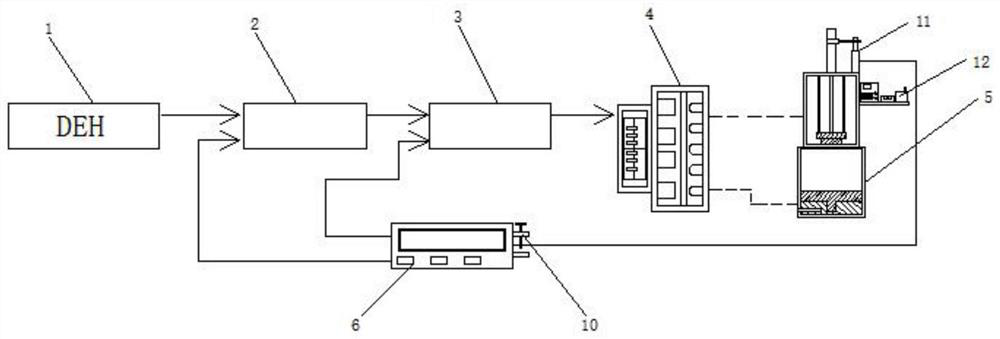

On-line replacing set steam turbine high-pressure governing valve feedback device

A speed-regulating valve and feedback device technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as short circuit of wires, difficult adjustment of valve position, inability to ensure speed-regulating valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

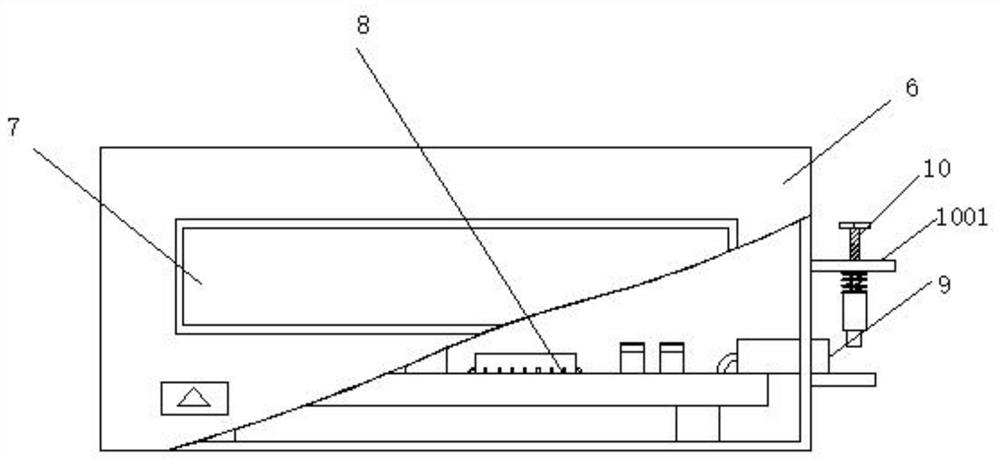

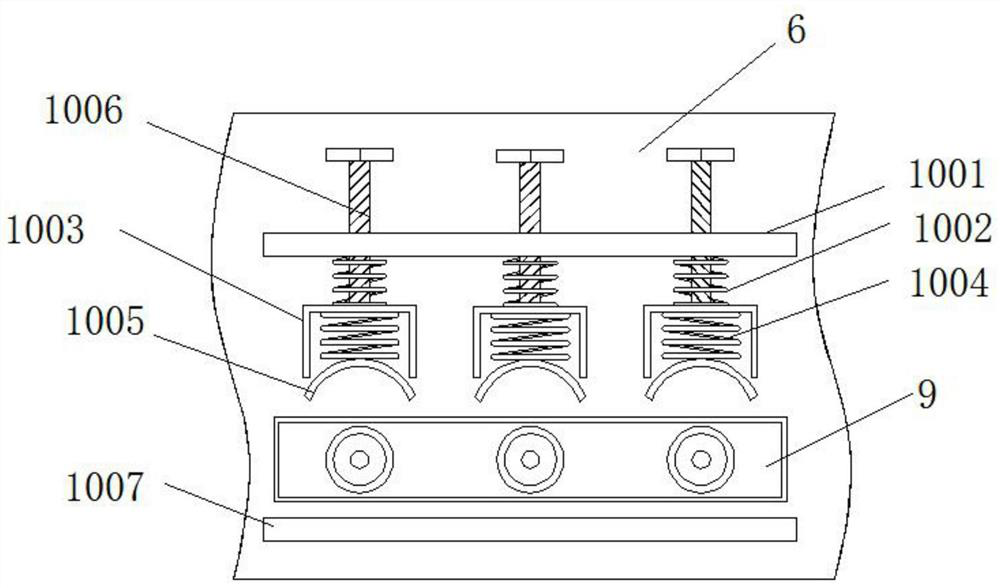

[0042] Example: A 2*300MW unit in a power plant, Shanghai Boiler Factory produces SG-1025-17.6 subcritical, natural circulation boiler, intermediate reheating, four-corner tangential combustion, positive pressure direct blowing pulverization system, and the steam turbine is Dongfang steam turbine The NC300 / 220-16.7-535 / 535 double-cylinder double-exhaust steam extraction and heating unit produced by the factory, the steam turbine is equipped with 4 high-pressure speed-regulating valves and 2 medium-pressure speed-regulating valves, all of which adopt electro-hydraulic Servo valve control, the unit adopts Beijing Hitachi 5000M DCS control system, DEH is integrated in the DCS system, integrated design.

[0043] Symptoms of failure: The operating personnel monitored the panel and found that the opening of the No. 4 high-profile door on the CRT screen was 48%, and it was in the fully closed position on the spot. The thermal engineer forced the door control command to 0, but the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com