Paver or feeder vehicle with pushing device for a material handover process

A technology for refurbishment and loading of materials, applied in conveyors, road repairs, vehicle parts, etc., can solve problems such as butting of ejector rollers, increasing the risk of collision, and difficulty in maintaining a predetermined distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

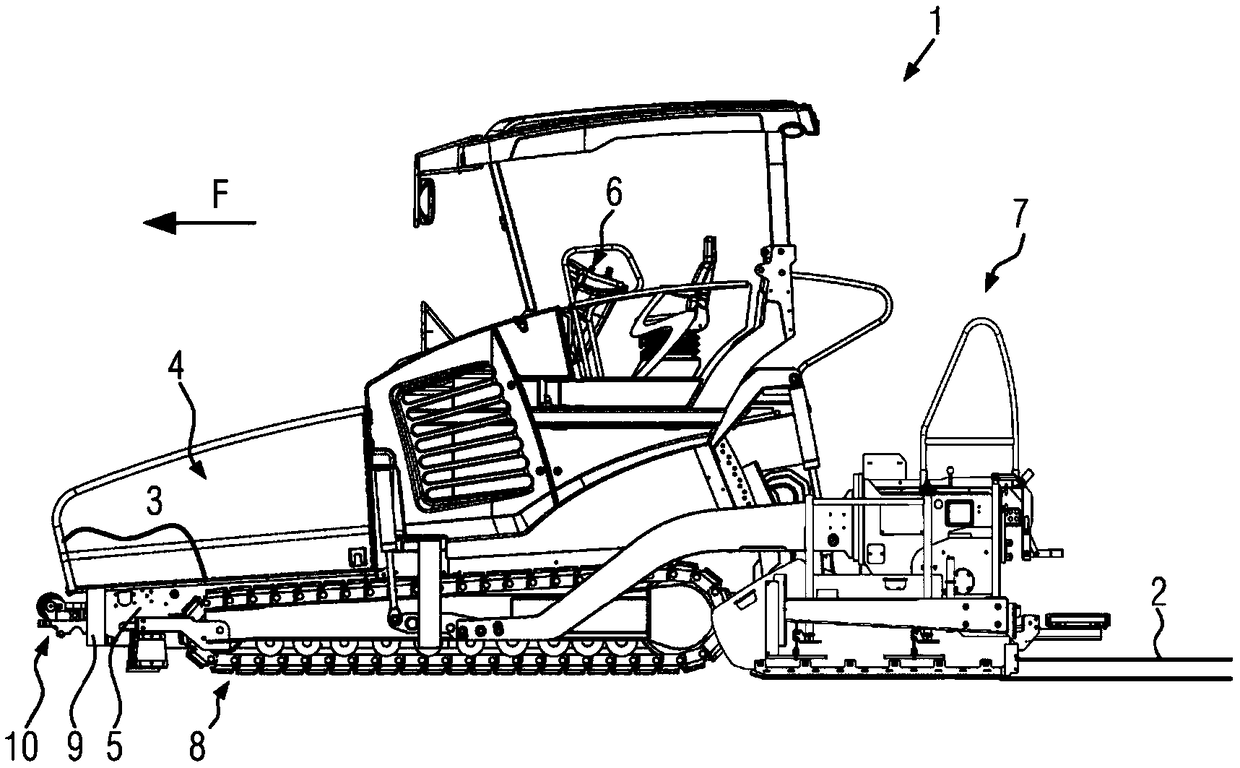

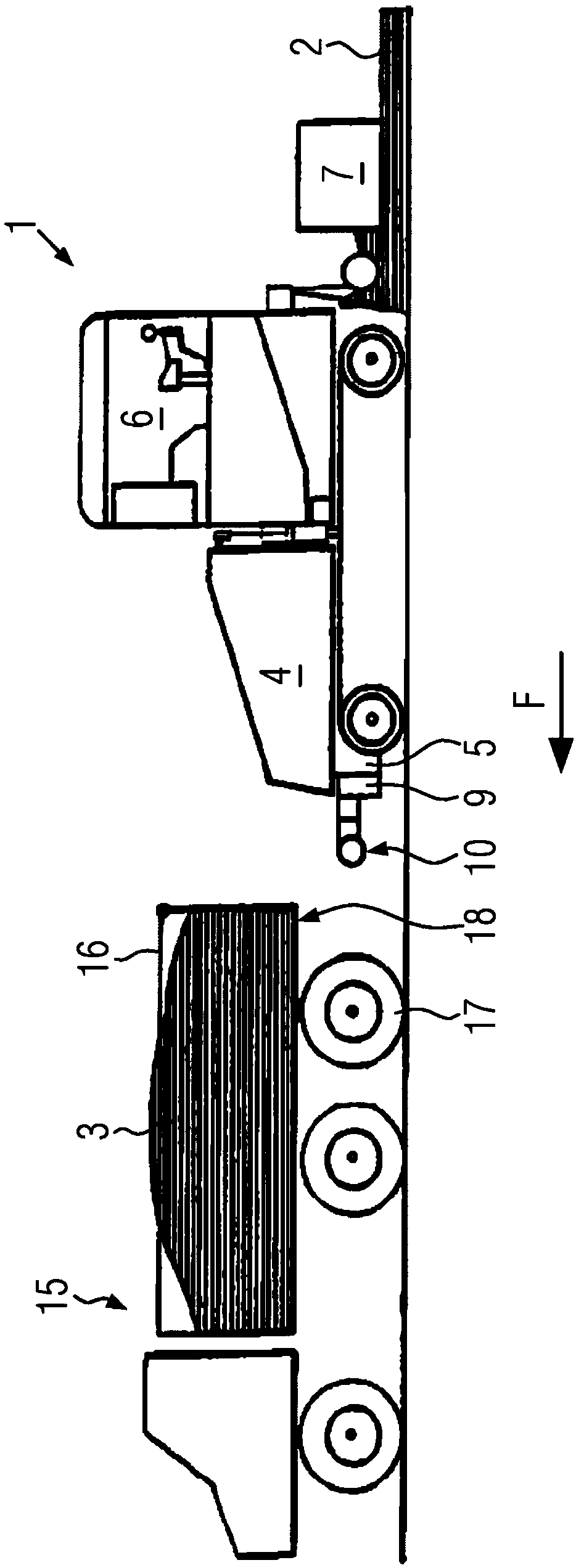

[0056] figure 1 A road making machine in the form of a road finishing machine 1 for producing paved layers 2 is shown. The road finishing machine 1 comprises a material hopper 4 in which paving material 3 for producing a paving layer 2 is stored. As viewed in the direction of travel F, the material hopper 4 is arranged at the front on the chassis 5 of the road finishing machine 1 . The road finishing machine 1 also comprises a control platform 6 from which an operator can control the road finishing machine 1 . Arranged behind the road finishing machine 1 , as viewed in the direction of travel F, is a movable screed 7 with which the road finishing machine 1 processes the pavement material 3 into a new paving layer 2 . For this purpose, the paving material 3 stored at the front in the material hopper 4 is conveyed to the rear by means of a longitudinal conveying device, not shown, counter to the direction of travel F, spread in front of the screed 7 and finally compacted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com