Rotary positioning and orientation equipment

A positioning, directional, and rotary technology, applied in mechanical equipment, transmission parts, gear transmissions, etc., can solve the problem of excessive axial movement positioning accuracy, and achieve the effect of avoiding parts wear and ensuring coaxiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

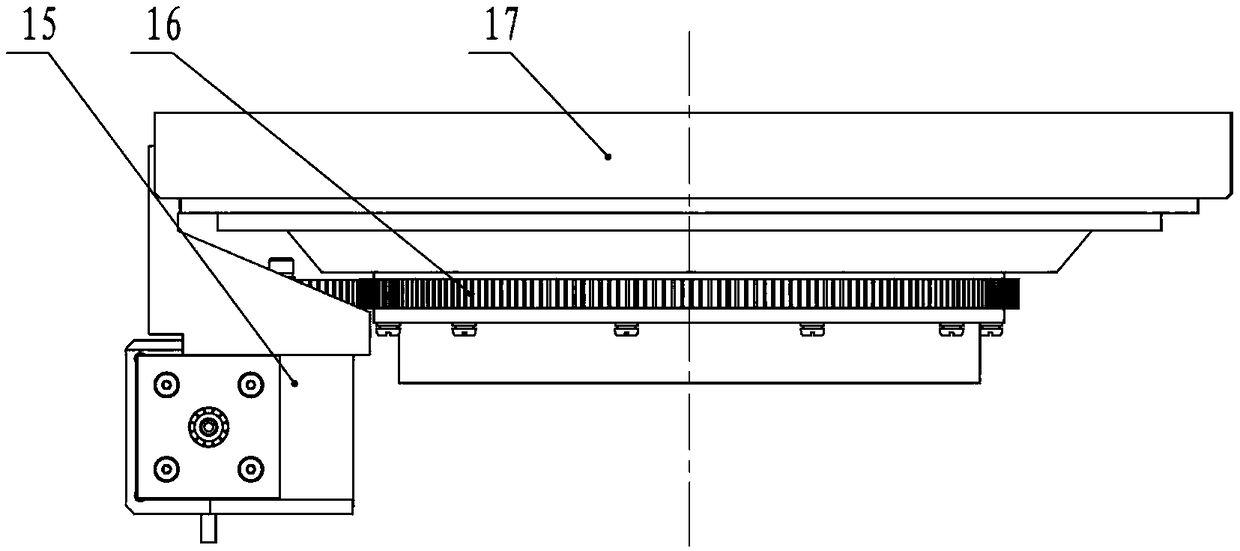

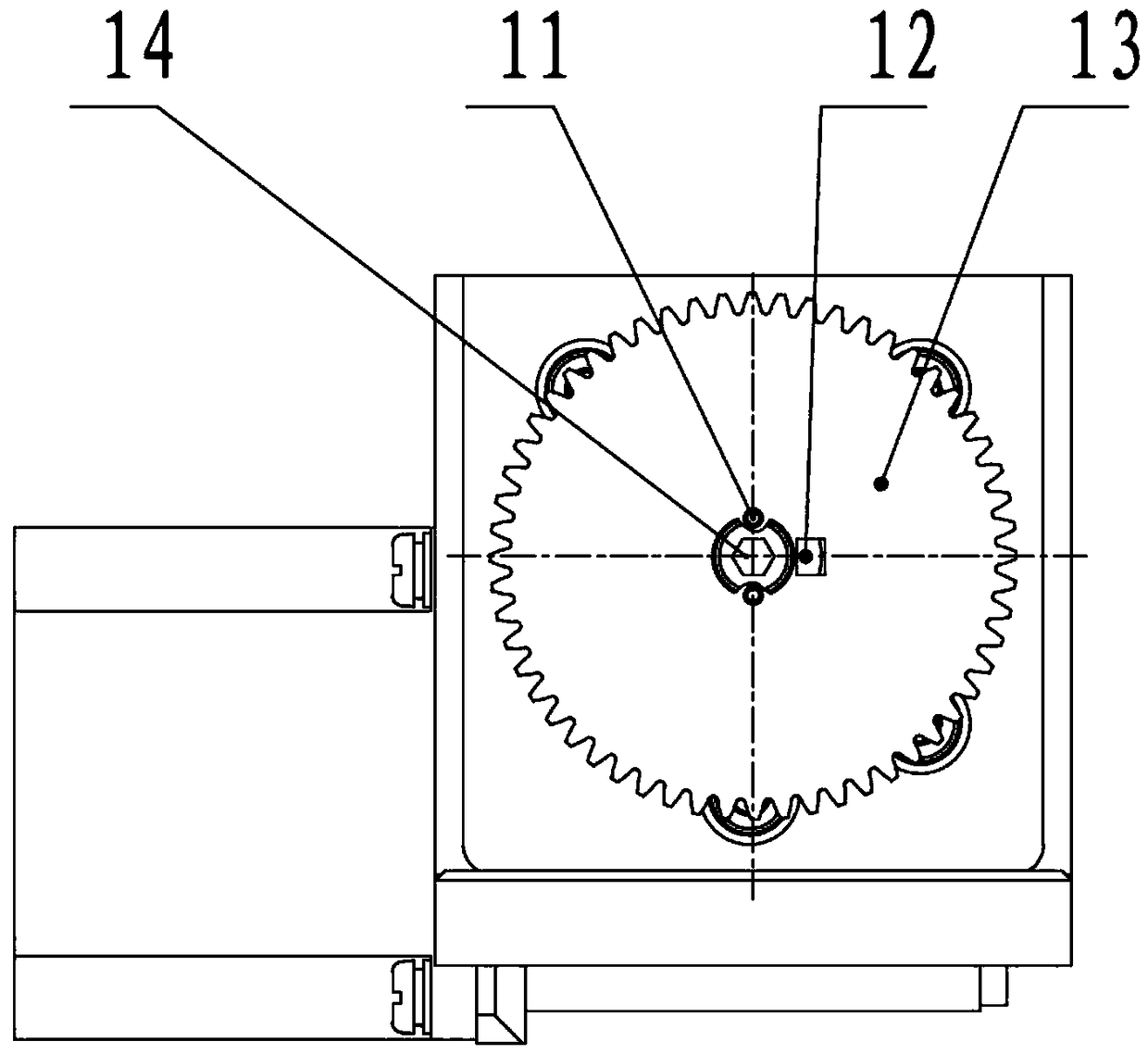

[0014] like figure 1 , figure 2 As shown, a kind of rotary positioning and orientation equipment includes a reducer 15, a rotating mechanism 17, a large gear 16 fixedly connected with the rotating mechanism 17, a pinion 13 driven by the reducer 15 and meshed with the large gear 16, and the reducer 15 is installed on one side of rotating mechanism 17.

[0015] Due to different space design requirements, the present invention proposes a driving scheme of using a worm gear reducer, and the problem of space utilization is effectively solved by installing the reducer on the side. Utilizing the characteristics of large transmission ratio of worm gear transmission, the transmission ratio is increased through two-stage reduction transmission, and a higher driving torque is obtained.

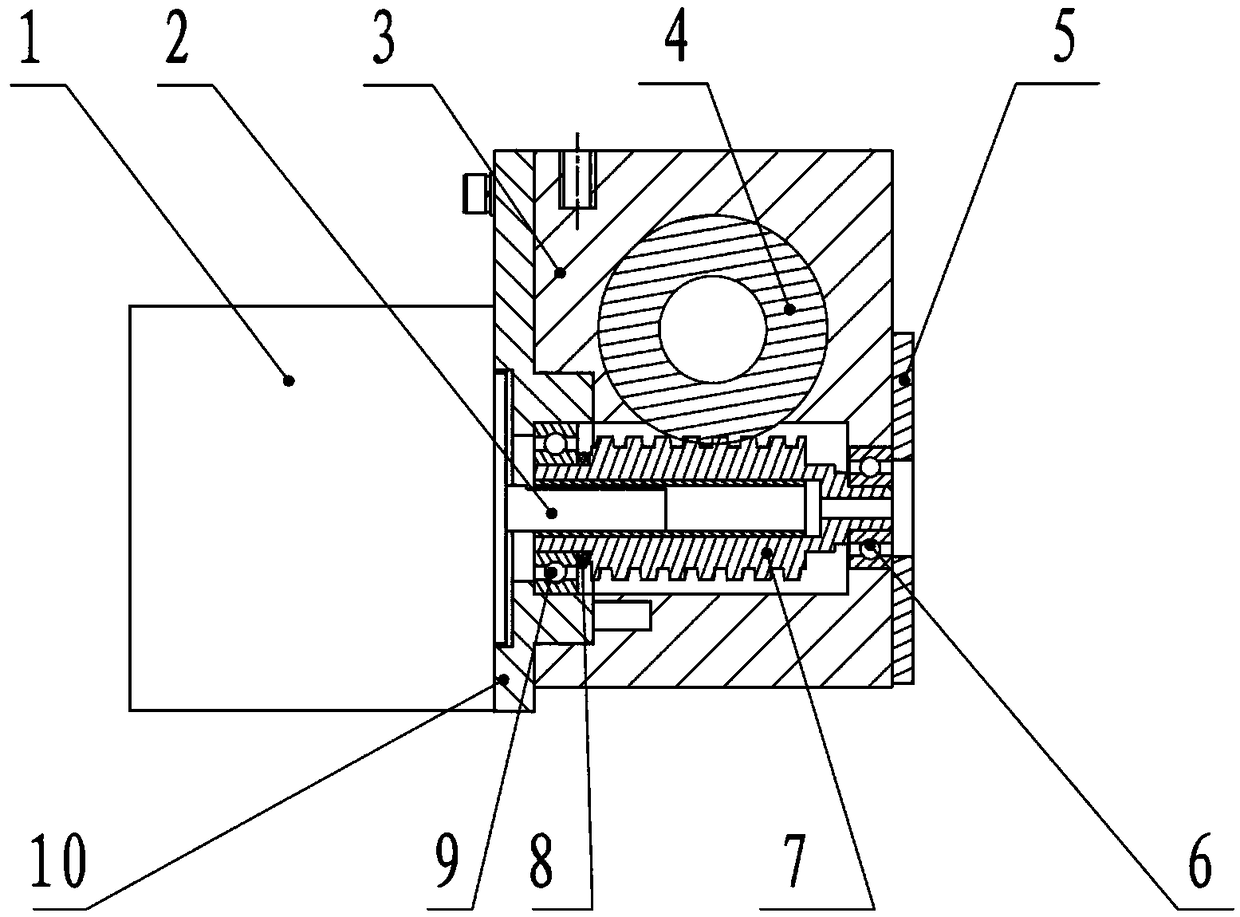

[0016] like image 3 As shown, the reducer includes a stepper motor 1 and a reducer housing 3, the reducer housing 3 is provided with a worm gear 4 and a worm 7 for meshing transmission, the output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com