Concrete square column formwork

A concrete and formwork technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of lax formwork joints, difficult to control the corner radian, and complex formwork assembly process. Improve work efficiency, simplify the assembly process, and avoid the effect of dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

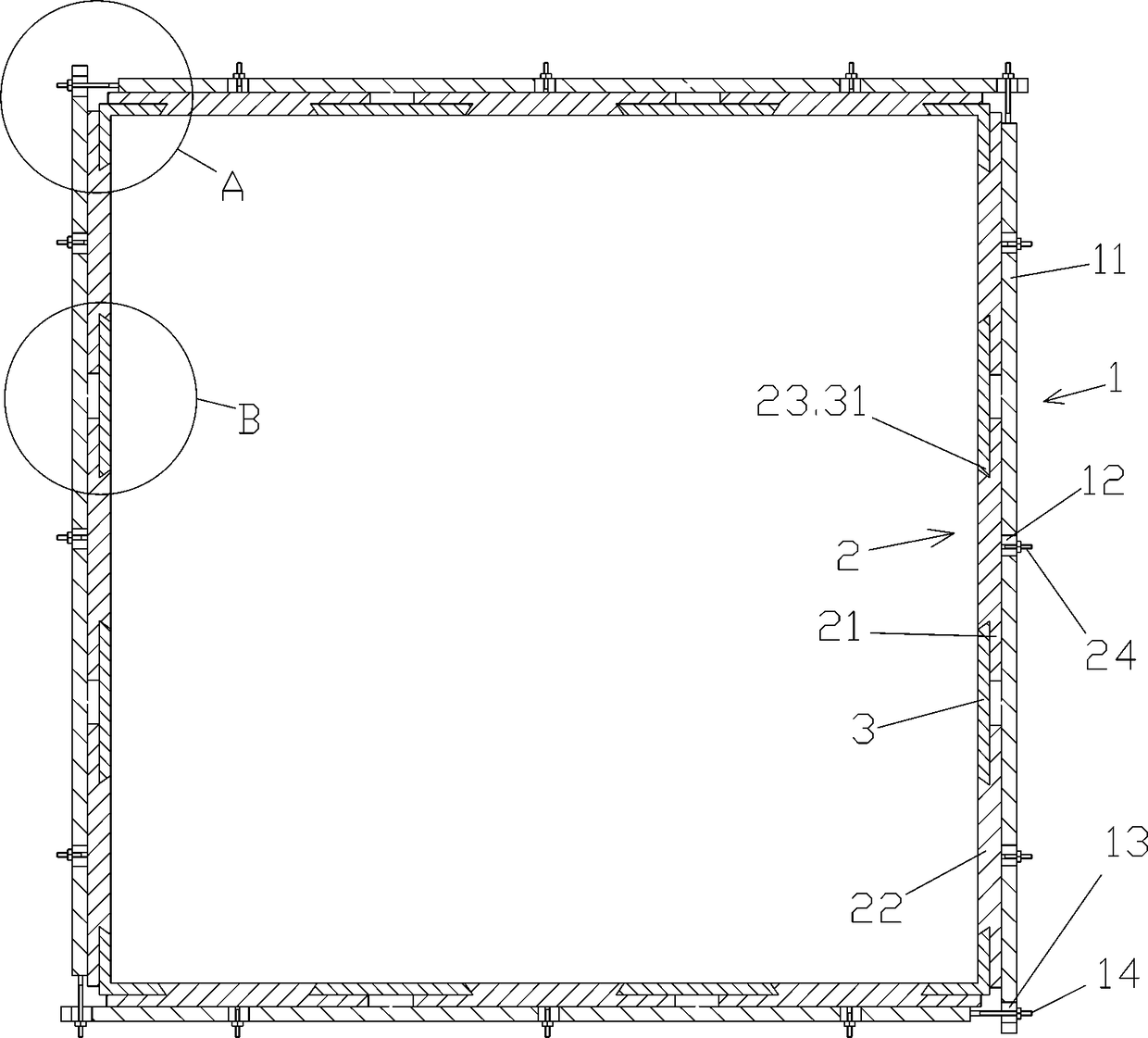

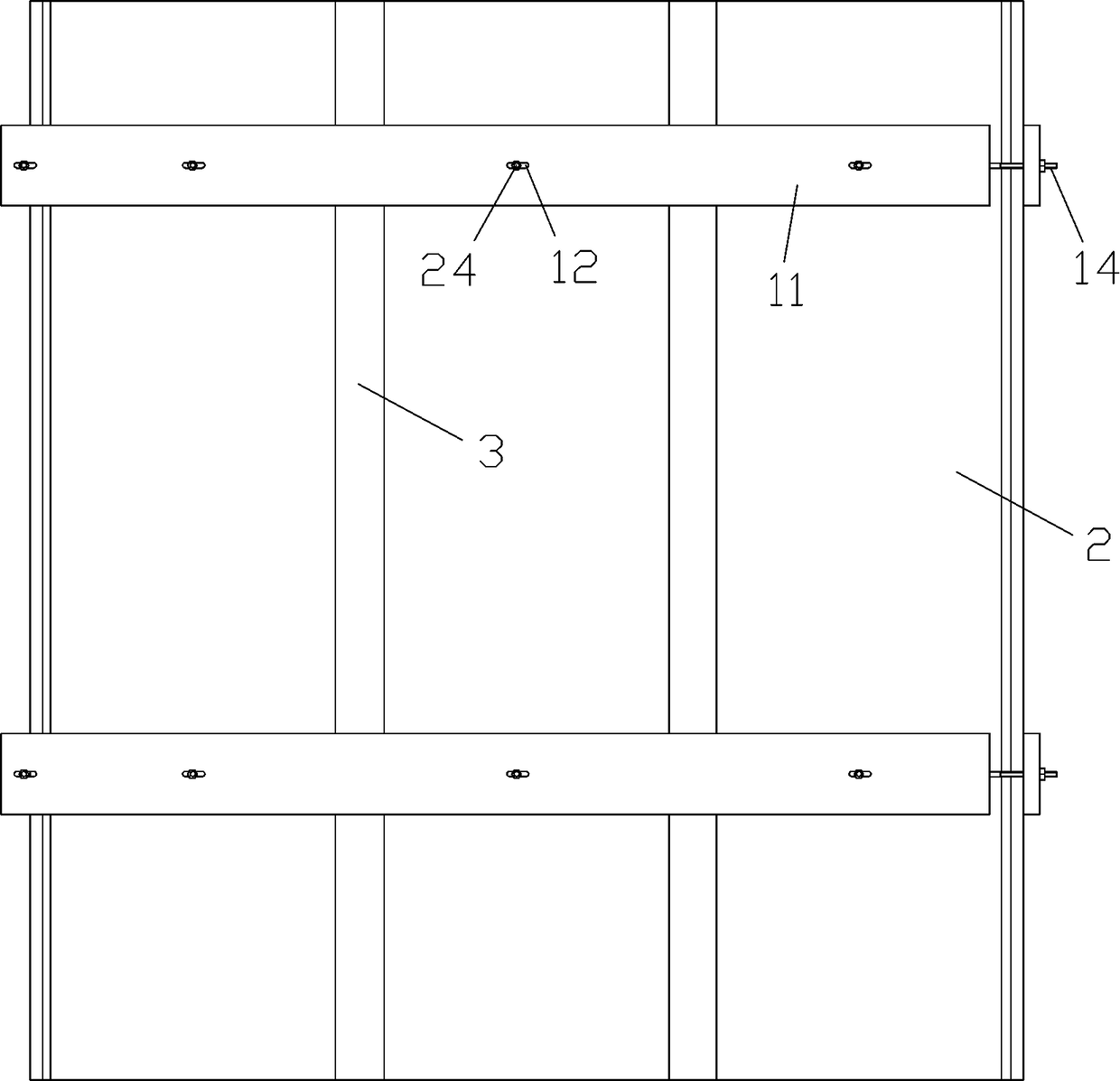

[0016] like Figures 1 to 4 As shown, a concrete square column formwork includes a square tube structure surrounded by a plurality of formworks 2, two adjacent formworks 2 in the square tube structure are connected by a plug-in plate 3, and there are many square tube structure jackets. a pressing mechanism 1;

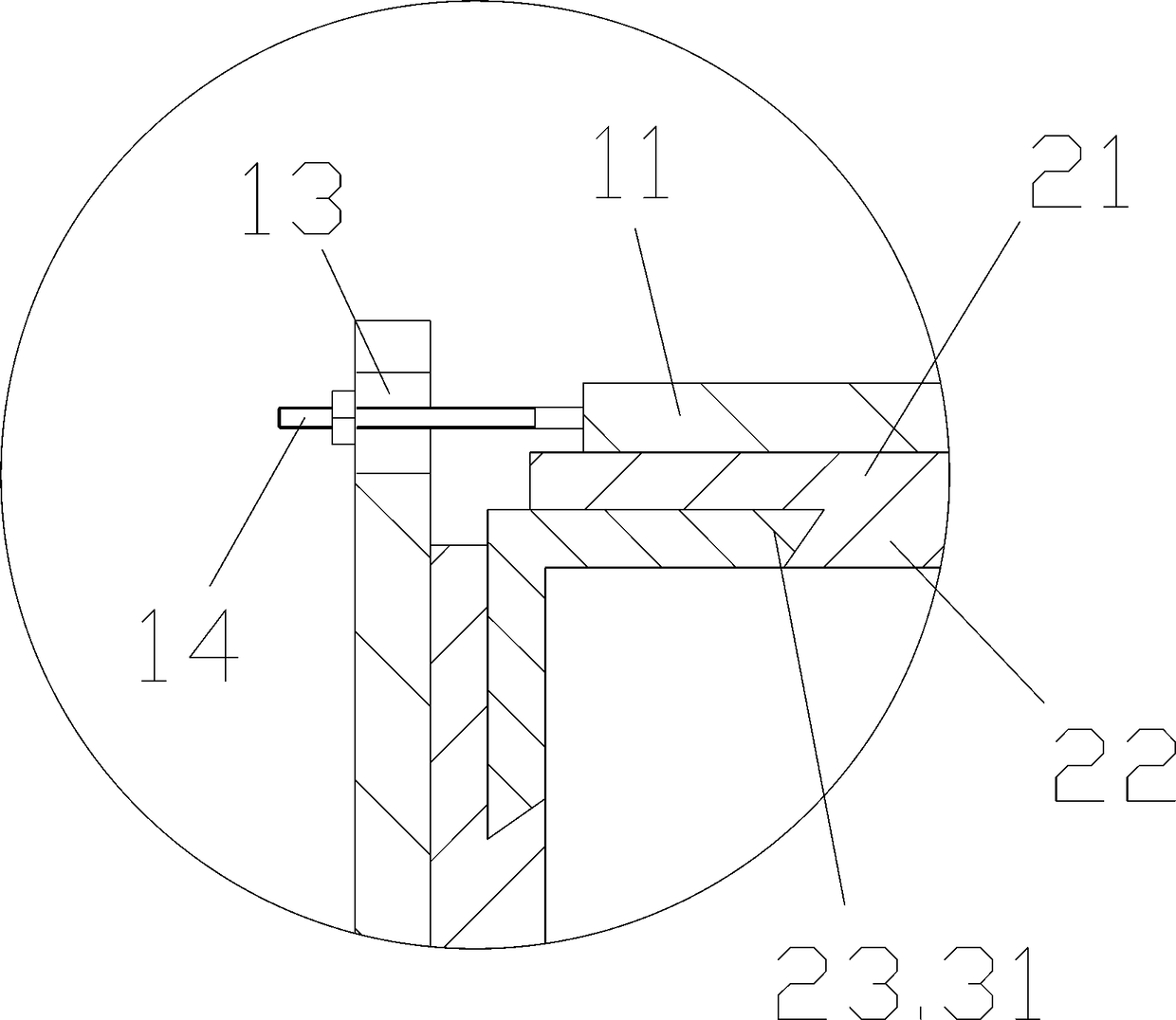

[0017] The template 2 includes a bottom plate 21, a section of boss 22 extends from the middle of the bottom plate 21, a triangular cutout 23 is provided on both sides of the boss 22, and a plurality of first a screw 24;

[0018] Both ends of the inserting plate 3 have a wedge-shaped convex edge 31, the four inserting plates 3 at the corners in the square tube structure are rectangular, and the other inserting plates 3 are flat;

[0019] When the rib 31 of the board 3 is inserted into the slot 23 of the formwork 2, the end surface of the bottom plate 21 is close to the end surface of the board 3;

[0020] The pressing mechanism 1 is formed into a frame structure surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com