[0036] Such as figure 1 As shown, in this embodiment, a new type of beer brewing machine includes a tank body with a fermentation chamber for producing beer, a sealable feeding port arranged on the tank body and used for adding materials to the fermentation chamber, A wine dispensing system installed in the fermentation chamber for taking out beer, said fermentation chamber is provided with a built-in airbag 3 in a compressed state, and said built-in airbag 3 communicates with a pressurization system capable of pressurizing the built-in airbag 3 .

[0037] When brewing beer, the material is fermented in the fermentation chamber, and the feeding port is provided with a sealing structure 1 for the feeding hole, so that the fermentation chamber is in a sealed state. By inflating or exhausting the built-in airbag 3 to change the volume of the built-in airbag 3, the air pressure in the fermentation chamber can be controlled, and no additional gas is needed to maintain the pressure...

Embodiment 2

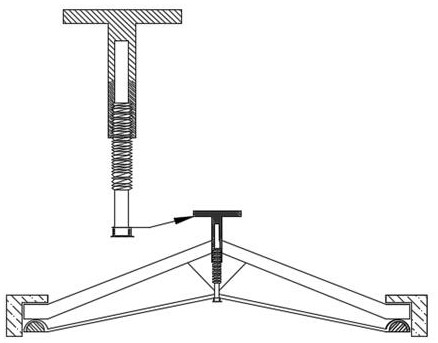

[0041] On the basis of the above-mentioned embodiments, in this embodiment, the pressurization system includes a pressurization structure 18 arranged in the tank body and an airbag connection arranged in the tank body and communicating between the pressurization structure 18 and the built-in airbag 3 Tube 14. The described supercharging structure 18 adopts a foot valve or an air pump.

[0042] The use of the foot valve is easy to use. When it is necessary to increase the volume of the built-in air bag 3, the air can be blown into the built-in air bag 3 by stepping on the foot valve, and it is convenient to regulate the speed of the volume change of the built-in air bag 3, which is beneficial in critical Points to achieve fine-tuning to improve the degree of security.

[0043]The use of an air pump to blow air into the built-in air bag 3 can realize automatic or electric control, and can reduce labor intensity. In this embodiment, other contents not described are the same as ...

Embodiment 3

[0045] On the basis of the above-mentioned embodiments, in this embodiment, the fermentation chamber is arranged vertically, and the built-in airbags 3 are ring-shaped and provided with two, and the two built-in airbags 3 are arranged in the longitudinal direction of the fermentation chamber. On the inner surface of the tank body, an air bag pipeline is communicated between the two built-in air bags 3 .

[0046] Setting the fermentation chamber vertically facilitates the circulation of solid materials, and does not require additional structures to drive materials, which is conducive to reducing production costs. By using two built-in air cells 3, the range of pressure regulation can be increased. In this embodiment, other contents not described are the same as those in the foregoing embodiments, so details are not repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com