Nano-copper-based two-dimensional sheet-like cerium oxide nanomaterial and its synthesis method and application

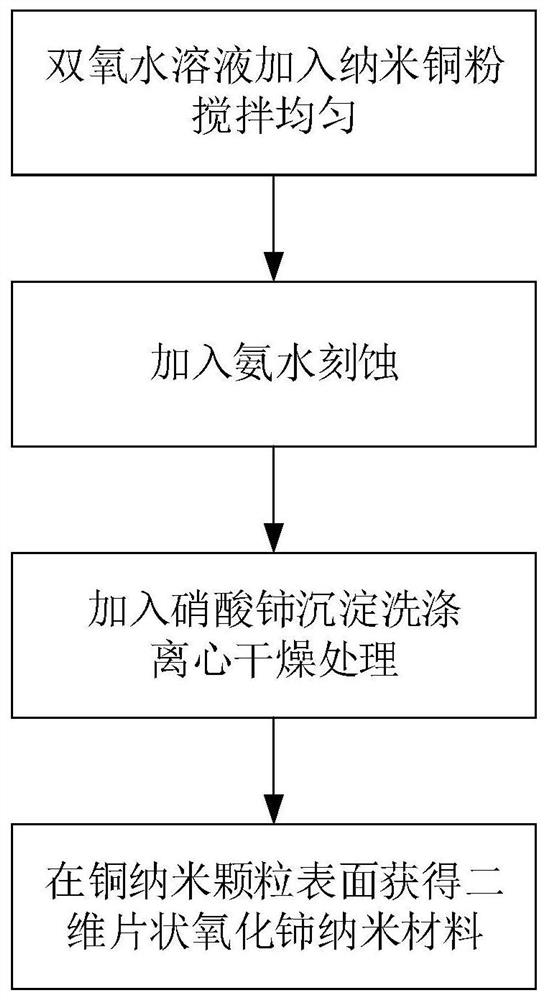

A technology of nanomaterials and synthesis methods, which is applied in the field of preparation of two-dimensional flake cerium oxide nanomaterials, can solve the problems of long preparation period, difficult removal of surfactants, secondary pollution, etc., and achieves good surface wrapping quality, simplicity and convenience. manipulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

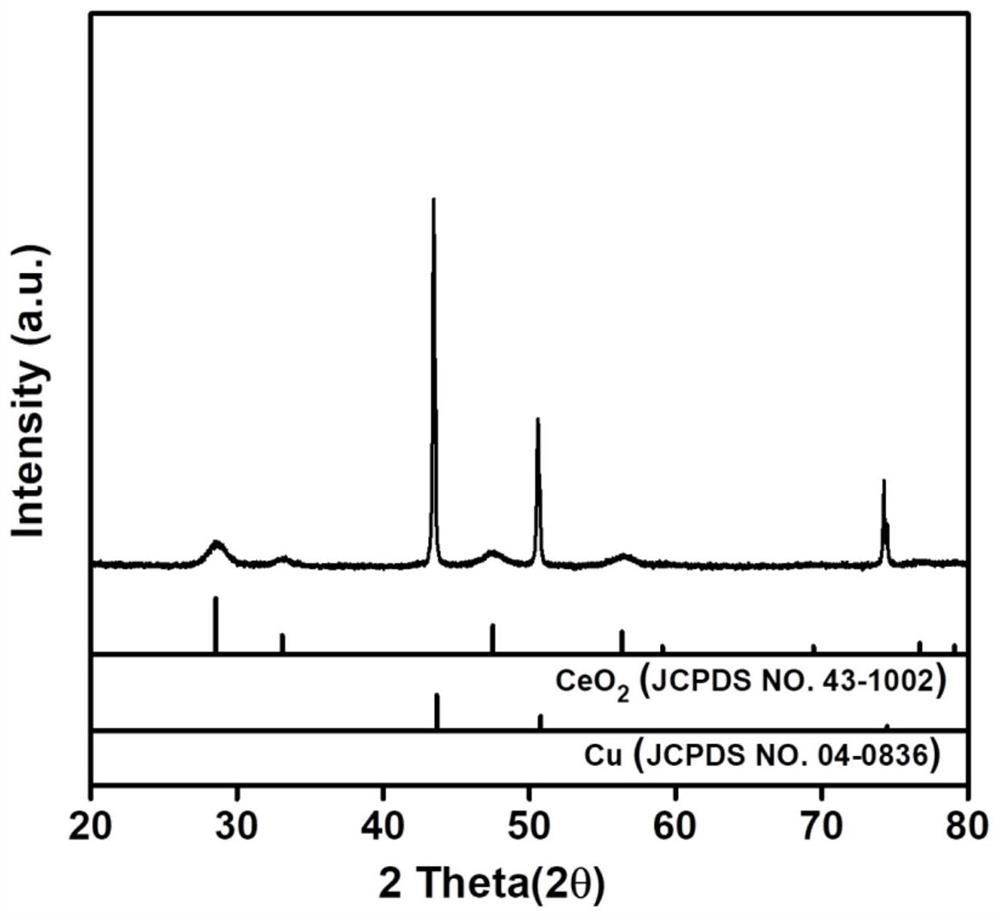

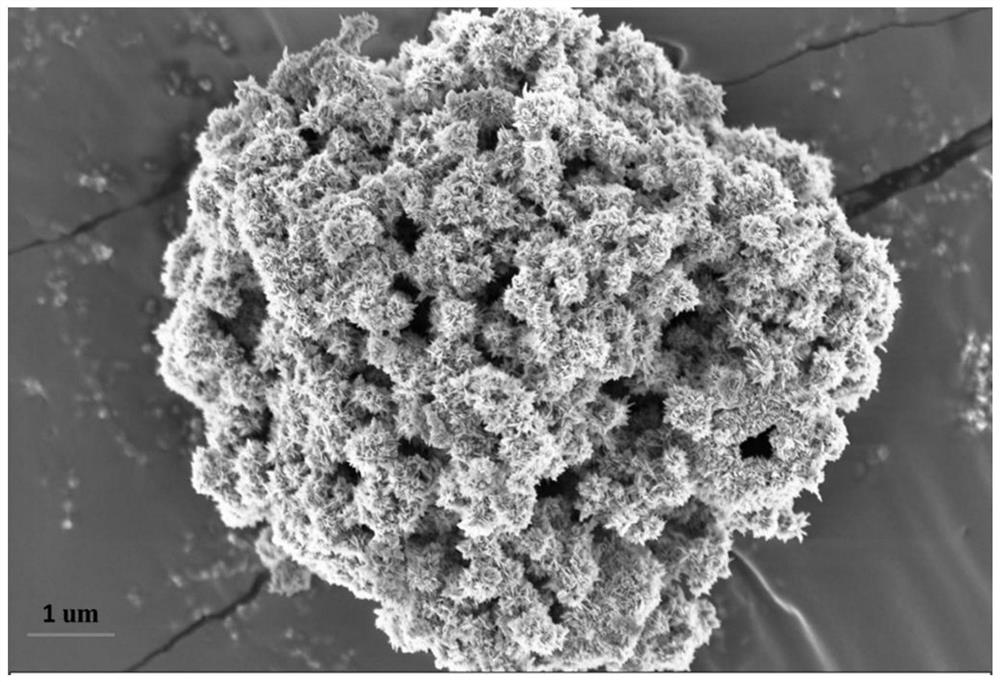

[0055] Disperse 0.3g of nano-copper powder in 4ml of 15% hydrogen peroxide, soak for 10min, add 10ml of 10% ammonia water, and stir in the beaker at a speed of 400rpm for 2h. Due to the reaction between the oxide layer and ammonia water, the mixed solution will appear pale. Blue, drop 2ml of cerium nitrate with a mass fraction of 30% into the mixed solution to obtain a gray precipitate, stir at 400rpm and age for 20min, collect the precipitate sample and wash it with deionized water, then centrifuge at 6000rpm, repeat washing and centrifugation 5 times, Dry in an oven at 80°C for 24h to obtain nano-copper-based two-dimensional sheet-like cerium oxide nanomaterials.

Embodiment 2

[0057] Disperse 0.2g of nano-copper powder in 4ml of 15% hydrogen peroxide, soak for 10min, add 10ml of 10% ammonia water, stir in the beaker at 400rpm for 1h, the mixed solution appears light blue, add 2ml of the mixed solution dropwise The mass fraction was 30% cerium nitrate to obtain gray precipitate, stirred at 400rpm, aged for 20min, collected samples were washed with deionized water, then centrifuged at 8000rpm, washed and centrifuged repeatedly for 4 times, dried in an oven at 90°C for 18h to obtain nano-copper-based bismuth Dimensional sheet-like cerium oxide nanomaterials.

Embodiment 3

[0059] Disperse 0.3g of nano-copper powder in 4ml of 15% hydrogen peroxide, soak for 15min, add 10ml of 10% ammonia water, stir in the beaker at 400rpm for 30min, the mixed solution appears light blue, add 2ml of the mixed solution dropwise The mass fraction is 30% cerium nitrate to obtain a gray precipitate, stir at 400rpm, and after aging for 20min, collect the sample and wash it with deionized water, then centrifuge at 7000rpm, repeat the washing and centrifugation for 5 times, and dry in an oven at 100°C for 12h to obtain nano-copper-based bismuth Dimensional sheet-like cerium oxide nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com