Feeding pump turbine steam source switching control method

A control method and technology for steam turbines, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as unfavorable steam source switching smoothly, and achieve the effect of avoiding water cutoff protection action, huge economic and social benefits, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

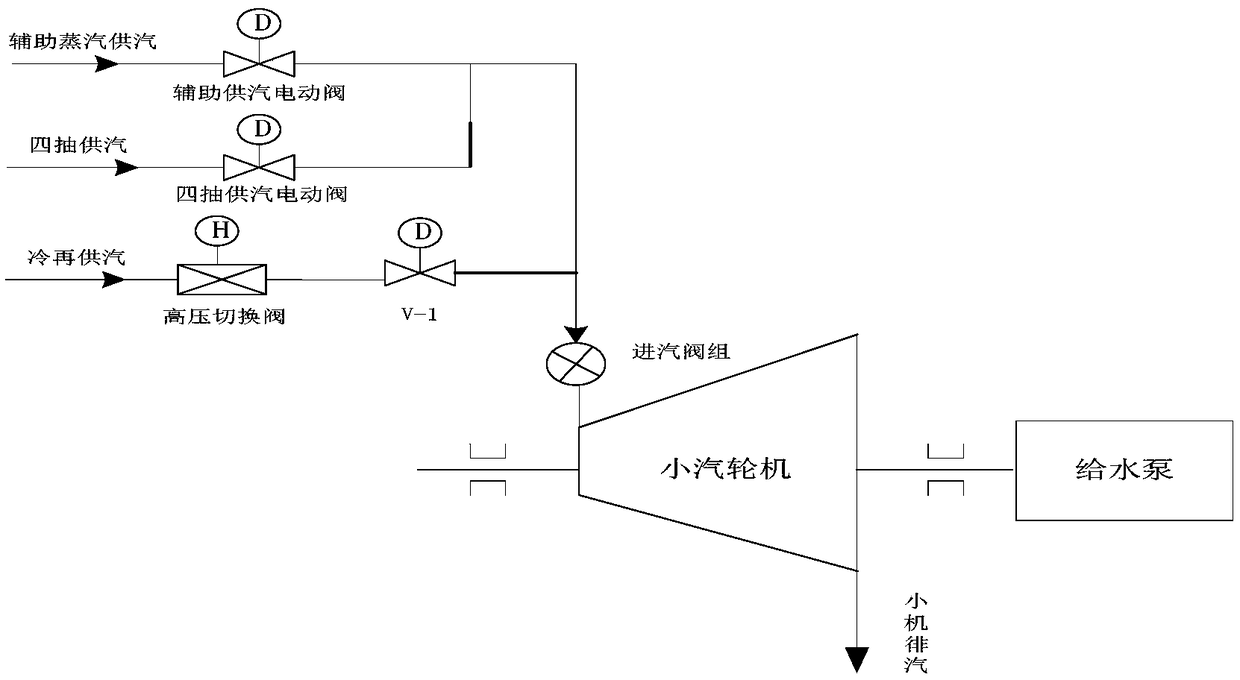

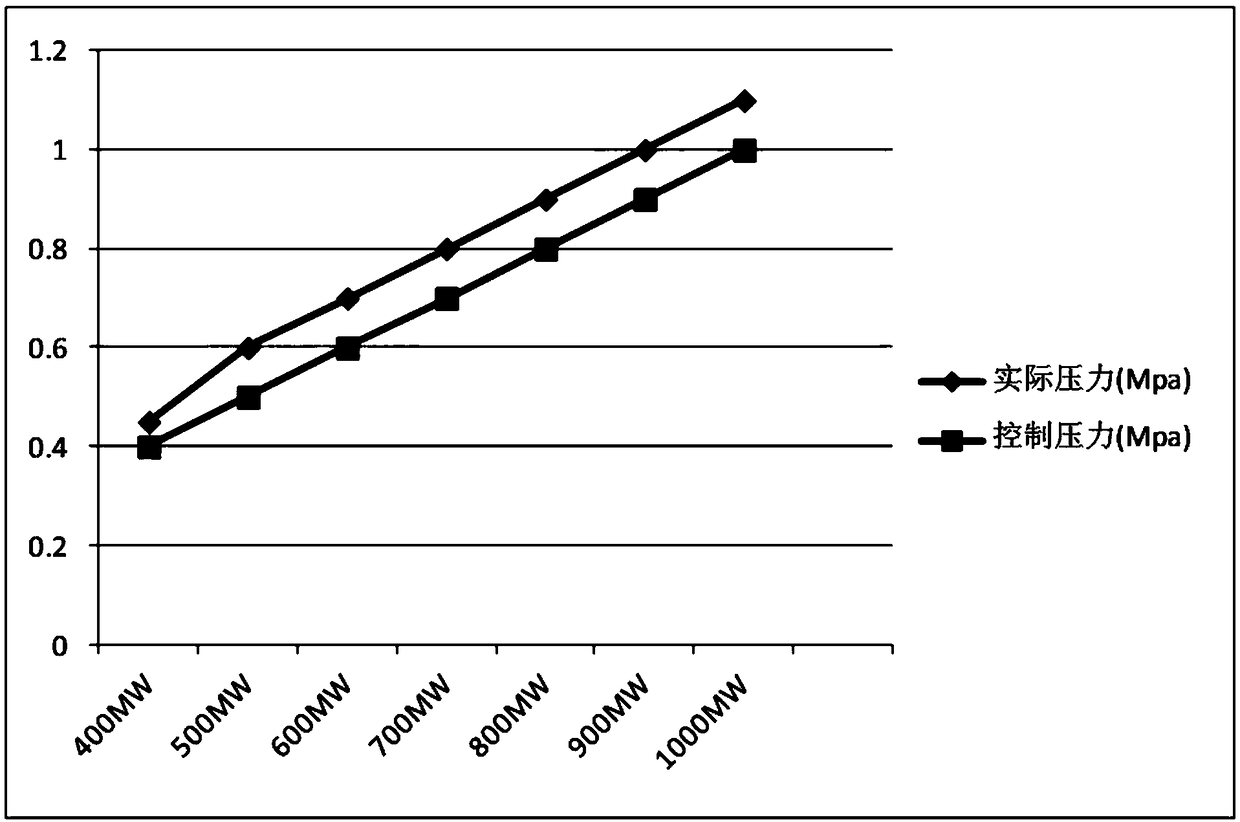

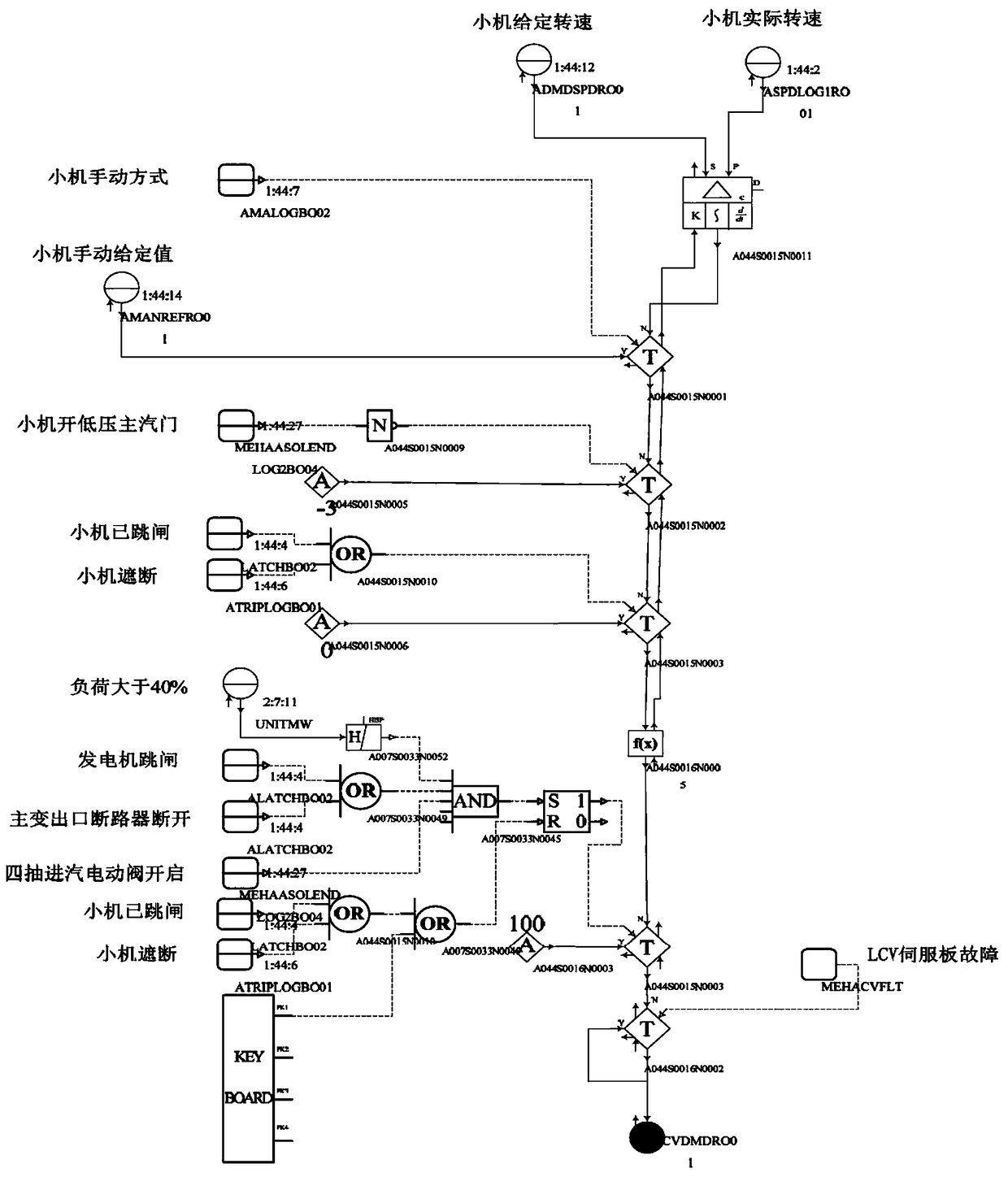

[0028] The steam source switching control method of the feed pump steam turbine in this embodiment enables the high-pressure switching valve to supply steam according to the set inlet steam pressure curve when the unit is under low load or the four-stage steam extraction system fails; in addition, when the turbine generator trips In FCB or FCB working conditions, the logic of feed pump turbine inlet steam adjustment valve and high-pressure switching valve is quickly processed. When the feed pump turbine four-exhaust steam supply is interrupted, the cold re-high pressure steam source can be quickly switched to the feed pump turbine for steam supply, and according to The boiler working condition automatically adjusts the feed water flow, maintains the stable operation of the boiler bypass system, avoids the boiler water cut-off protection action, and controls the main steam temperature within the required range to protect the safe operation of the unit equipment.

[0029] The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com