Braking system, golf cart, vehicle, braking control process

A brake system and vehicle technology, applied in the brake control process, brake system, golf cart, and vehicle fields, to achieve the effect of improving performance and safety and improving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

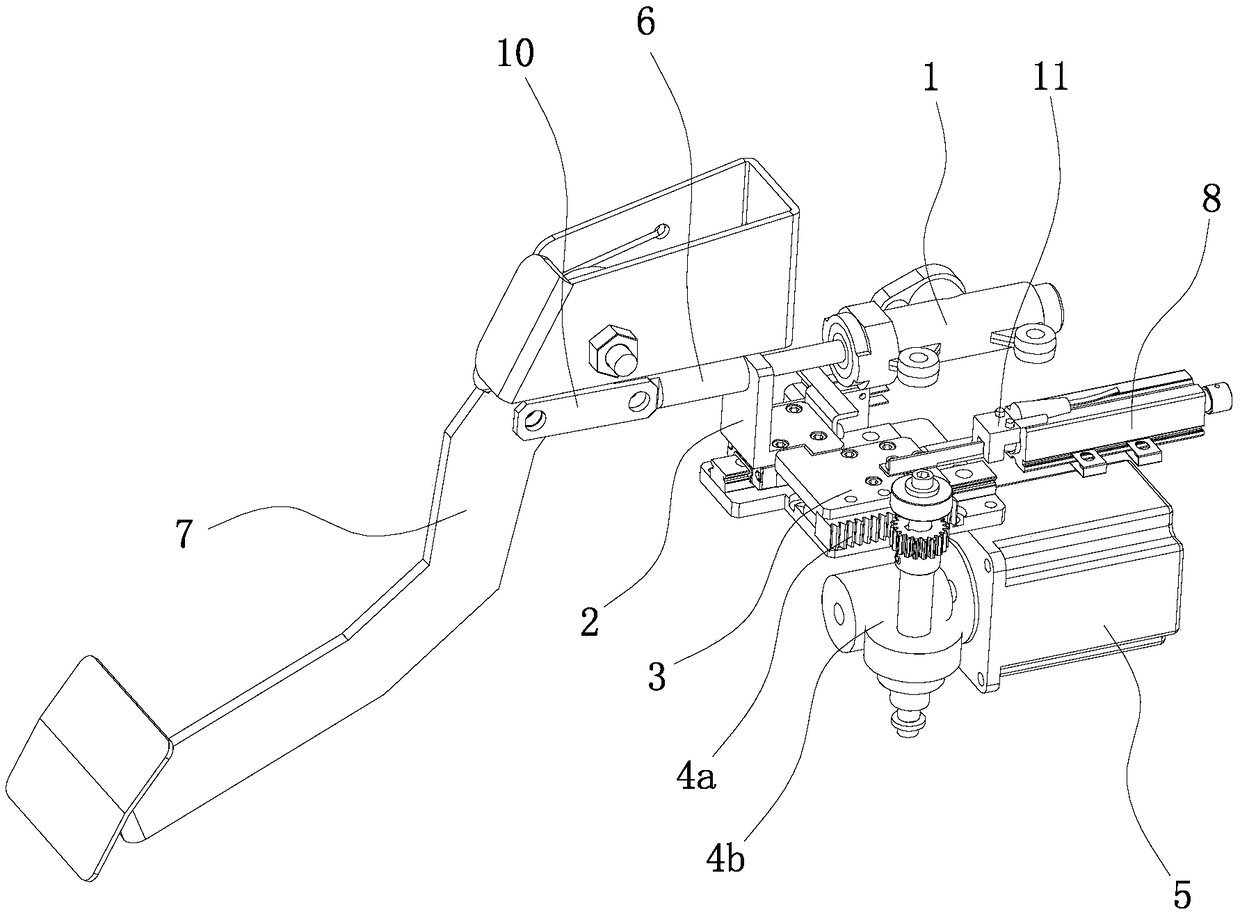

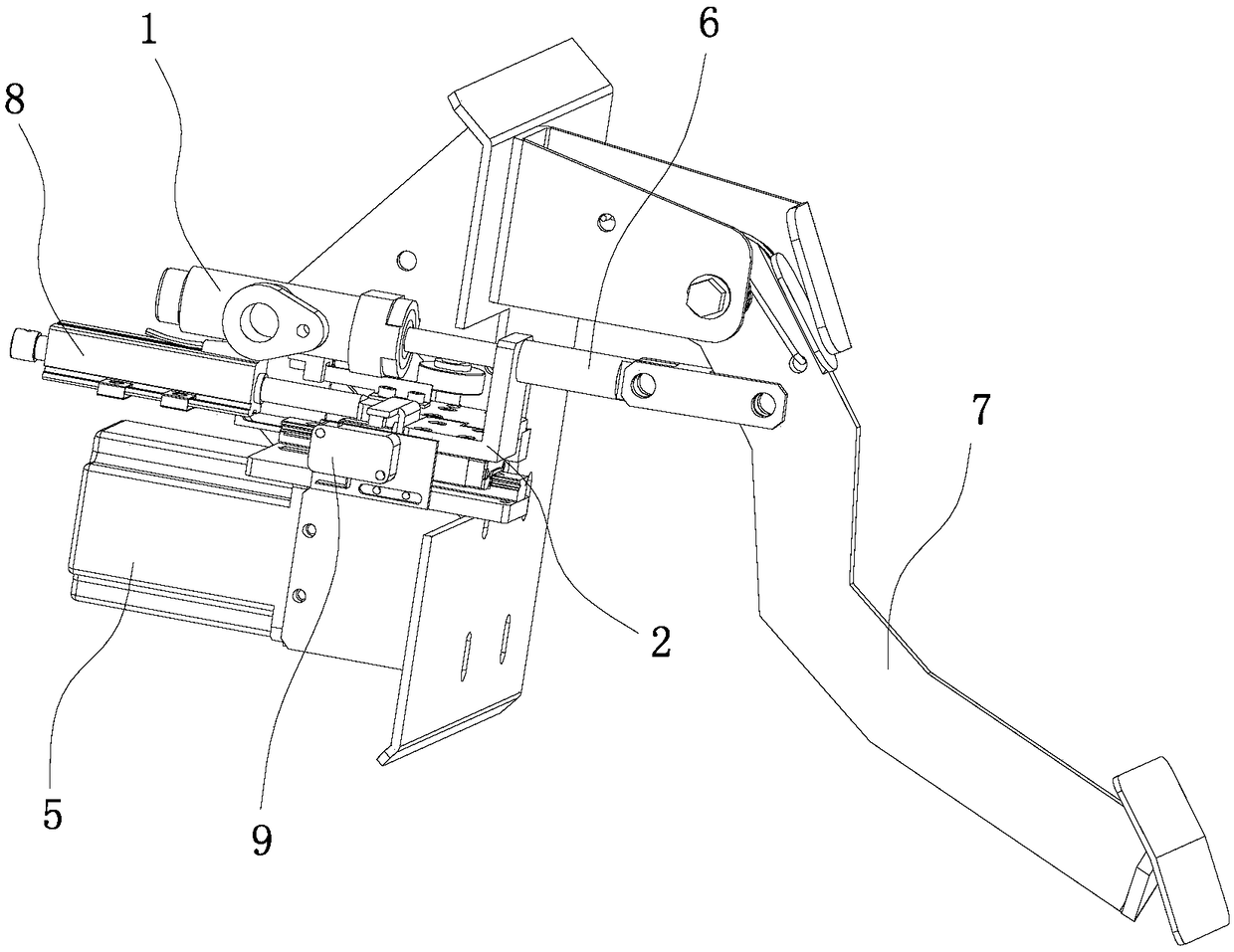

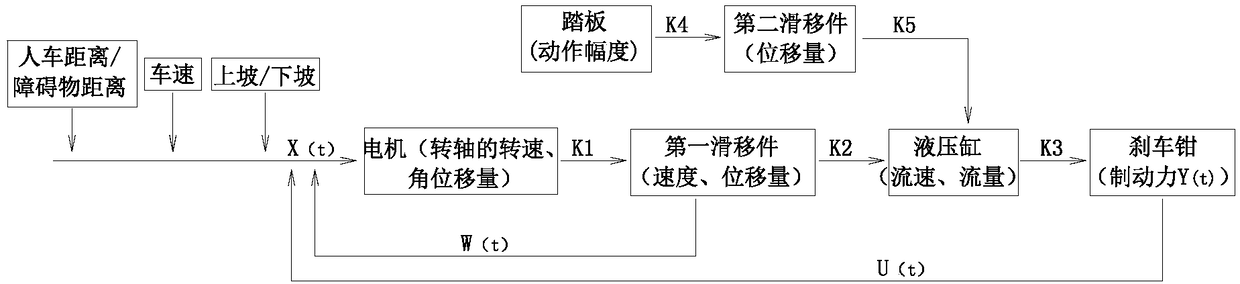

[0020] Such as figure 1 with figure 2 As shown, a braking system includes a hydraulic cylinder 1, a push block 2, a first sliding part 3, a transmission assembly, a motor 5, a second sliding part 6 and a pedal part 7; the first sliding part 3 and the second The sliding parts 6 are detachably connected to the push block 2, and the pushing block 2 is used to drive the piston rod of the hydraulic cylinder 1 to move; the pedal part 7 is connected to the second sliding part 6, and the pedal part 7 is used to pass the second sliding part 6 Push the push block 2; one end of the transmission assembly is connected to the rotating shaft of the motor 5, and the other end is connected to the first sliding member 3, and the transmission assembly is used to push the push block 2 through the first sliding member 3.

[0021] The hydraulic cylin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap