Motor with good sealing performance

A technology of sealing performance and motor body, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the normal running of electric vehicles, poor sealing effect, easy to burn out motors, etc., to achieve reliable functions and easy replacement. , The effect of simple installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

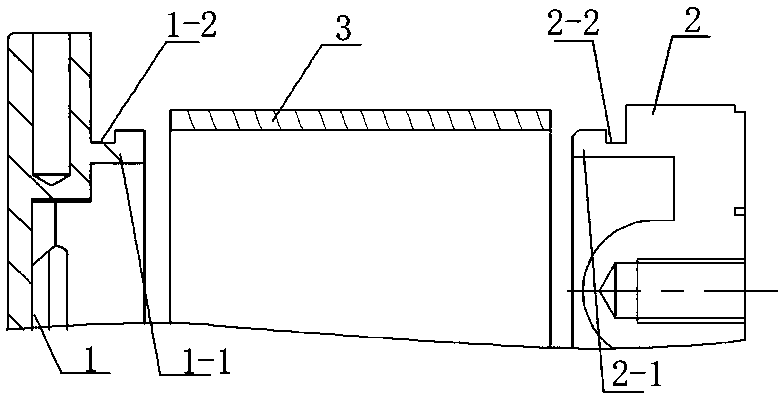

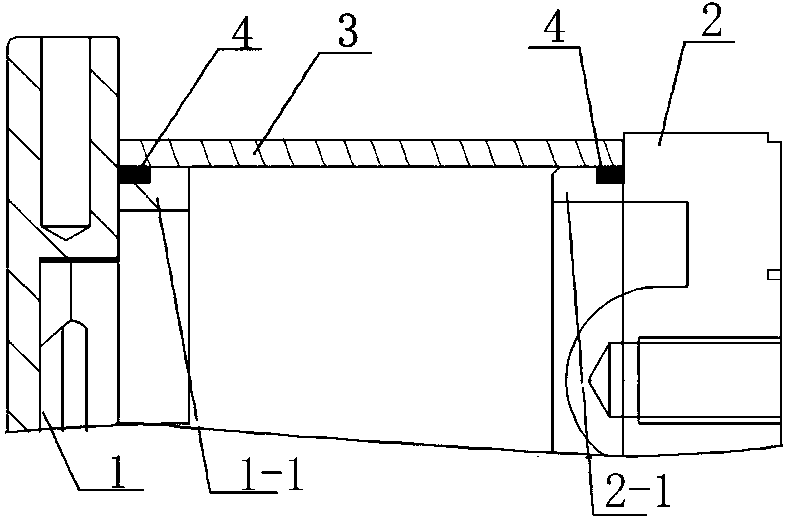

[0009] Such as figure 1 As shown, a motor with good sealing performance includes a motor body 3, a connecting plate 2 and an end cover 1; the connecting plate 2 and the end cover 1 are respectively provided with notches 2-1, 1-1 and the motor body 3, the barrel connection of the middle connecting plate 2 and the spigot 1-2, 1-1 of the end cover 1 are respectively provided with a circle of grooves 1-3, 2-3 on the outside of the root, which is used to install the O-ring 4; After the end cover 1 and the connecting plate 2 are installed with the machine barrel 3, the mouth of the machine barrel 3 is engaged with the outside of the O-ring 4 to play a sealing role.

[0010] The thickness of the O-ring 4 is not less than the depth of the grooves 1-3, 2-3 in order to achieve a good sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com