Embroidery machine, in particular shuttle embroidery machine

An embroidery machine and embroidery technology, which are applied to the mechanism of the embroidery machine, the mechanism that cuts off the thread in the embroidery machine, and the sewing machine, etc., can solve the problems of large thread consumption, increased wear and vibration of the embroidery machine, etc., so as to simplify the modification work and shorten the downtime. Time and spare parts replacement cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

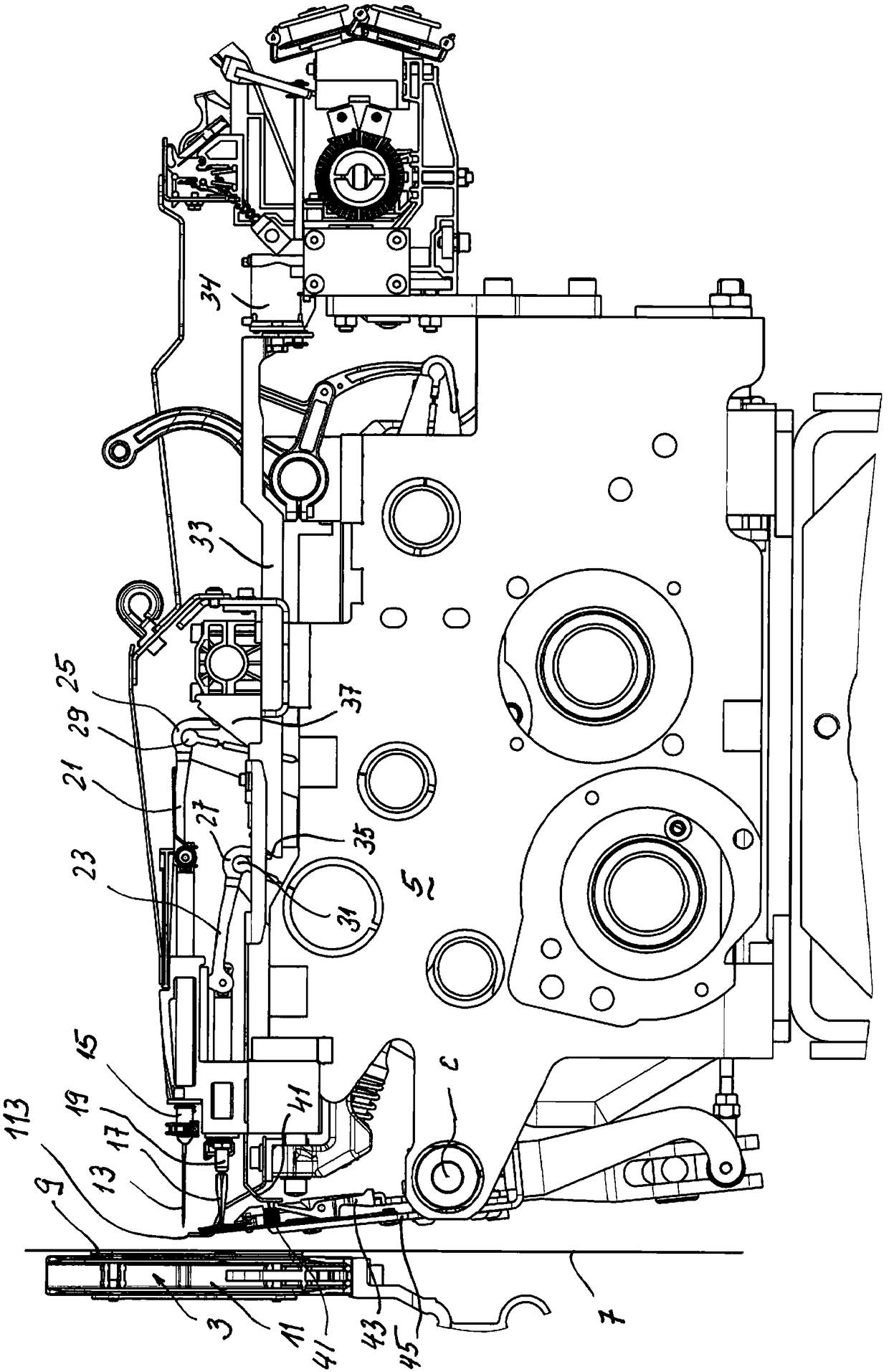

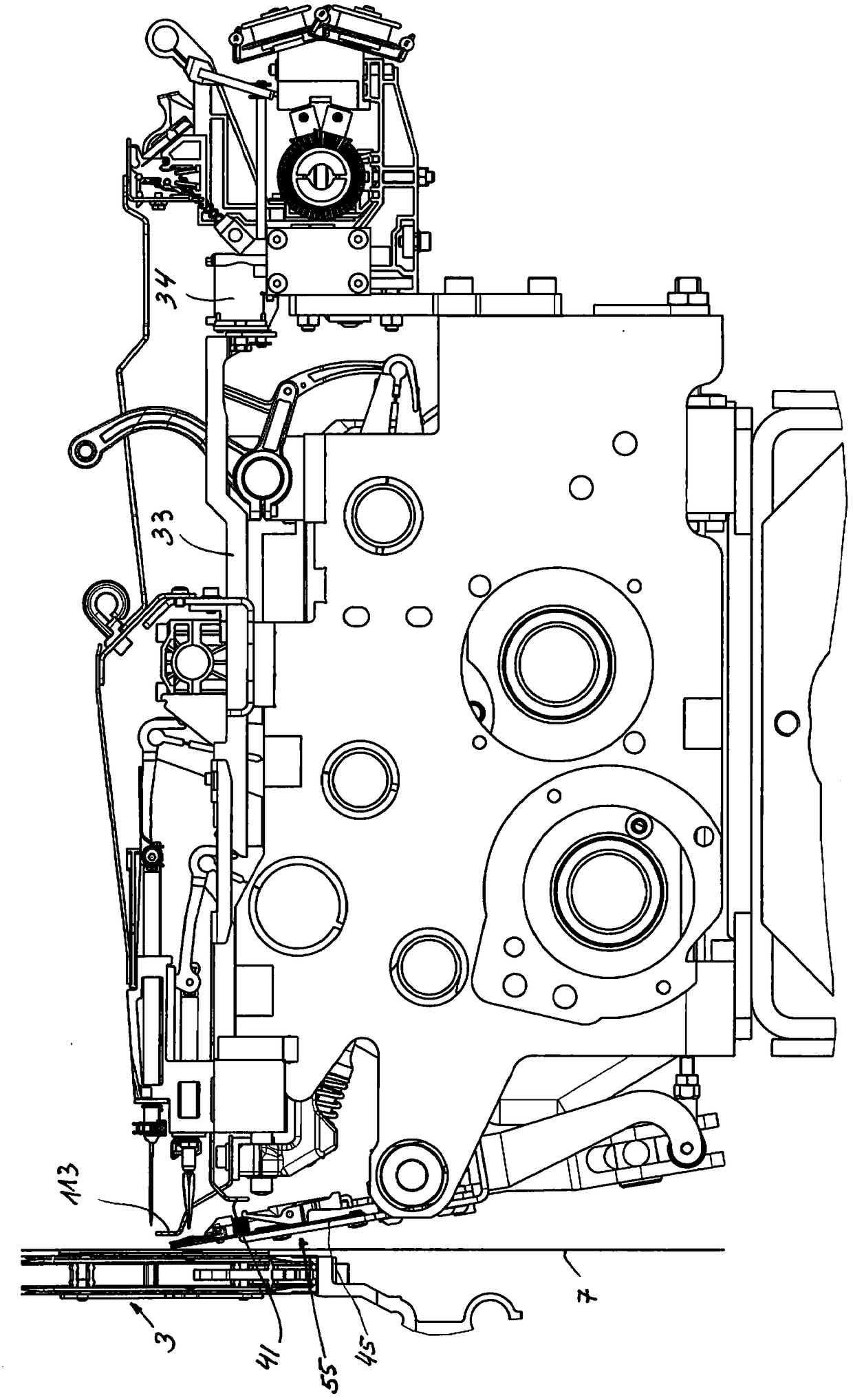

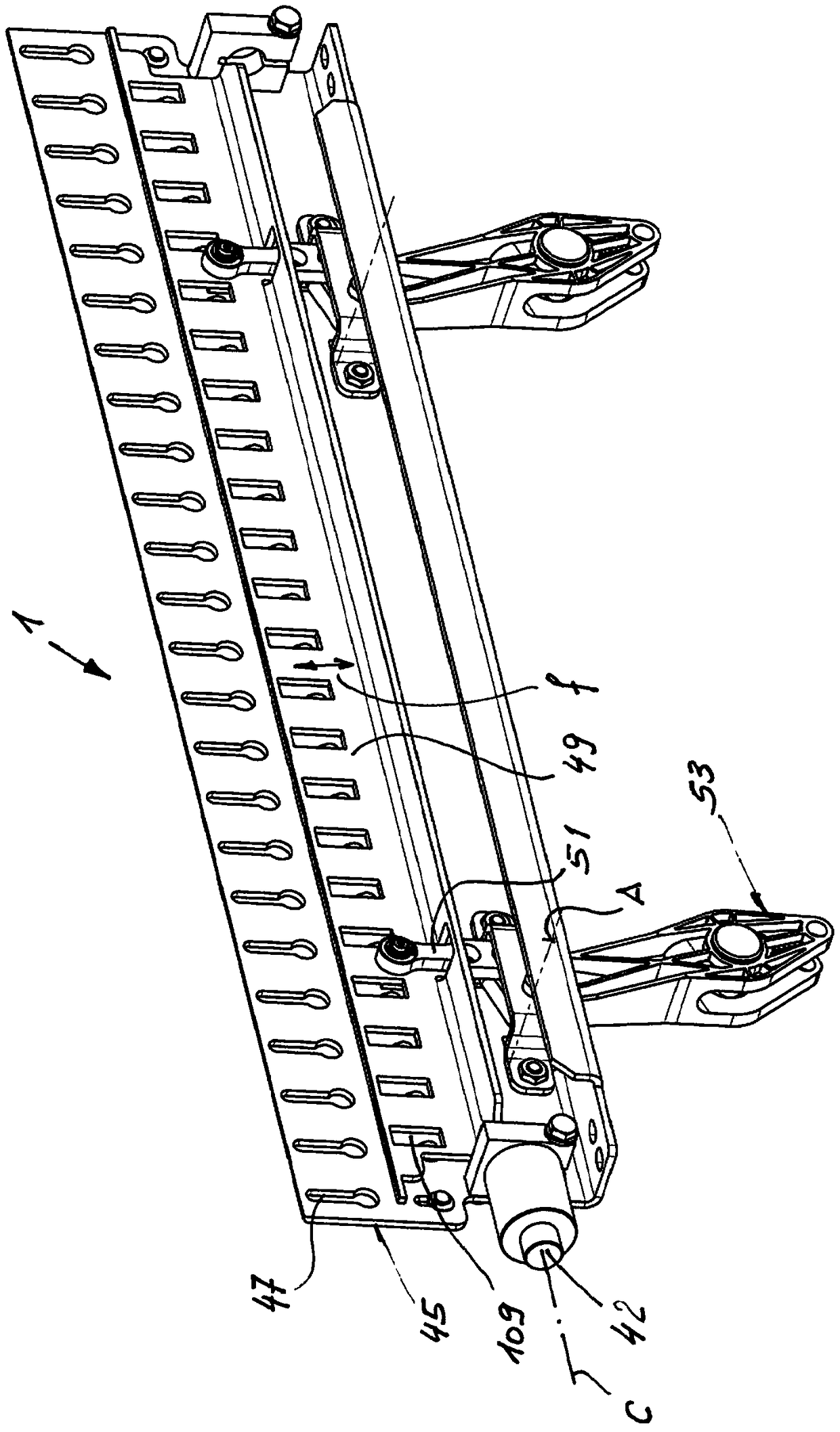

[0029] exist figure 1 and figure 2 In, in order to understand the present invention, the necessary components in a large shuttle car embroidery machine are described. In these figures, it is especially clear to see the Between 3 and the needle car 5 is an embroidery thread cutting and clamping device for cutting and clamping needle thread or upper thread—hereinafter referred to as embroidery thread cutting and clamping device 1 . shuttle track 3 is movable around an axis not shown here to facilitate access to the embroidery base 7 between the embroidery hole plate 9 and the needle 15. On the embroidery base plate 7 and the shuttle rail An embroidery orifice 9 is arranged between the 3. For better visibility, the shuttle track 3. The shuttle car in the shuttle car track 11 is omitted.

[0030] On the right side of the embroidery base plate 7, above the needle 13, it can be seen that it is clamped by the needle holder 15. Below the needle 13 is a drill 17 which is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com