Water inflow insulating pipe and electric water heater

An insulating pipe and water inlet technology, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve problems such as failure to meet the normal bathing requirements of users, generation of scale, and turbulent water flow in the inner tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

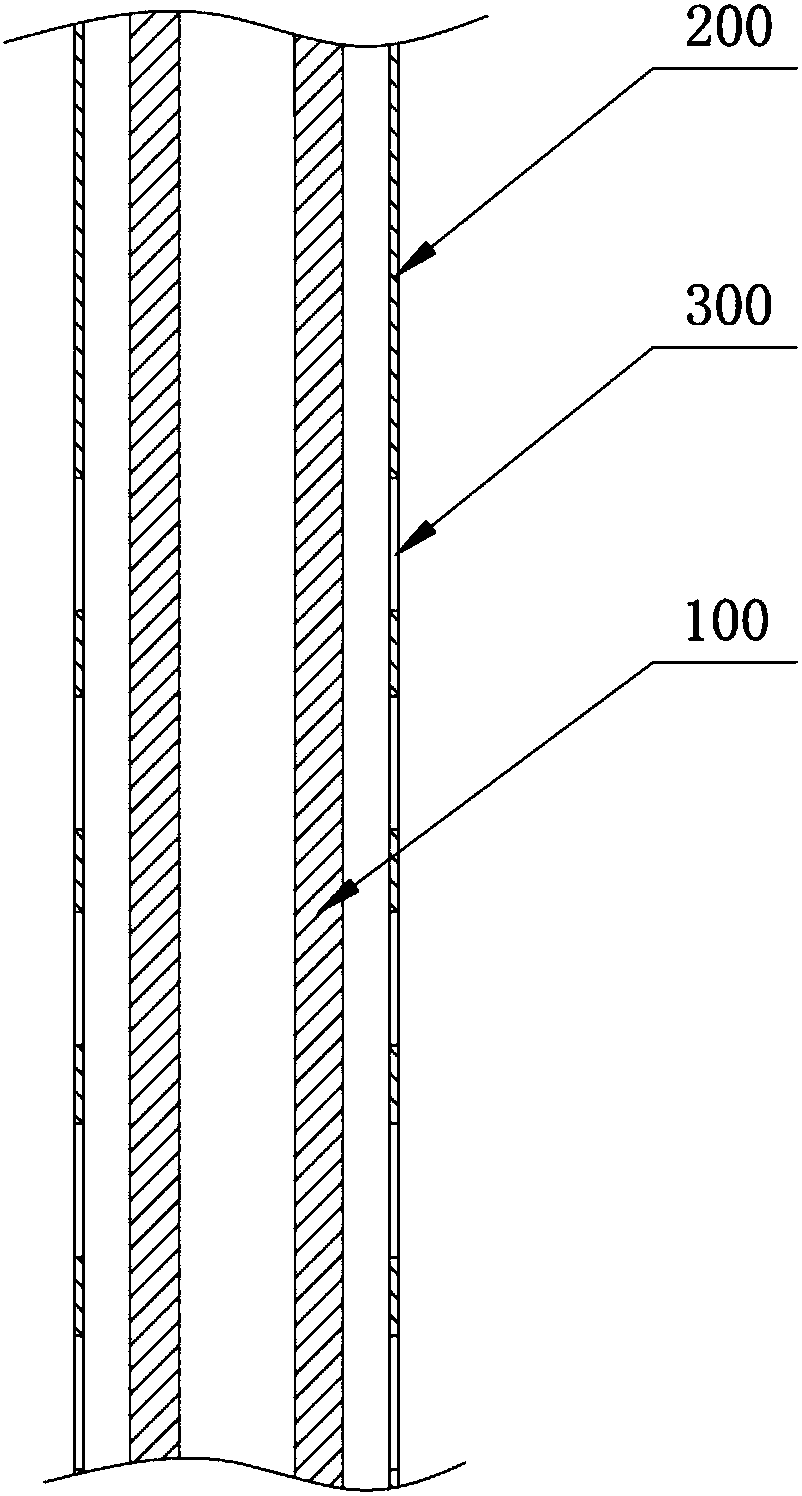

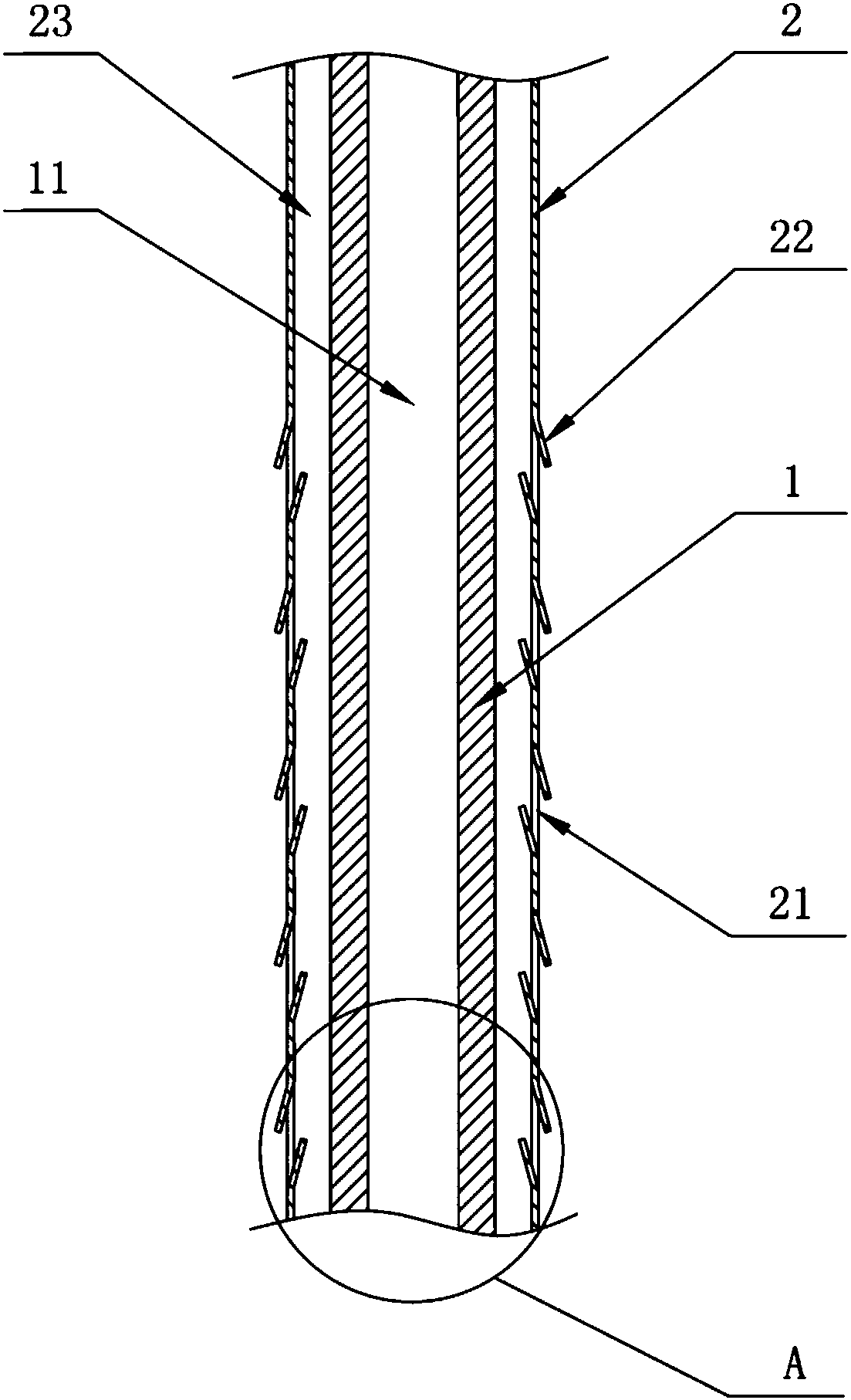

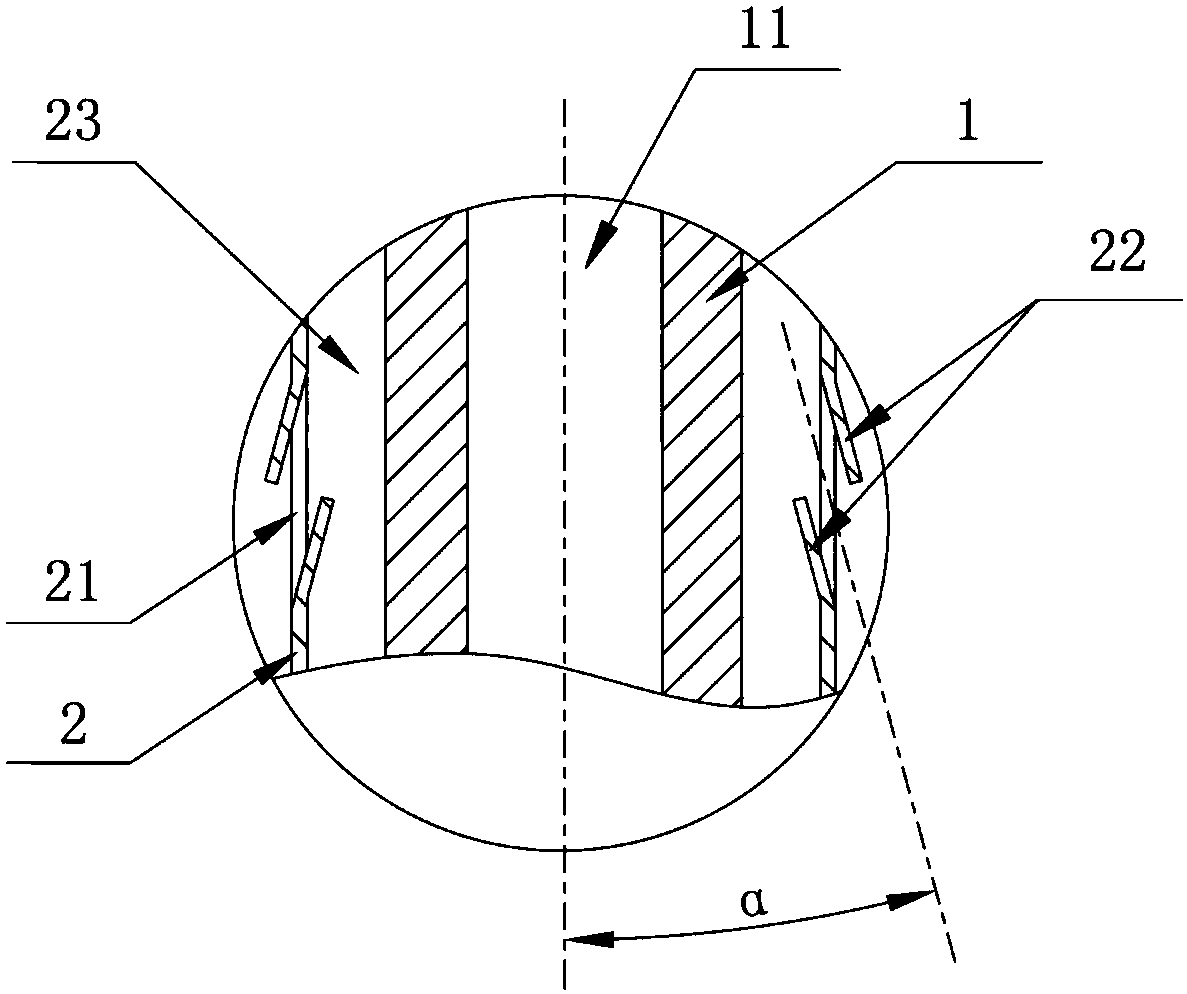

[0024] The present invention provides a water inlet insulating pipe 10, which can be used in conjunction with an inner tank 20 of an electric water heater, such as figure 2 and image 3 As shown, the water inlet insulating pipe 10 includes an insulating pipe 1 and a water inlet liner 2. On the wall of the lower end of the water inlet liner 2, there are several water outlets 21 arranged obliquely downward. Specifically, the water inlet liner 2 It is sleeved outside the insulating tube 1 and forms a water flow channel 23 between the insulating tube 1. There is a channel 11 inside the insulating tube 1. The tap water flows into the water flow channel 23 through the channel 11 of the insulating tube 1, and finally passes through the water outlet 21. Flow to the lower end of the inlet liner 2.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com