Highly-integrated engine cam bearing cover

A cam bearing, highly integrated technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of VVT system, the normal reset of the VVT rotor, the cleanliness of parts can not be well controlled, and the valve phase can not be very well Good control and other issues, to achieve the effect of simple structure, reduced oil return passage design, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

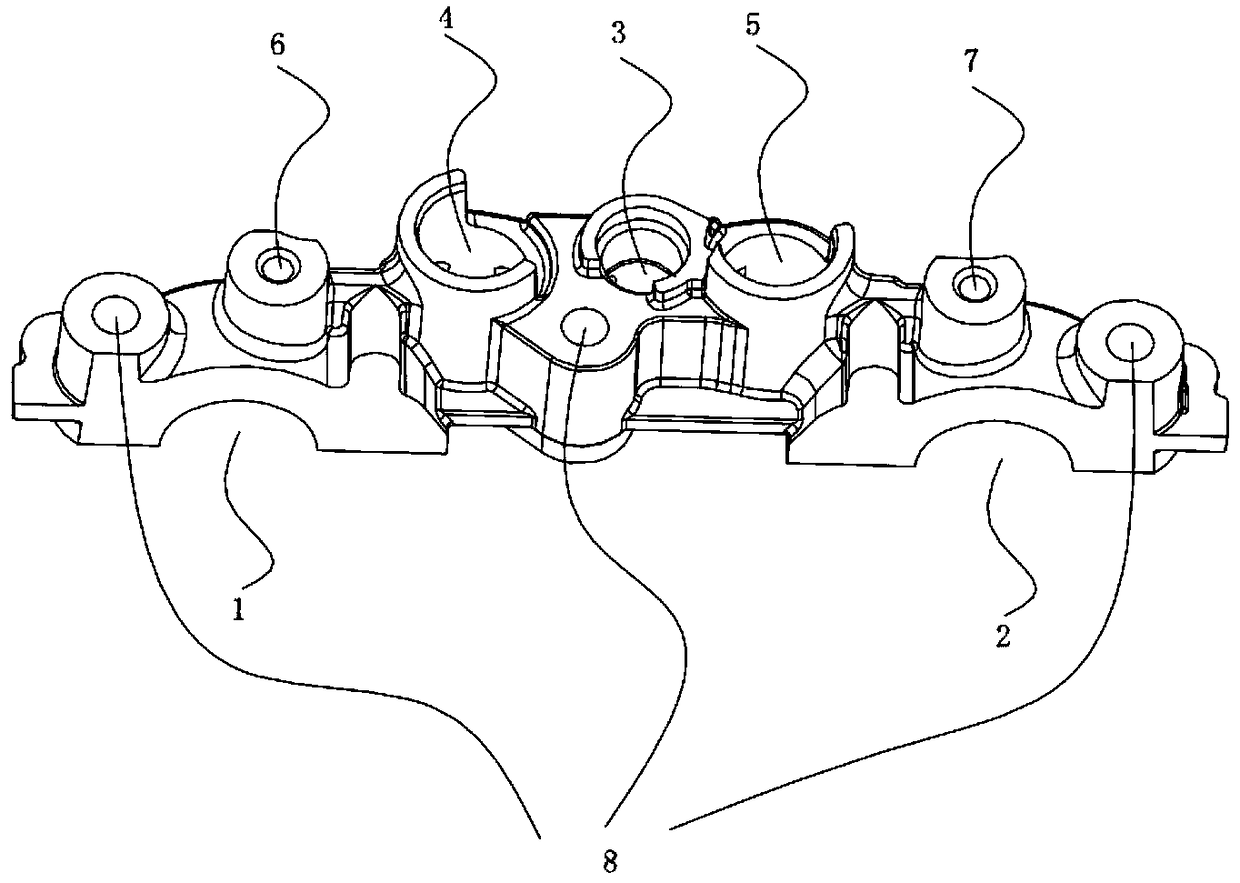

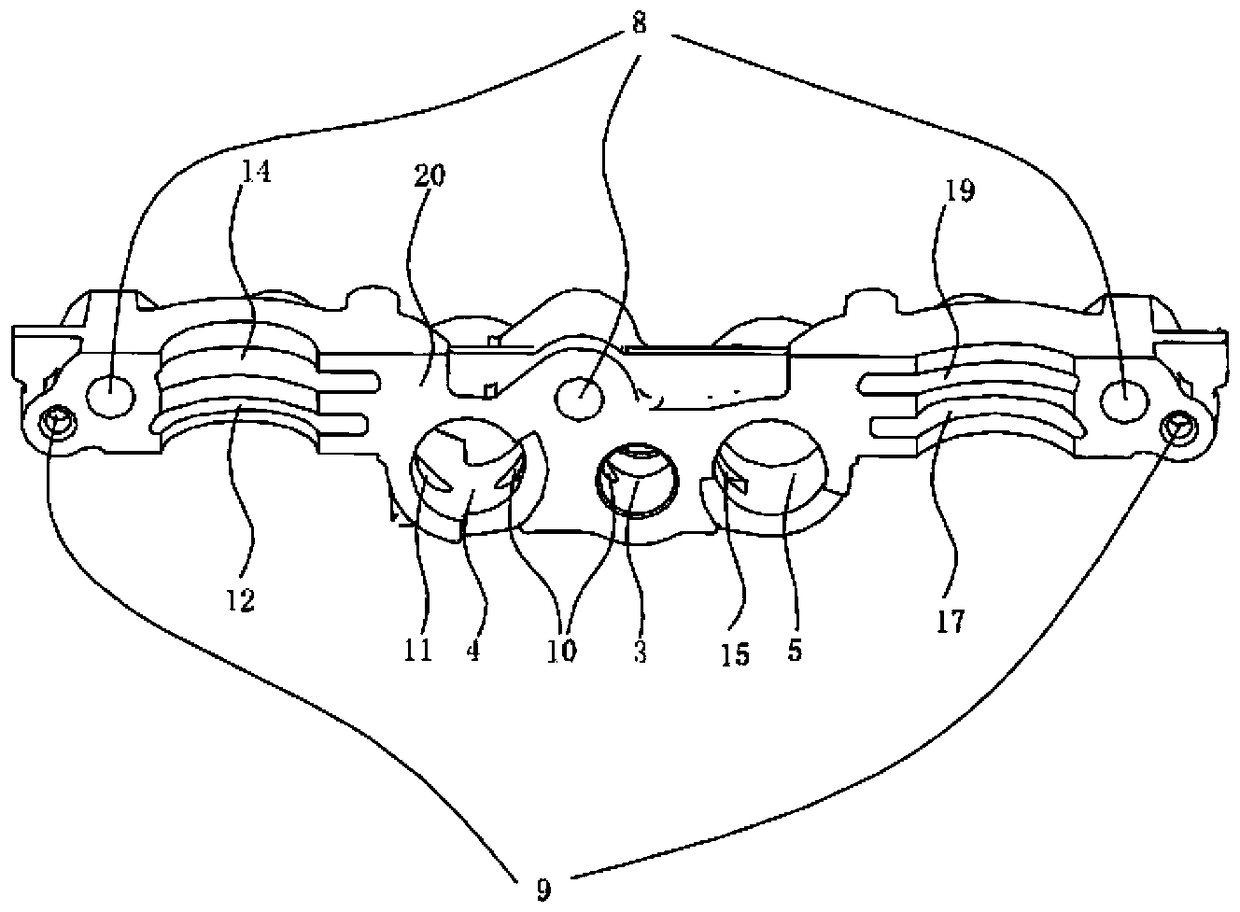

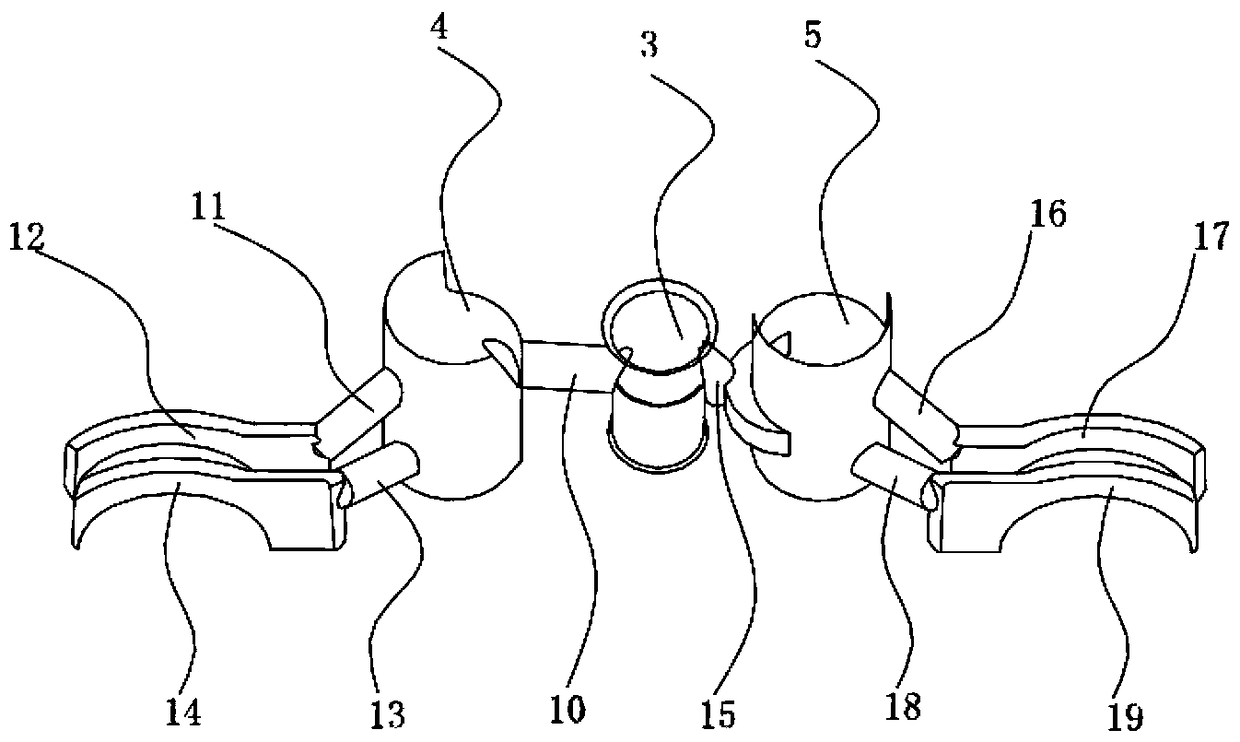

[0013] Such as Figure 1-3 , the highly integrated engine cam bearing cap includes a bearing cap body, which has an exhaust camshaft mounting hole (1), an intake camshaft mounting hole (2) and a surface that fits and seals with the lower cylinder head (20).

[0014] The highly integrated engine cam bearing cover also integrates the VVT main oil channel filter screen and fixing bolt holes (3), intake OCV valve installation holes (4), exhaust OCV valve installation holes ( 5) and VVT oil circuit structure.

[0015] The VVT main oil channel filter screen and fixing bolt holes (3) are arranged in the middle part of the cam bearing cover, and the left and right are respectively the exhaust OCV valve installation hole (4) and the intake OCV valve installation hole (5); There is an exhaust OCV valve P-port oil passage (10) between the channel filter screen and fixing bolt hole (3) and the exhaust OCV valve installation hole (4); between the VVT main oil channel filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com