Guide rope equipment for ships and installation method thereof

A technology for ships and fairleads, applied in the direction of ships, etc., can solve the problems of worn cables and decks, personnel injuries, inconvenient replacement, etc., and achieve the effect of increasing strength, not easy to wear, and easy to disassemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

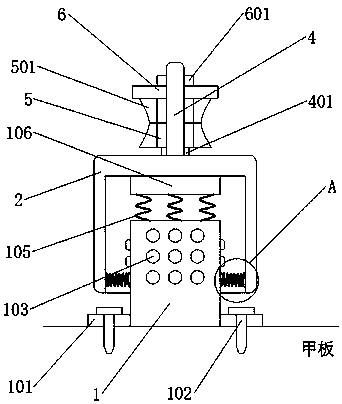

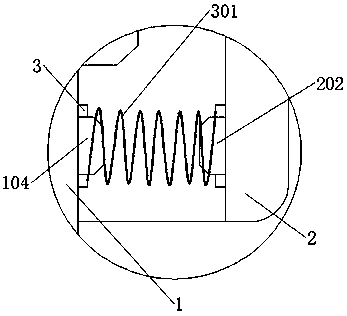

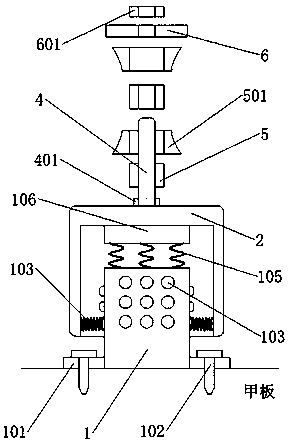

[0048] see Figure 1-5 , a ship guide cable device, comprising a main fixed base 1, an auxiliary fixed ring 101 is fixedly connected to the lower end of the main fixed base 1, a plurality of threaded holes are drilled on the auxiliary fixed ring 101, and fastening screws are threaded on the threaded holes 102, the main fixed base 1 is dug with a plurality of first limit through holes 103, the main fixed base 1 is sleeved with a roller fixed frame 2, and the roller fixed frame 2 is dug with a plurality of first limit through holes 103 are all matching second limiting through holes 201, the number of first limiting through holes 103 and second limiting through holes 201 is at least nine, and there are at least three first limiting through holes 103 and second limiting through holes The position through hole 201 runs through the center of the main fixed base 1, which can control the roller fixed frame 2 to rotate in a small range within the normal range, and a limit shaft column ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com