A method for producing tube tops from waste trousers

A technology of trousers and waste, which is applied in the field of clothing design, can solve the problems of lack of remodeling, etc., and achieve the effects of environmental protection, simple operation, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

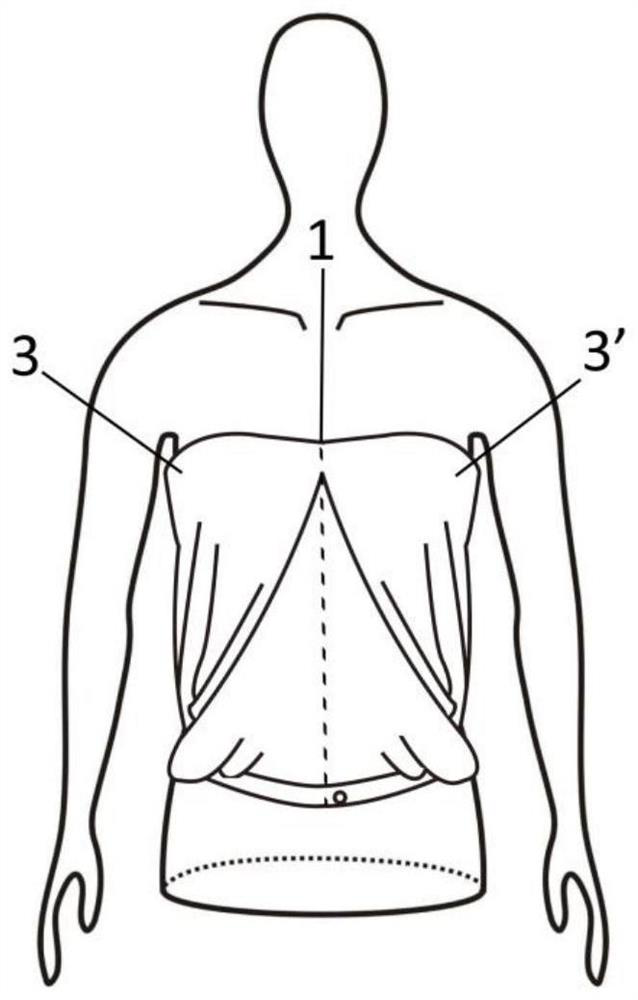

[0031] A method for producing tube tops from waste trousers The specific steps are as follows:

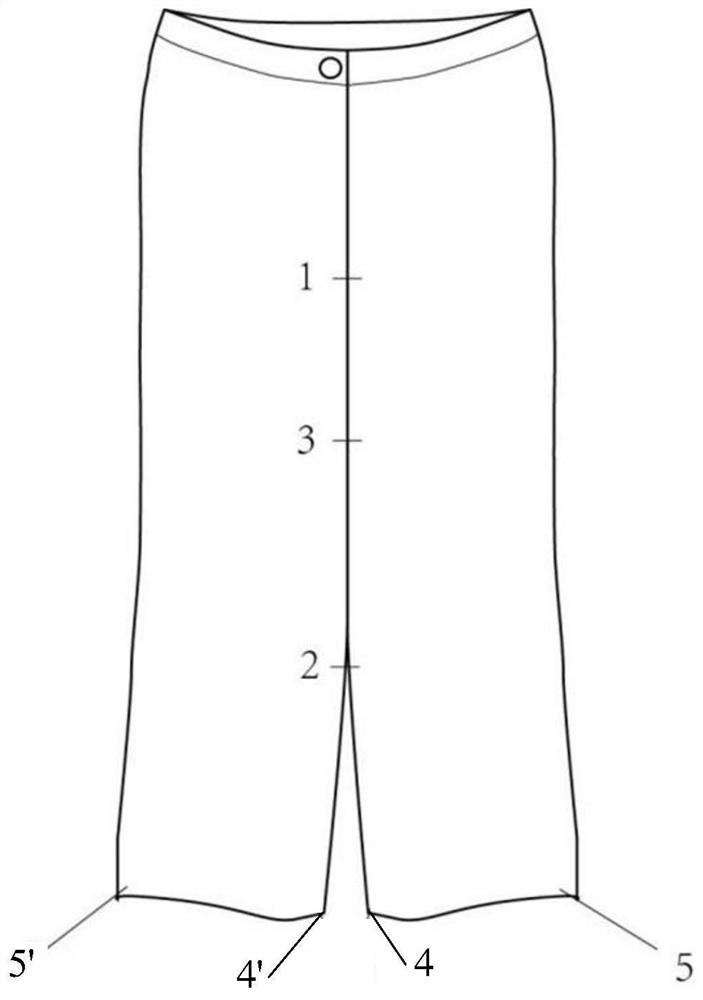

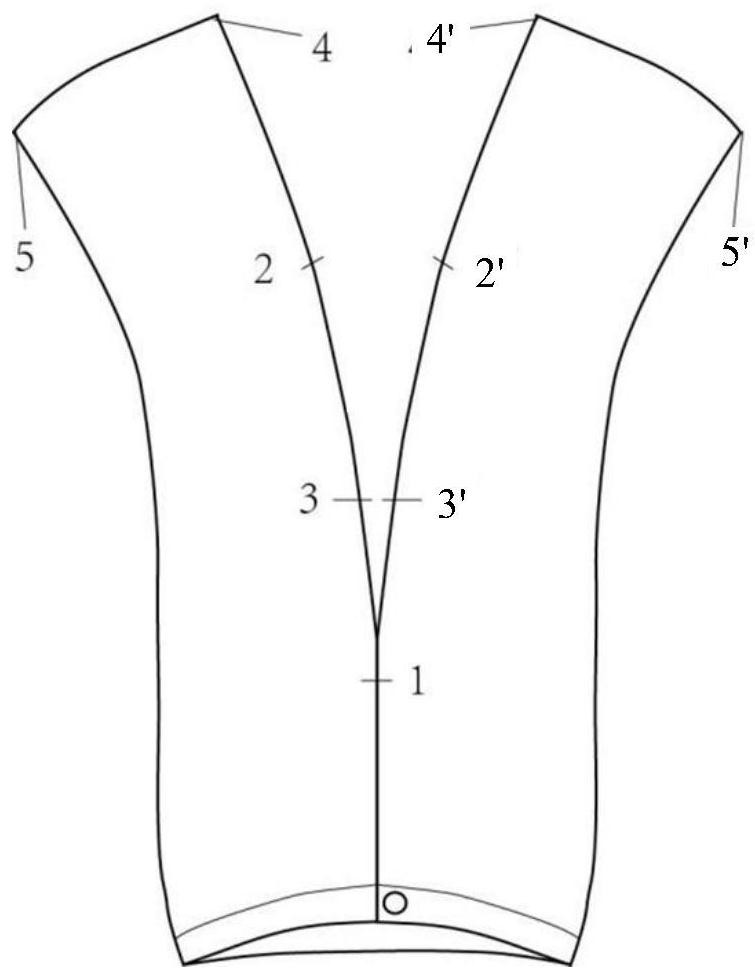

[0032] Step 1, such as figure 1 and 2 As shown, define the crotch 1, left thigh inner part 3, left calf inner part 2, left trouser leg opening inner part 4, left trouser leg opening outer part 5, right thigh inner part 3', right calf inner part 2 of waste trousers ', the inner part of the right trouser leg opening 4' and the outer part of the right trouser leg opening 5'. The inner part of the left thigh 3, the inner part of the left calf 2, and the inner part 4 of the left trouser leg are arranged in sequence along the inner seam of the left trouser leg. The inner part of the right thigh 3', the inner part of the right calf 2' and the inner part of the right trouser leg opening 4' are arranged in sequence along the inner seam of the right trouser leg.

[0033] Take a pair of old trousers, disassemble the seam of the inner side of the left trouser leg between the crotch 1 and th...

Embodiment 2

[0041] Step 1, such as figure 1 and 2 As shown, define the crotch 1, left thigh inner part 3, left calf inner part 2, left trouser leg opening inner part 4, left trouser leg opening outer part 5, right thigh inner part 3', right calf inner part 2 of waste trousers ', the inner part of the right trouser leg opening 4' and the outer part of the right trouser leg opening 5'. The inner part of the left thigh 3, the inner part of the left calf 2, and the inner part 4 of the left trouser leg are arranged in sequence along the inner seam of the left trouser leg. The inner part of the right thigh 3', the inner part of the right calf 2' and the inner part of the right trouser leg opening 4' are arranged in sequence along the inner seam of the right trouser leg.

[0042] Take a pair of old trousers, disassemble the seam of the inner side of the left trouser leg between the crotch 1 and the inner part of the left calf 2', and sew the inner side of the left trouser leg between the crotc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com