Method for reducing water and soil loss of sloping tobacco field

A technology for sloping fields and tobacco fields, applied in the field of reducing soil erosion in sloping tobacco fields, can solve the problems of limited tobacco fields on sloping fields, and achieve the effects of slowing down water loss, increasing organic matter, and reducing ground temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

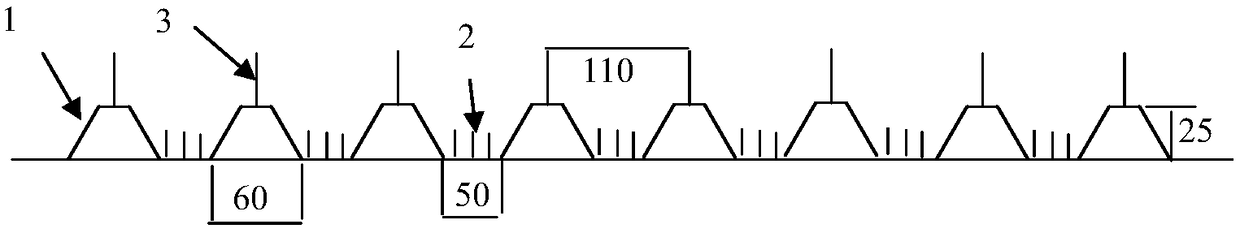

[0024] Such as figure 1 As shown, the method for reducing soil erosion in slope tobacco field of the present embodiment comprises the following steps:

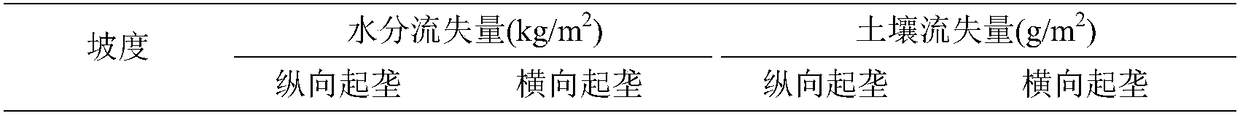

[0025] 1) Before ridging, apply chemical fertilizers horizontally along the extension direction of the contour line of the slope to form a strip-shaped fertilizer belt. The amount of fertilizer applied is selected according to the nutrient status and conventional consumption of the local tobacco soil; the slope of the slope of the present embodiment is 7.3°;

[0026] 2) Use a small ridge filming machine to form ridges along the extension direction of the contour line of the slope, and cover the ridges with plastic film 1 to ensure that the fertilizer applied is just below the ridges; the distance between two adjacent ridges is 110cm, the spacing refers to the distance between the centerline of the top of one ridge and the centerline of another adjacent ridge; the height of the ridge is 25cm, the width of the bottom of the rid...

Embodiment 2

[0032] The gradient of the slope of the present embodiment is 10°, and others are all the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com