An experimental device for simulating the iron-condensed layer in the hearth of a blast furnace

An experimental device and blast furnace technology, applied in the field of blast furnace ironmaking, can solve the problems that the temperature and pressure conditions of the blast furnace hearth cannot be simulated, and achieve the effects of low cost, convenient use, and prolonging the life of the blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

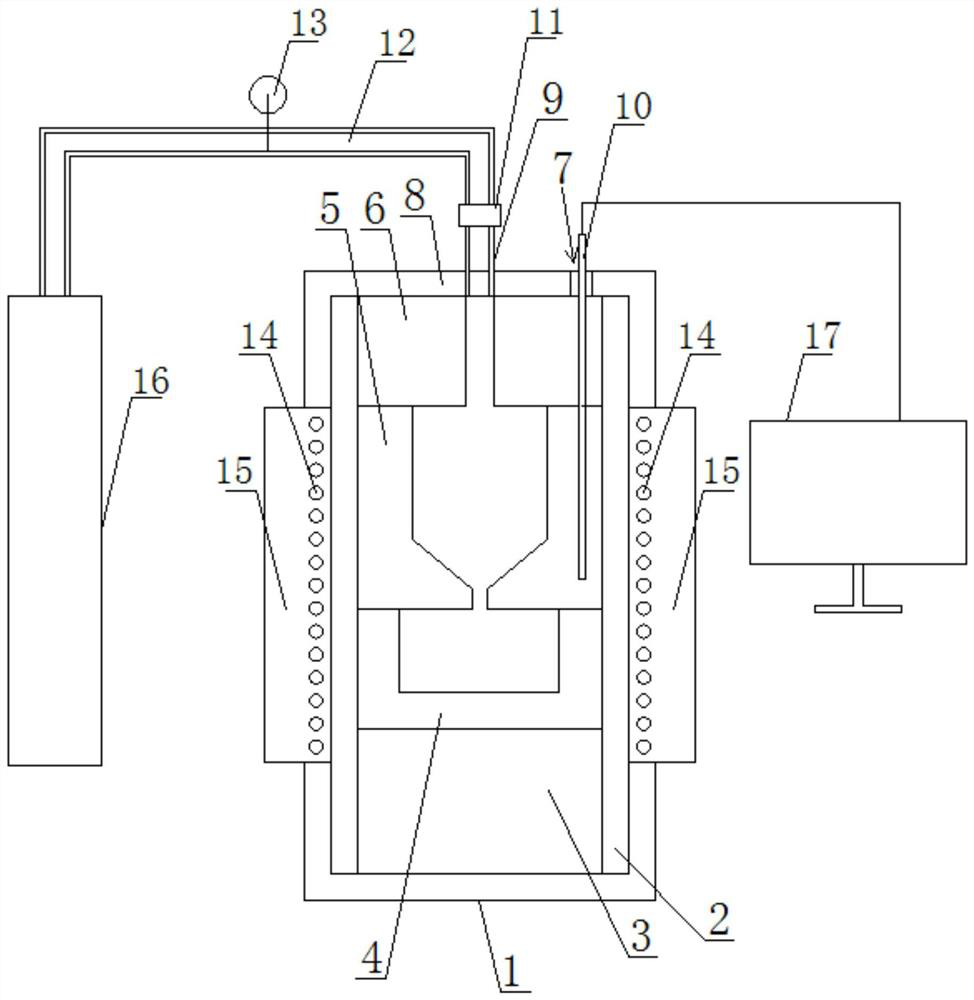

[0038] In a specific embodiment, such as figure 1 As shown, the experimental device for simulating the congealed iron layer in the hearth of a blast furnace includes: a heating sleeve, a thermocouple 10 , a temperature control display device 17 and a gas cylinder 16 .

[0039] The heating sleeve includes a sleeve body 2, a lower cover 1 detachably fixedly connected to the sleeve body 2, and a detachably fixedly connected sleeve body 2. The upper cover 8 is provided with an air inlet and an exhaust port. 7. Specifically, the upper cover 8 is screwed to the sleeve body 2 , and the lower cover 1 is screwed to the sleeve body 2 . The sleeve body 2 is made of steel.

[0040] The upper cover body 8 is provided with an air inlet and an exhaust port 7, and a bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap