Shifting fork mechanism for driving fluid sliding ring

A technology for driving fluids and slip rings, applied in ship parts, ships, anchoring arrangements, etc., can solve the problems of eccentric wear, abnormal noise and vibration of fluid slip rings, and achieve the effect of reducing wear and prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

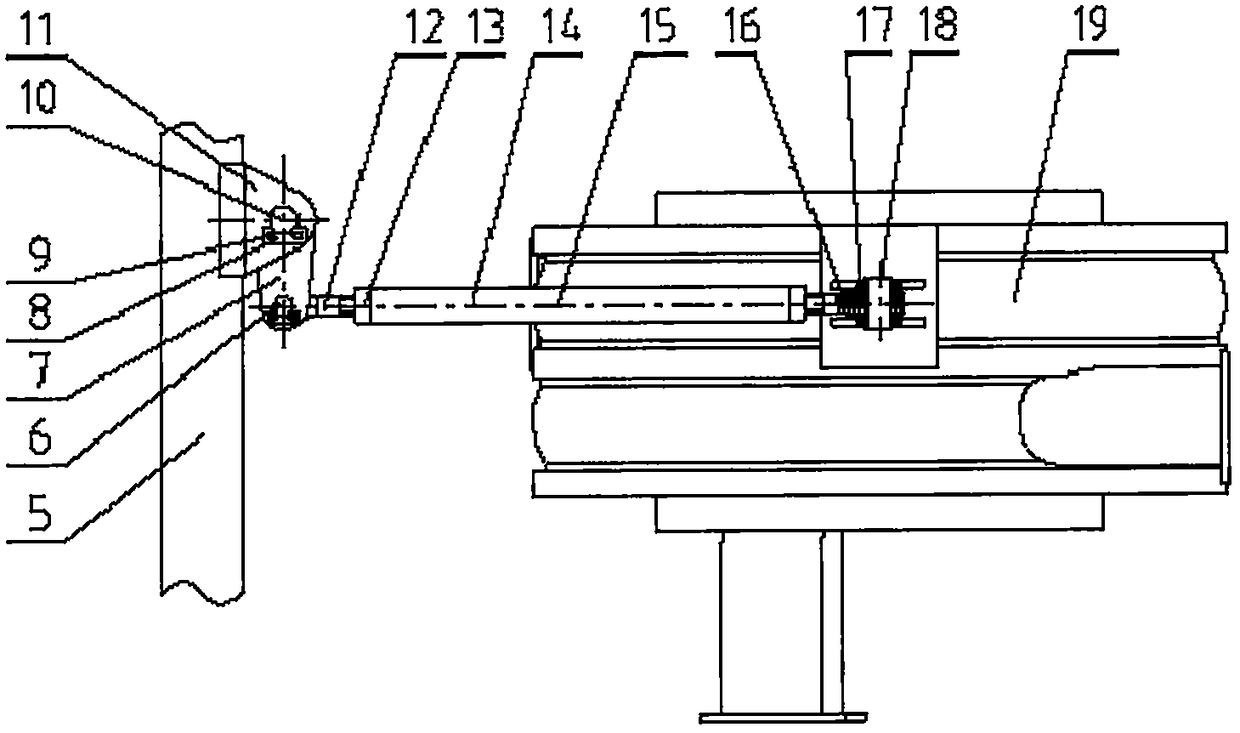

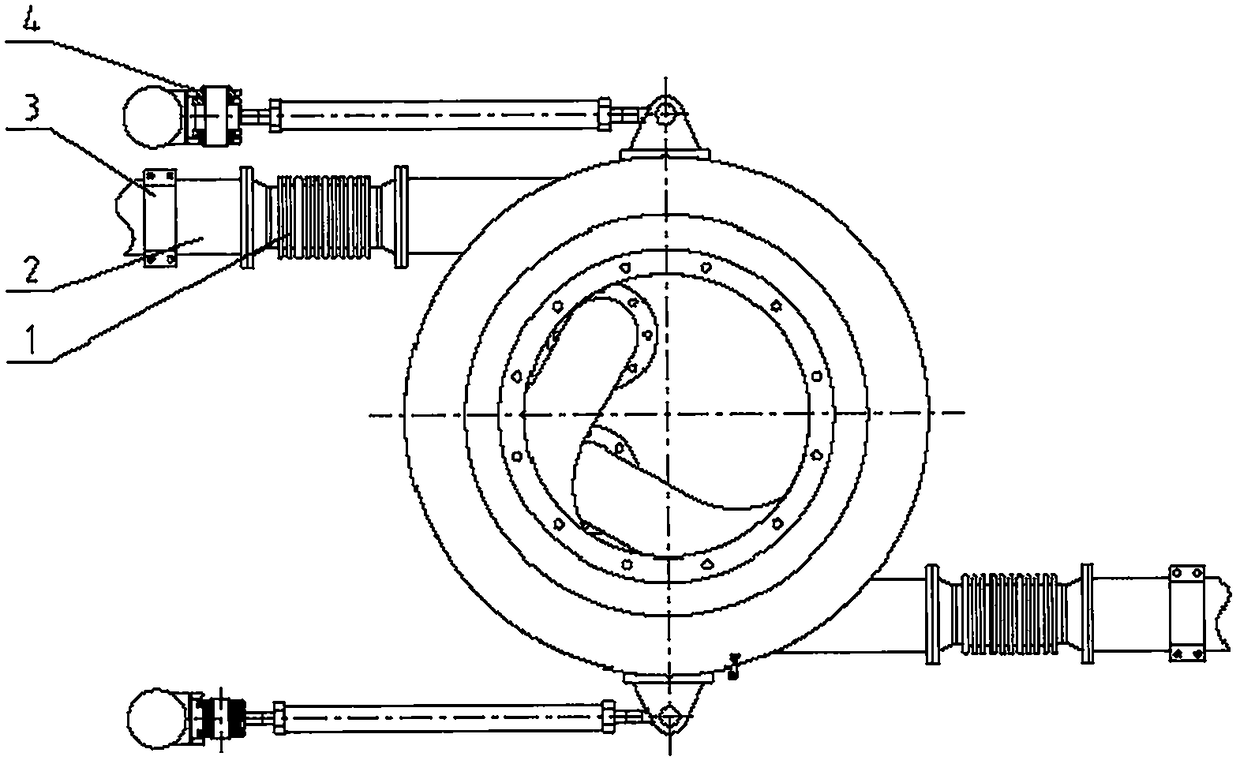

[0022] refer to figure 1 , figure 2 As shown, they are respectively the front view and top view of the fork mechanism for driving the fluid slip ring provided by the embodiment of the present invention. The fork mechanism for driving the fluid slip ring includes a fluid slip ring soft connection device and two symmetrically arranged forks. The fluid slip ring soft connection device includes a bellows 1, an external connecting pipe 2 and a fluid slip ring 19. One end of the bellows 1 is connected to the flow port of the outer ring of the fluid slip ring 19 through a flange, and the other end is connected to the outside through a flange. The pipes 2 are connected, and the outer connecting pipe 2 is fixed on the rotating tower through a fixed support 3 .

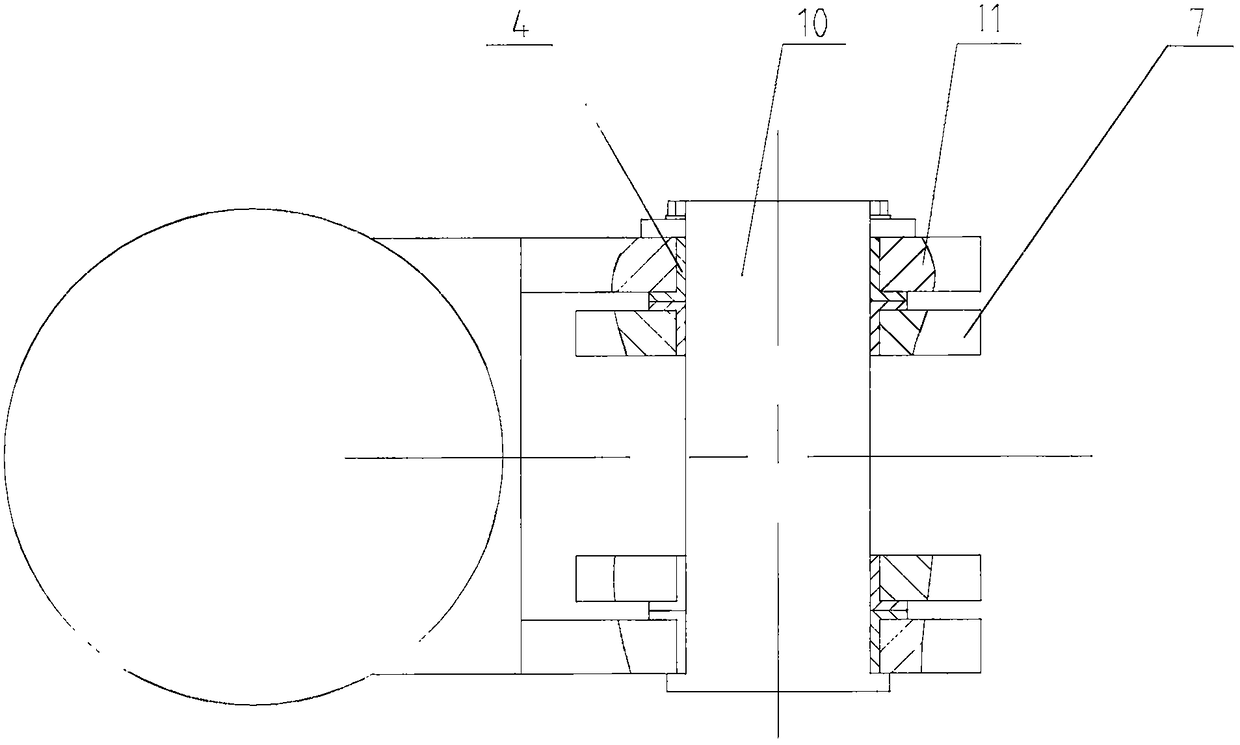

[0023] The shift fork includes a column 5, a fixed lug 11, a small connecting rod 7, and a large connecting rod 15. The column 5 is a part of the rotating tower structure. One end of the fixed lug 11 is welded on the column 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com