Spark shield protection device for electromechanical cutting machine

A protective device and cutting machine technology, which is applied to the attachment of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of sparks splashing everywhere, affecting the surrounding environment, and not being able to collect sparks and dust, etc. The effect of flexibility and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

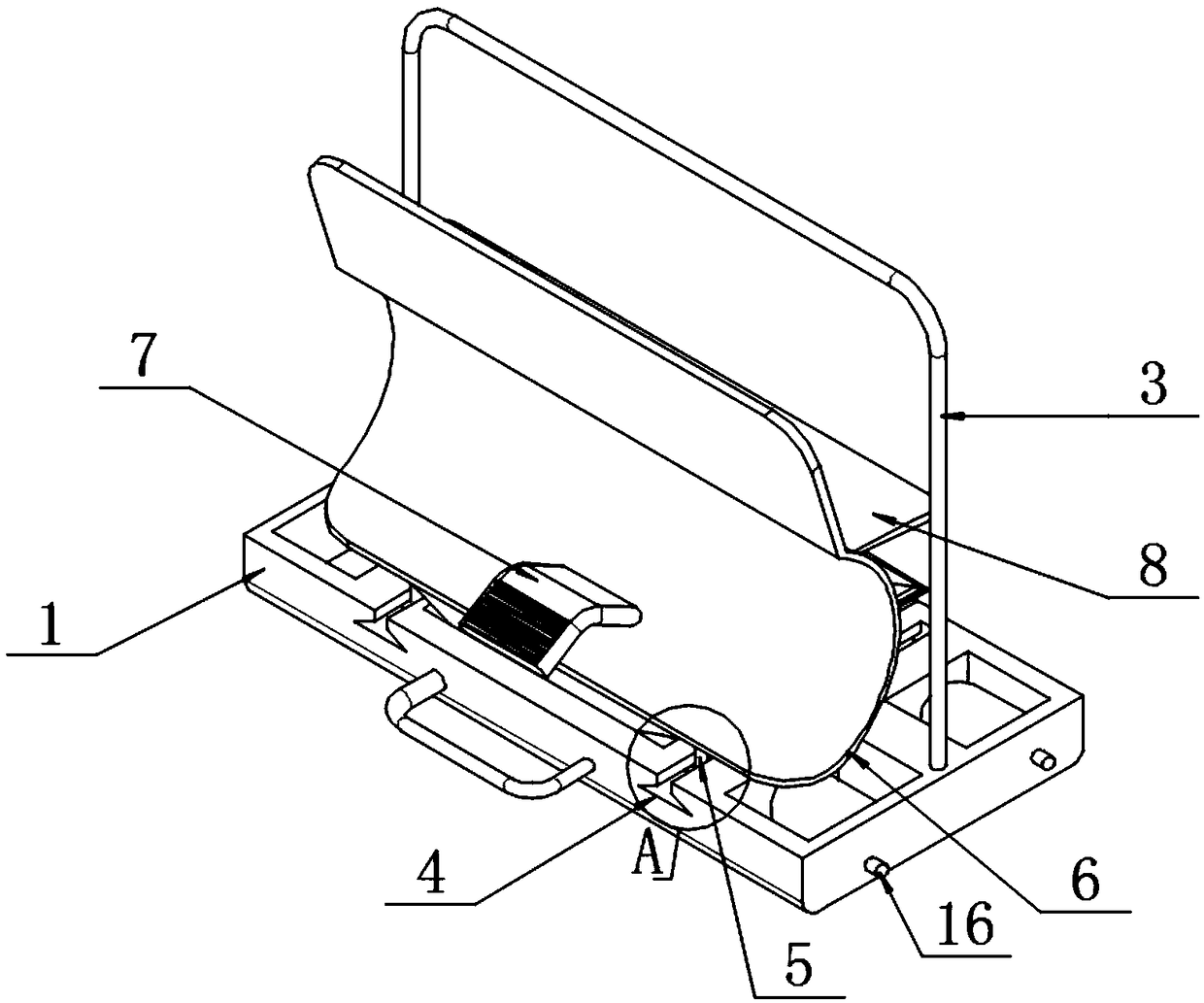

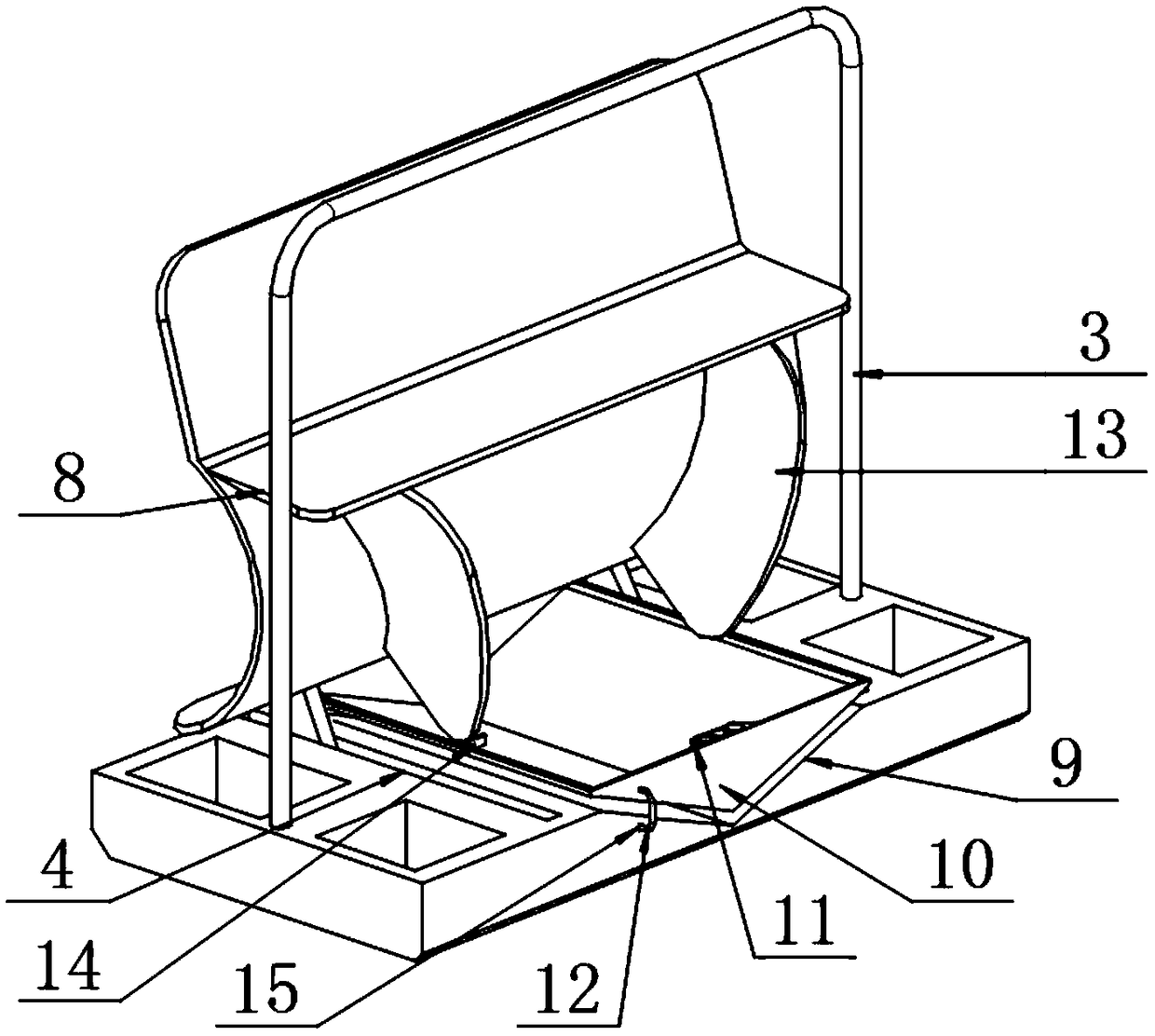

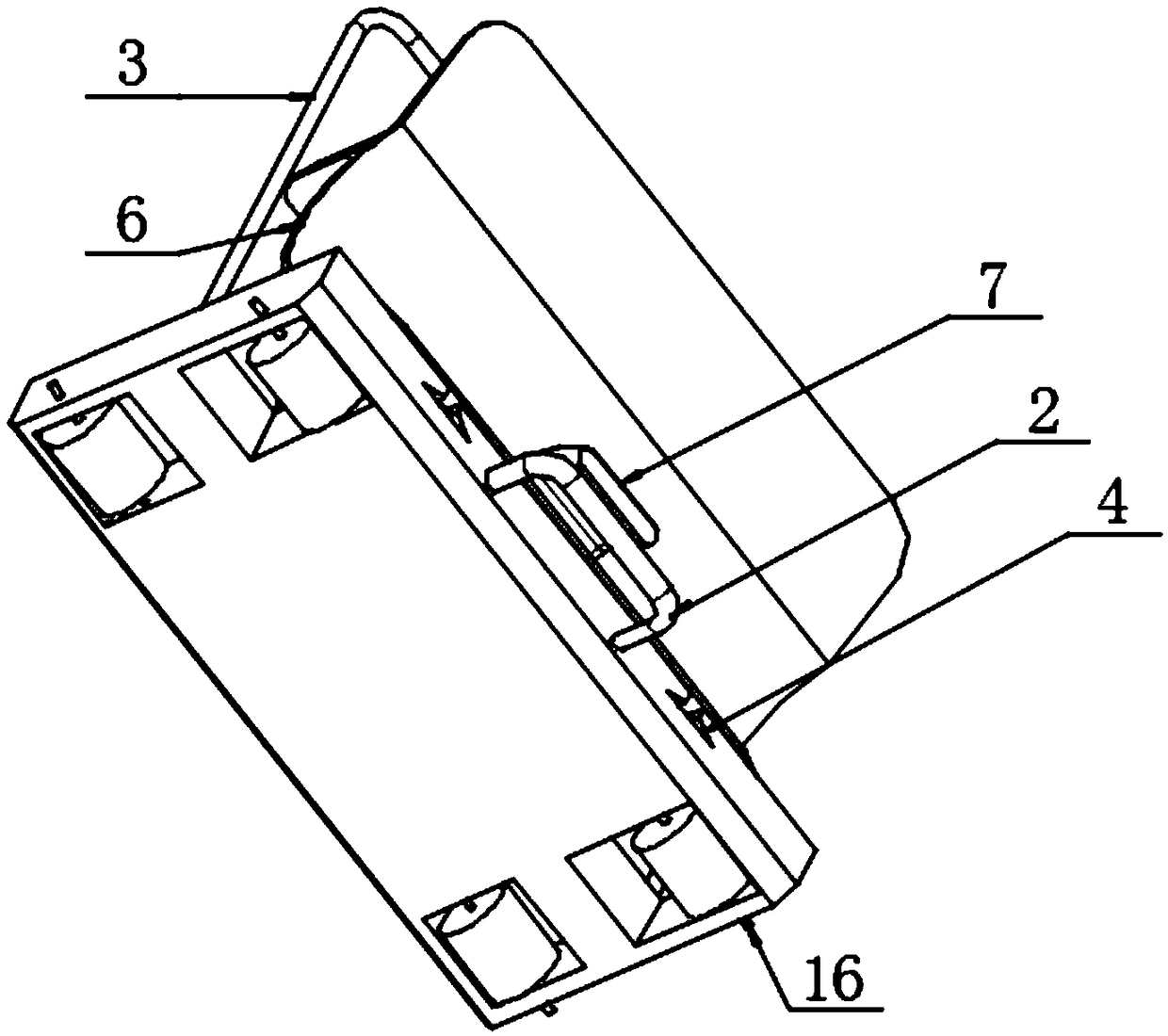

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides a spark shielding protection device for an electromechanical cutting machine, which includes: a base plate 1, a pressing handle 2, a handle 3, a first chute 4, a sliding rod 5, a protective plate 6, a pedal 7, a top Guard plate 8, placement slot 9, storage compartment 10, grip seat 11, guide rod 12, side guard plate 13, push plate 14, sliding hole 15 and rotating shaft 16; structure, and a handle 3 with a U-shaped elbow structure is vertically installed on the top surface of the base plate 1; the left and right sides of the top surface of the base plate 1 are provided with a first The chute 4, and the protective plate 6 is slidably fitted on the first chute 4 through the two left and right slide bars 5 welded at the bottom; the pedal 7 is welded on the outside of the protective plate 6 in an inclined manner, and A top guard plate 8 with a rectangular plate structure is also welded on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com