A defect detection method for PCB

A defect detection, PCB board technology, applied in image data processing, instrument, character and pattern recognition, etc., can solve problems such as low gray value and missed detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0065] For the defect detection method of PCB, the steps are as follows:

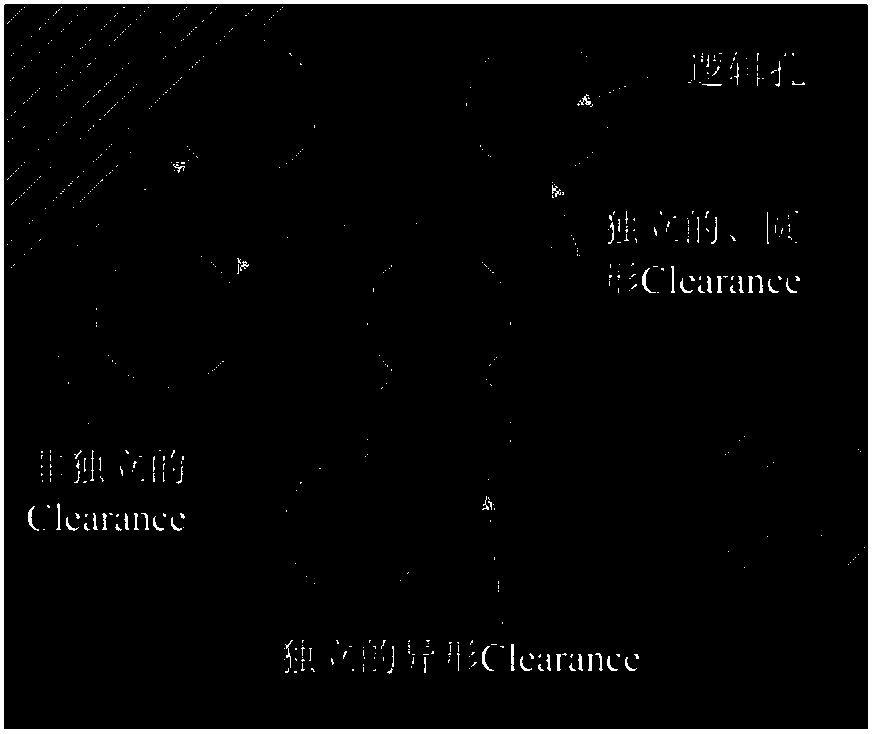

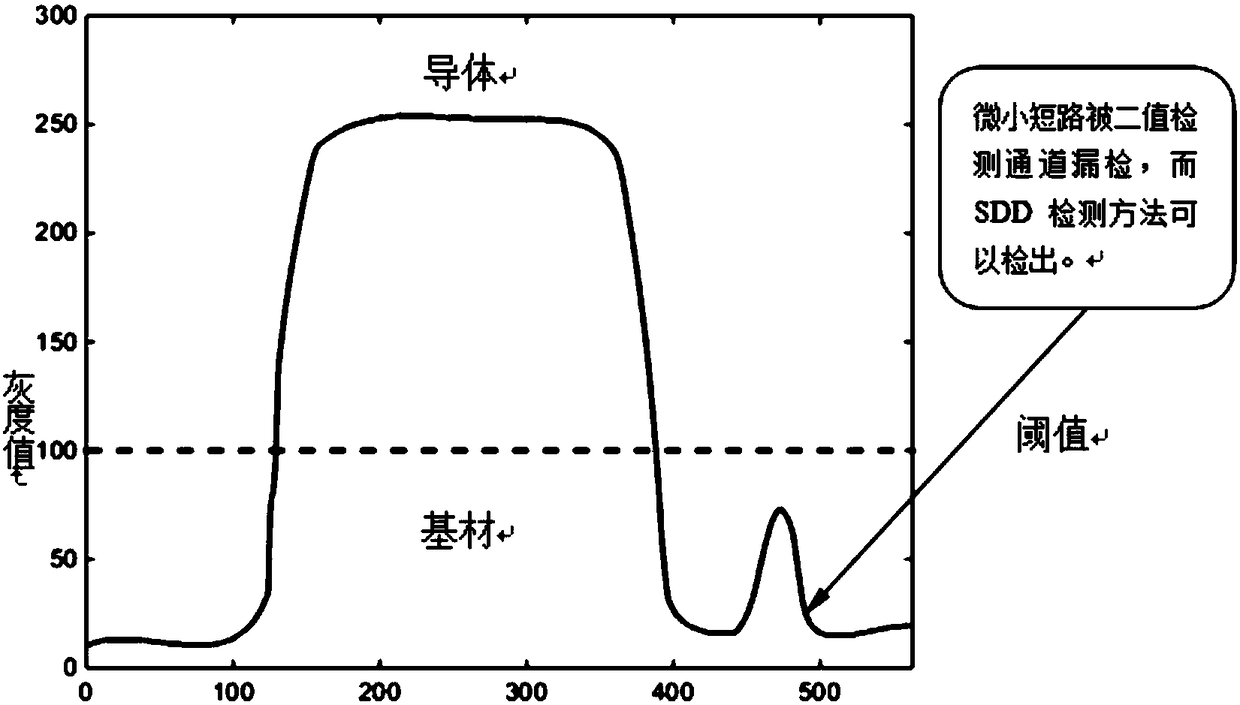

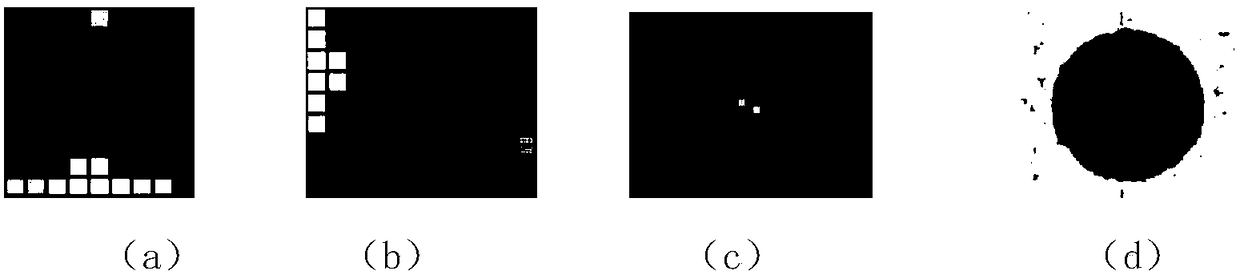

[0066] The tiny defects of the PCB board are divided into micro short circuits, micro burrs and isolated defects according to the number of connected conductors, such as image 3 , wherein the tiny short circuit means a tiny defect connecting two conductors, the tiny burr means a tiny defect connecting a conductor, and the isolated defect means a tiny defect not connecting a conductor. For the first two types, the tiny short circuit and tiny burr will affect the electrical conductivity of the PCB board, so it needs to be detected, and for the isolated defect that is not connected to the conductor, it needs to be judged whether it is a blank area inside the clearance, if it is located In the blank area, the isolated defects located in the blank area need to be detected, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com