Automatic embedding fixture for cylinder sleeves of universal double-cylinder body die-casting mold

A die-casting mold and fixture technology, applied in the field of mechanical processing and manufacturing, can solve the problems of unrealized automation and low degree of automation, and achieve the effect of improving automatic production capacity and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

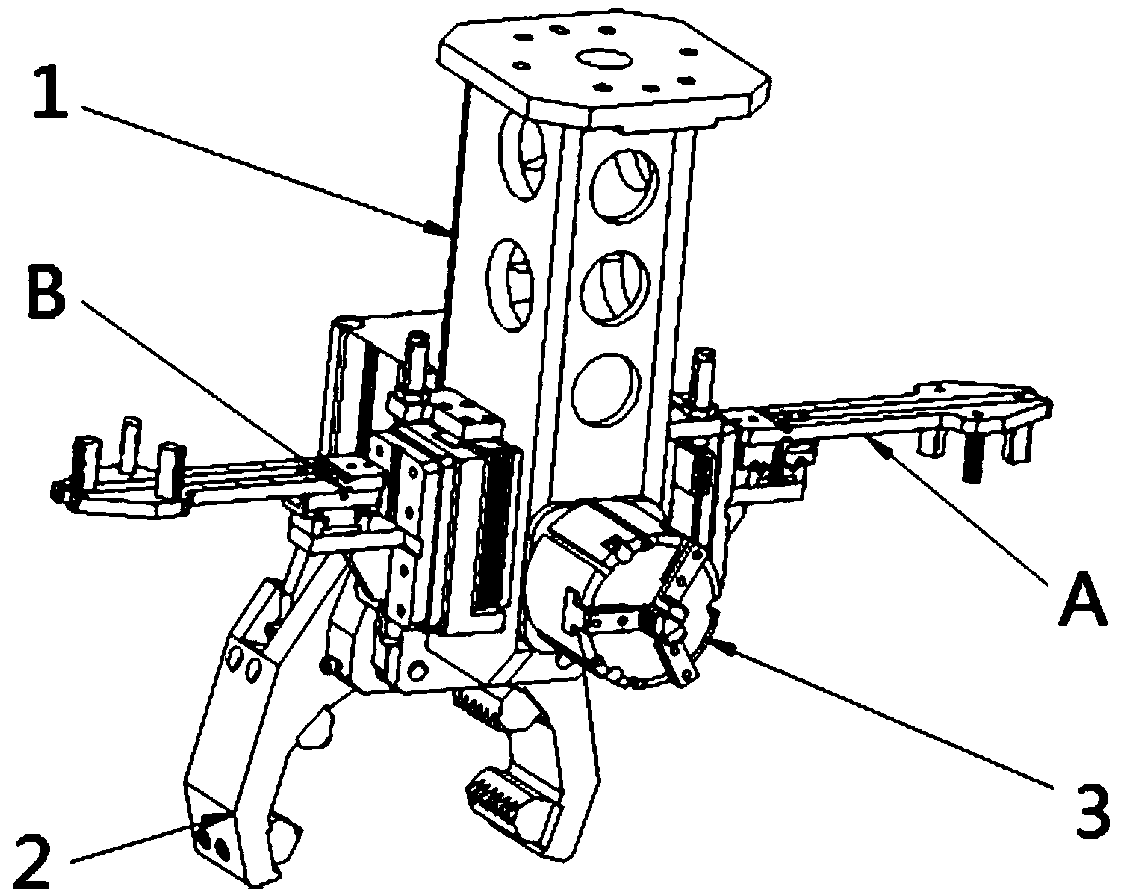

[0014] Such as figure 1 As shown in the figure, a general-purpose double-cylinder die-casting mold cylinder liner automatic mosaic fixture is mainly composed of fixture body 1, material handle fixture 2, product fixture 3, cylinder liner fixture A of the first station and cylinder liner fixture B of the second station composition. The material handle clamp 2 and the product clamp 3 are arranged on the clamp main body 1, and the clamp main body 1, the material handle clamp 2 and the product clamp 3 belong to the existing structures, and will not be repeated here.

[0015] The difference is that: the cylinder liner clamp A of the first station and the cylinder liner fixture B of the second station are arranged on the left and right sides of the fixture main body 1 respectively.

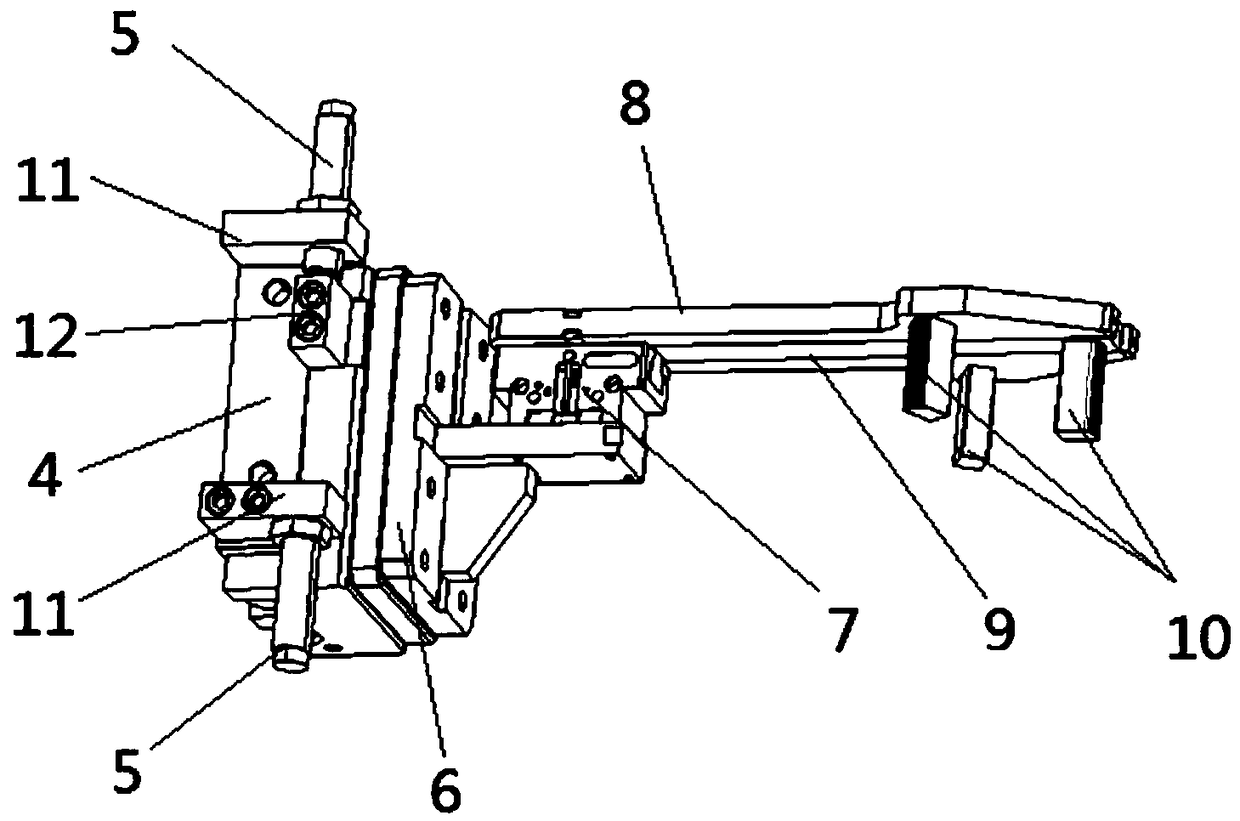

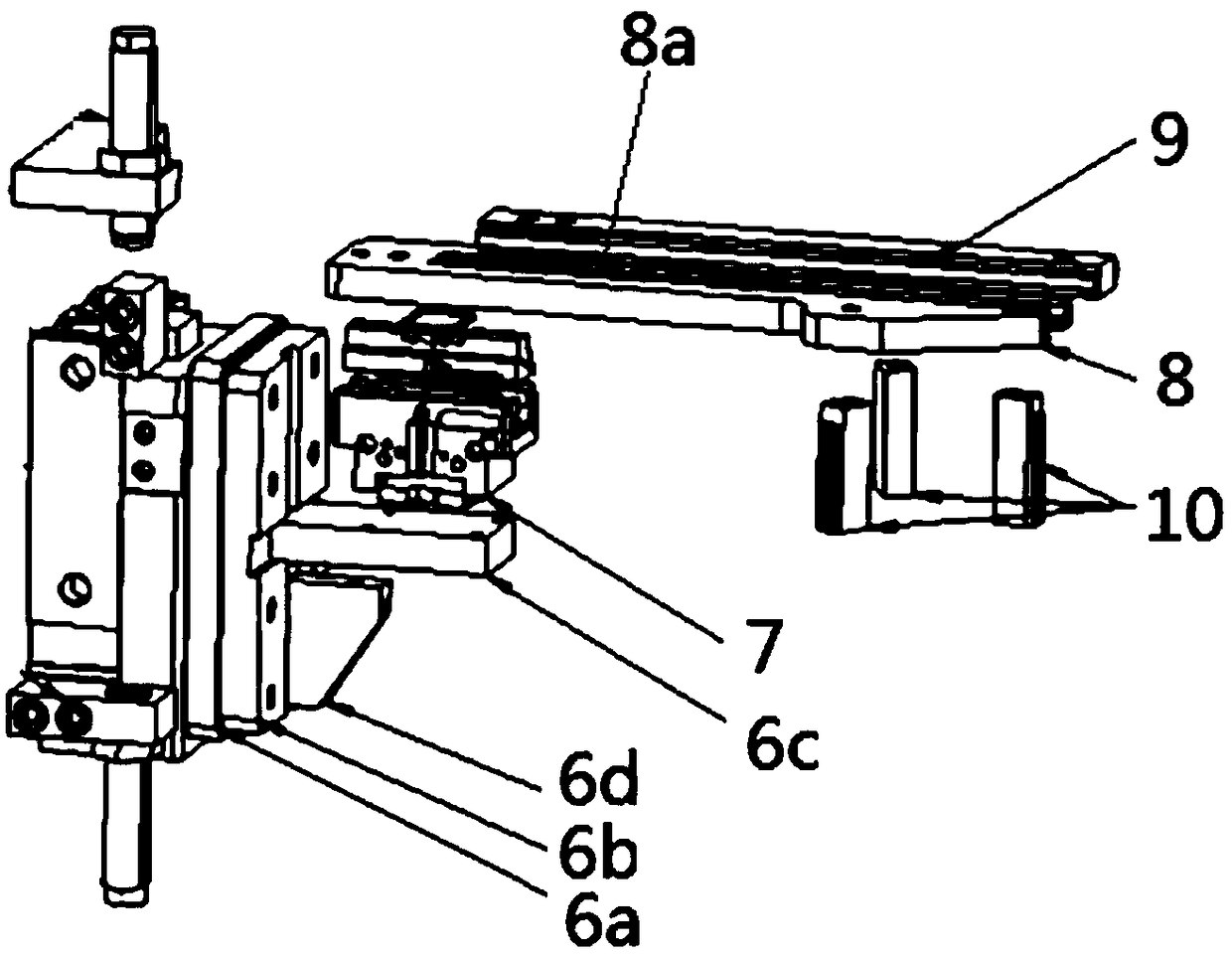

[0016] combine figure 1 — image 3 As shown, the structure of the No. 1 cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com