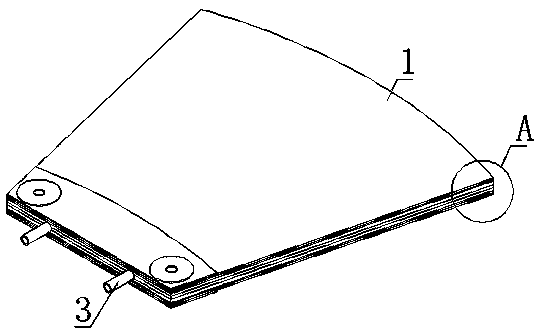

Multi-layer composite ceramic filter plate with double water channels and preparation method of multi-layer composite ceramic filter plate

A ceramic filter plate, multi-layer composite technology, used in ceramic products, filtration separation, membrane filters, etc., can solve the problems of uneven bonding and pressing force, increase drainage resistance, affect filtration and separation, etc. Uniform density, reduced waste and loss, improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a dual-channel multilayer composite ceramic filter plate, the steps comprising: (1) ingredients: corundum: potassium feldspar: kaolin: water: adhesive: dispersant according to 400:100:30:200:2 : 1 ratio is formulated as the slurry of slurry A, slurry B and slurry C, wherein the corundum particle size increases successively in the batching of slurry A, slurry B and slurry C, and in the batching of slurry A The particle size of corundum is 180 mesh, the particle size of corundum in the ingredients of slurry B is 150 mesh, and the particle size of corundum in slurry C is 80 mesh;

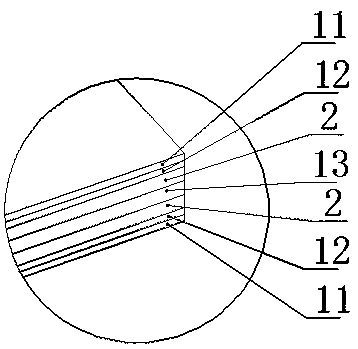

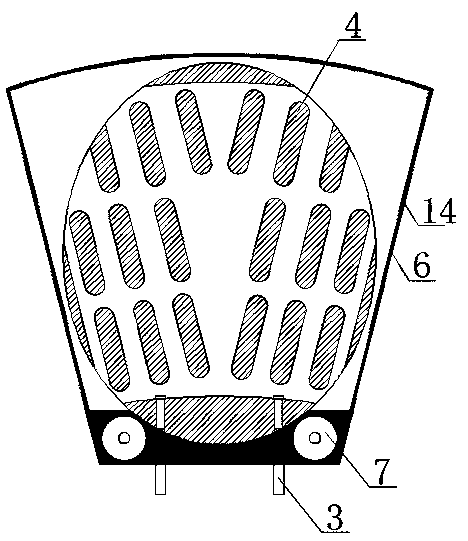

[0039] (2) Substrate production: add slurry A into the mold to form filter layer A, add slurry B after drying to form filter layer B, then put in water channel mold 5 complementary to the shape of water channel layer 2, and press the water channel mold into it with a press frame Slurry B fills the hollow of water channel mold 5 with slurry B, then adds slurry C to form fil...

Embodiment 2

[0045] A method for preparing a dual-channel multilayer composite ceramic filter plate, the steps comprising: (1) ingredients: corundum: potassium feldspar: kaolin: water: adhesive: dispersant according to 450:100:25:250:1 : 1 ratio is formulated as the slurry of slurry A, slurry B and slurry C, wherein the corundum particle size increases successively in the batching of slurry A, slurry B and slurry C, and in the batching of slurry A The particle size of corundum is 180 mesh, the particle size of corundum in the ingredients of slurry B is 150 mesh, and the particle size of corundum in slurry C is 80 mesh;

[0046] (2) Substrate production: add slurry A into the mold to form filter layer A, add slurry B after drying to form filter layer B, then put in water channel mold 5 complementary to the shape of water channel layer 2, and press the water channel mold into it with a press frame Slurry B fills the hollow of water channel mold 5 with slurry B, then adds slurry C to form fil...

Embodiment 3

[0052] A method for preparing a dual-channel multilayer composite ceramic filter plate, the steps comprising: (1) ingredients: corundum: potassium feldspar: kaolin: water: adhesive: dispersant according to 400:100:30:200:2 : 1 ratio is formulated as the slurry of slurry A, slurry B and slurry C, wherein the corundum particle size increases successively in the batching of slurry A, slurry B and slurry C, and in the batching of slurry A The particle size of corundum is 180 mesh, the particle size of corundum in the ingredients of slurry B is 150 mesh, and the particle size of corundum in slurry C is 80 mesh;

[0053] (2) Substrate production: add slurry A into the mold to form filter layer A, add slurry B after drying to form filter layer B, then put in water channel mold 5 complementary to the shape of water channel layer 2, and press the water channel mold into it with a press frame Slurry B fills the hollow of water channel mold 5 with slurry B, then adds slurry C to form fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com