Anti-static floor and manufacture process thereof

An anti-static floor and preparation process technology, which is applied to buildings, building structures, floors, etc., can solve problems such as poor hardness, poor wear resistance, and cannot meet actual use needs, and achieves a simple preparation process and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

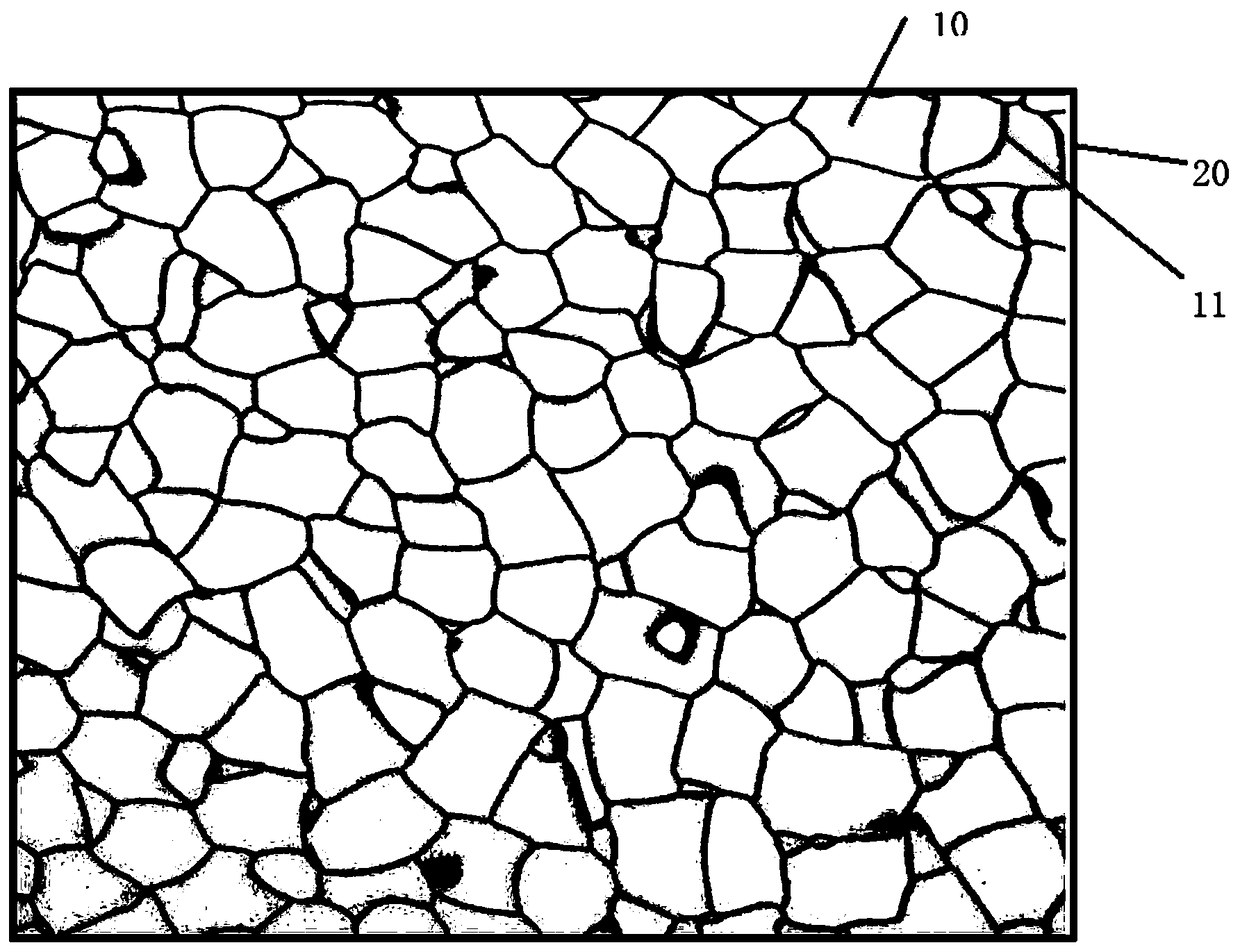

[0031] An anti-static floor, including a square anti-static floor in the middle, and edge elastic strips located on the four sides of the anti-static floor. The anti-static floor in the middle can lead out current, and the anti-static floor in the middle is generally 60*60cm. Its thickness is 3mm, and the edge elastic strips are set on the four sides of the anti-static floor. .

[0032] The production method of anti-static floor is as follows:

[0033] S1. Preparation of reference particles: mix PVC, calcium carbonate, stabilizer, plasticizer, and lubricant, heat up to 160°C for hot-melt stirring, and send out cylindrical particles through an extruder;

[0034] S2. Preparation of conductive base material: Grinding the carbon fiber into powder for later use;

[0035] S3. Surface treatment of reference particles: put the particles prepared in step S1 into solid hot melt adhesive in a hot-melt state at 150°C, stick a layer of hot-melted solid hot melt adhesive on the surface of...

Embodiment 2

[0043] An anti-static floor, including a square anti-static floor in the middle, and edge elastic strips located on the four sides of the anti-static floor. The anti-static floor in the middle can lead out current, and the anti-static floor in the middle is generally 80*80cm. Its thickness is 4mm, and the edge elastic strips are arranged on the four sides of the anti-static floor. error.

[0044] The production method of anti-static floor is as follows:

[0045] S1. Preparation of reference particles: mix PVC, calcium carbonate, stabilizer, plasticizer, and lubricant, heat up to 160°C-180°C for hot-melt stirring, and send out cylindrical particles through an extruder;

[0046] S2. Preparation of conductive base material: Grinding the carbon fiber into powder for later use;

[0047] S3. Surface treatment of reference particles: put the particles prepared in step S1 into the solid hot melt adhesive in a hot melt state at 155°C, stick a layer of hot melted solid hot melt adhesi...

Embodiment 3

[0055] An anti-static floor, including a square anti-static floor in the middle, and edge elastic strips located on the four sides of the anti-static floor. The anti-static floor in the middle can lead out current, and the anti-static floor in the middle is generally 80*80cm. Its thickness is 5mm, and the edge elastic strips are arranged on the four sides of the anti-static floor. .

[0056] The production method of anti-static floor is as follows:

[0057] S1. Preparation of reference particles: mix PVC, calcium carbonate, stabilizer, plasticizer, and lubricant, heat up to 160°C-180°C for hot-melt stirring, and send out cylindrical particles through an extruder;

[0058] S2. Preparation of conductive base material: Grinding the carbon fiber into powder for later use;

[0059] S3. Surface treatment of reference particles: put the particles prepared in step S1 into the solid hot melt adhesive in a hot melt state at 160°C, stick a layer of hot melt solid hot melt adhesive on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com