Automatic material shoveling control method of loading machine

A control method and loader technology, which are applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., to achieve the effects of high comprehensive operation efficiency, high shovel full rate, and overflow prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

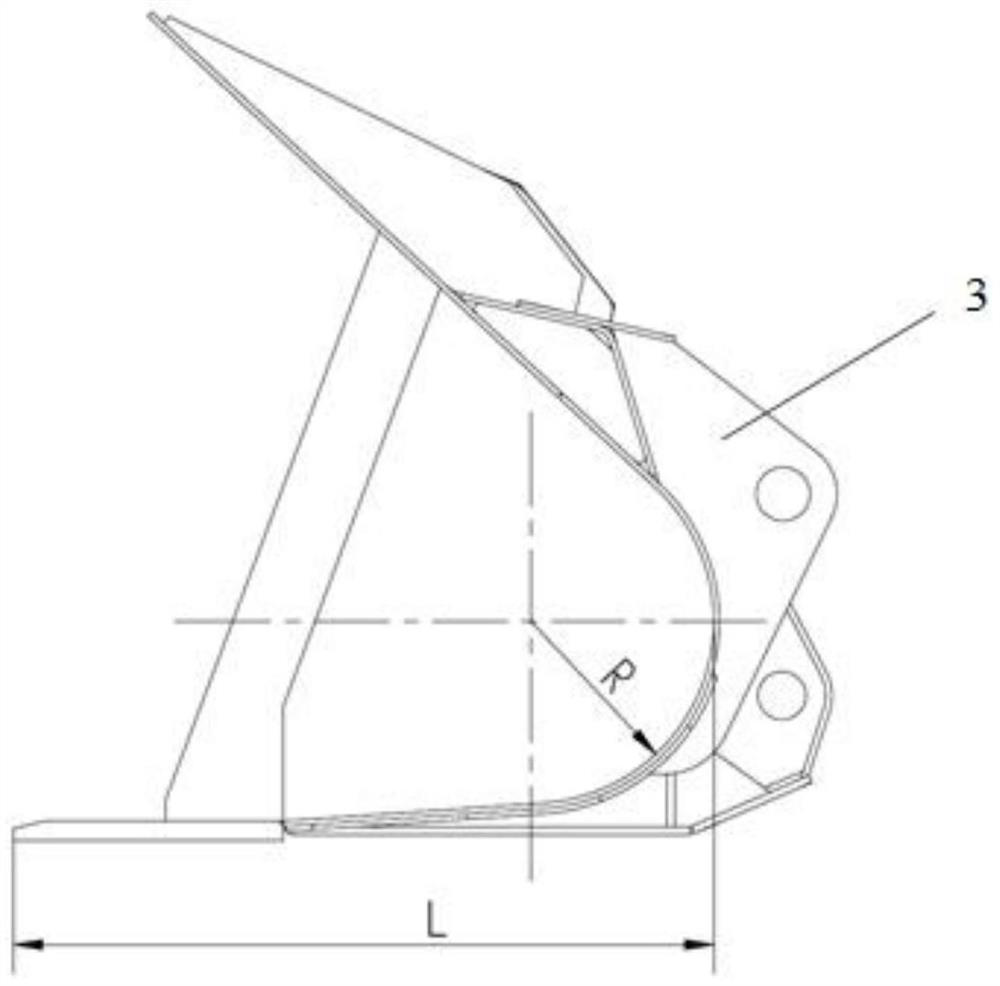

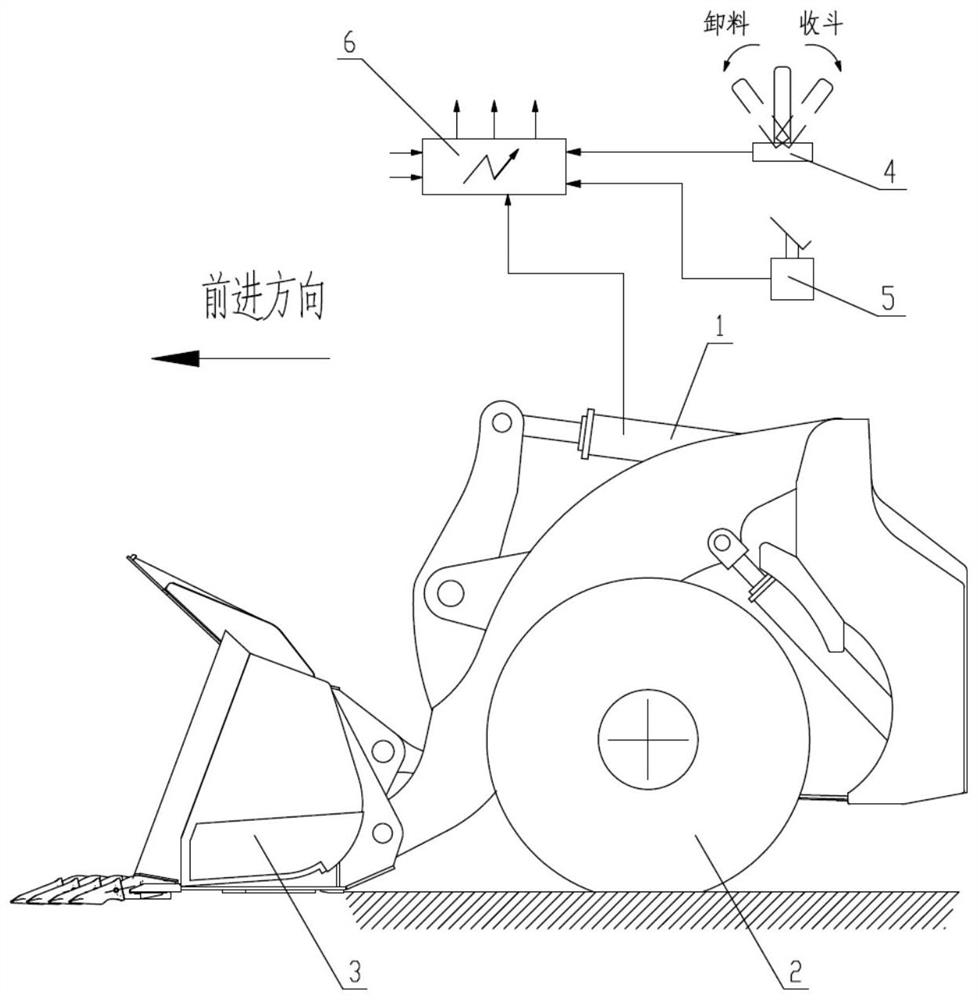

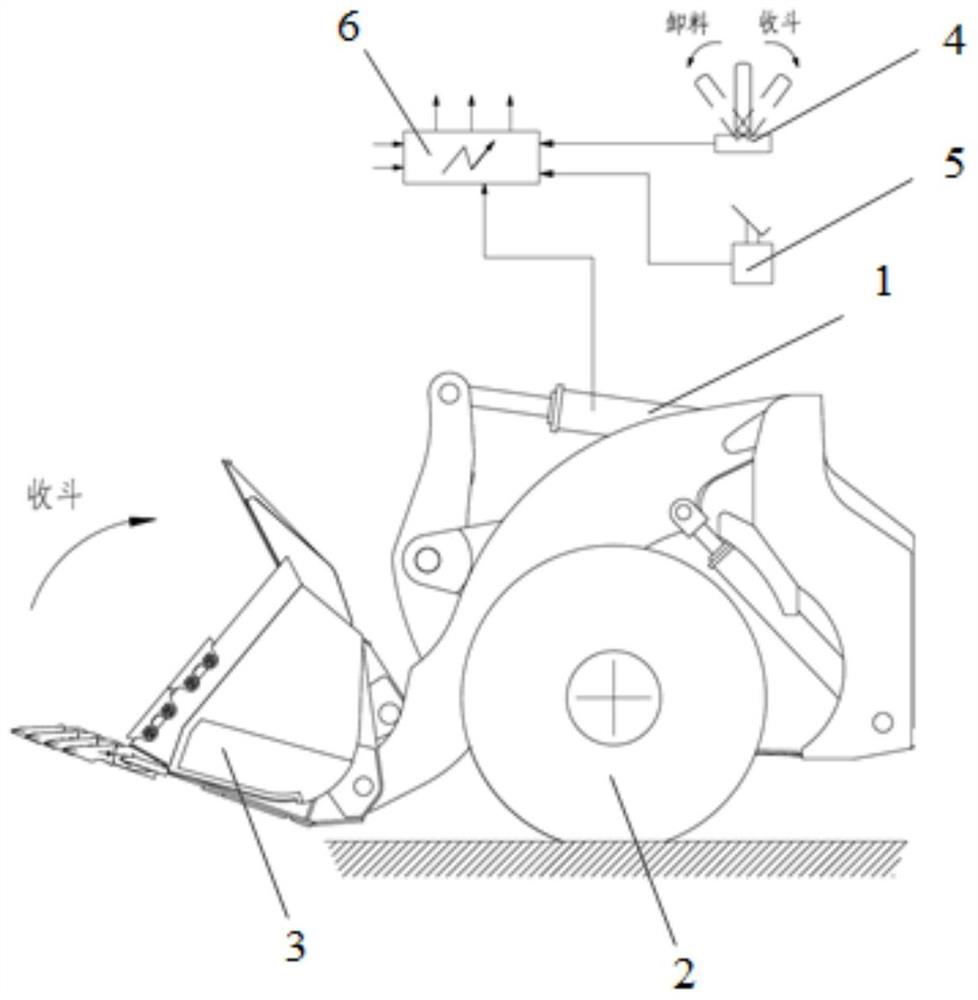

[0030] When the bucket 3 is leveled and enters the stockpile, the controller 6 adjusts the engine to run at a speed corresponding to the maximum torque point. That is to say, the controller 6 can adjust the engine to the working state of the maximum torque point according to the shoveling state of the bucket 3, that is, the speed is the speed corresponding to the maximum torque point, figure 2 It is a schematic diagram of the structure of the bucket 3 on the loader when it is leveled. It can be seen from the figure that the bucket 3 is placed on the ground, the pedal 5 (throttle) can control the walking system 2 through the controller 6, and the handle 4 can be controlled through the controller 6. The bucket 3 is leveled by controlling the bucket cylinder 1 .

[0031]When the sum of the current bucket closing pressure value P1 and the previous bucket closing pressure gradient △ is less than the set pressure P, that is, P1+△

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com